Method for rolling large-sized fine grain magnesium alloy plate

A magnesium alloy, large-scale technology, applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of poor plastic deformation ability, poor comprehensive performance, and easy brittle cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

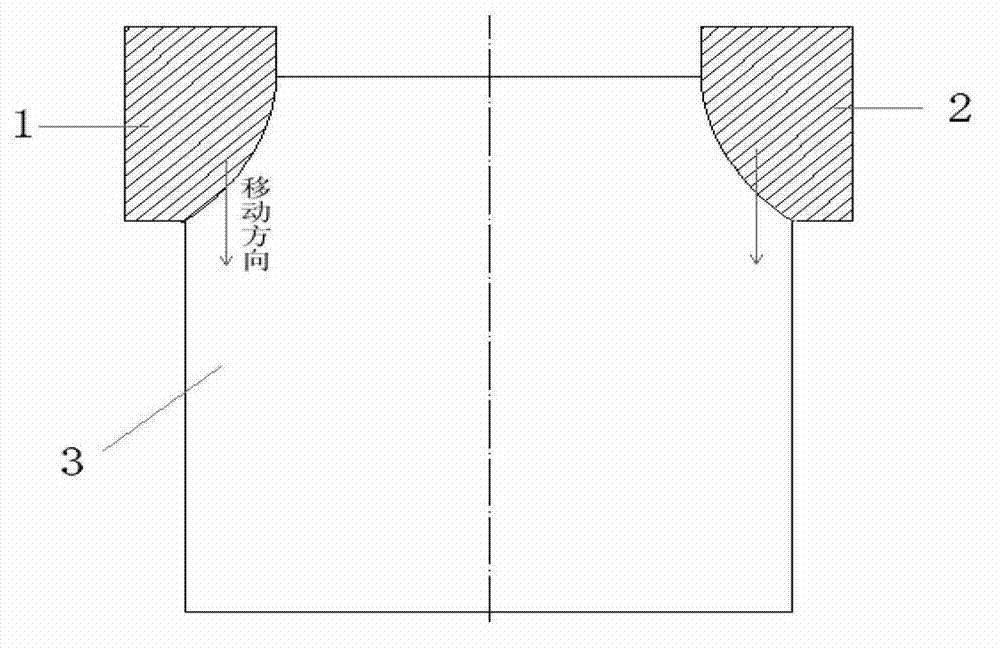

[0036] The sample was prepared from a standard AZ31 magnesium alloy slab, with a grain diameter of about 26.7 μm, such as Figure 5 As shown, the geometric size is 10×30×25 (H×B×L). Firstly, the magnesium alloy slab is heated to 350°C and placed in figure 1 Between the two hammerheads shown, compression deformation occurs along the width direction of the slab, and the width decreases and the thickness increases. Each relative compression rate ε B =△B / B O =15%, true response e=ln(B 0 / B)=0.15. Such as Figure 6 shown.

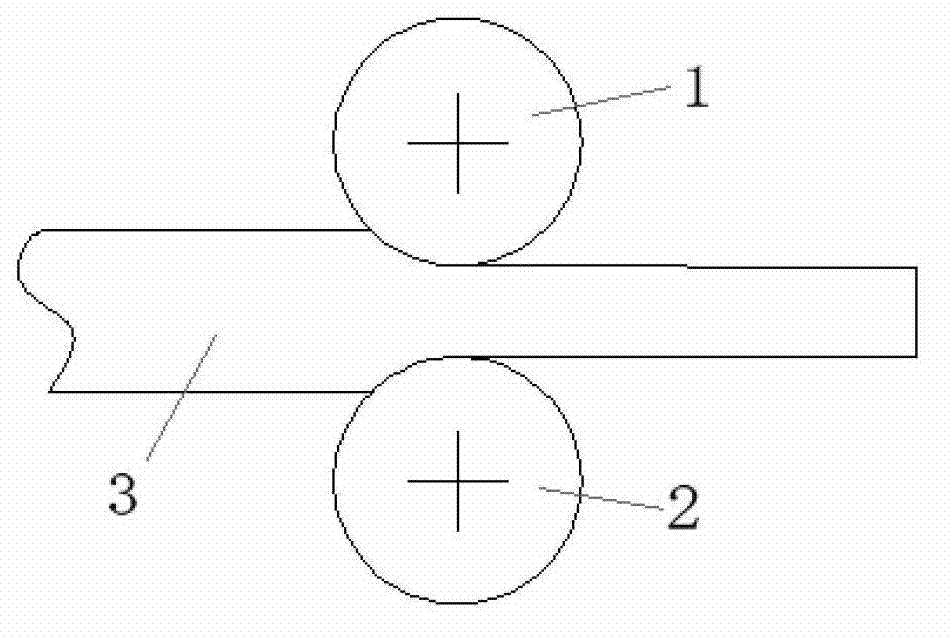

[0037] In the second step, the magnesium alloy slab 3 after compression deformation is rotated horizontally by 90°, such as figure 2 As shown, rolling is carried out along its width direction, and the thickness of the slab returns to the original thickness after rolling.

[0038] The third step is to compress the slab along the length direction, rotate it horizontally by 90° and then roll it. The compression and rolling methods are the same as in the wi...

Embodiment 2

[0041] The sample was prepared from a standard AZ31 magnesium alloy slab, with a grain diameter of about 26.7 μm, such as Figure 5 As shown, the geometric size is 10×50×40 (H×B×L). Firstly, the magnesium alloy slab is heated to 350°C and placed in such as figure 1 Between the two hammerheads shown, compression deformation occurs along the width direction of the slab, and the width shrinks and the thickness increases. Each relative compression rate ε B =△B / B O =33%, true response e=ln(B 0 / B)=0.4.

[0042]In the second step, the magnesium alloy slab 3 after compression deformation is rotated horizontally by 90°, such as figure 2 As shown, the slab is rolled on a rolling mill along its width direction, and the thickness of the slab returns to its original thickness after rolling.

[0043] The third step is to compress the slab along the length direction, rotate it horizontally by 90° and then roll it. The method of compression and rolling, the amount of deformation is th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com