Method for preparing PTFE/PPS micro powder for the coating of the non-stick pan

A non-stick pan and micro-powder technology, which is applied in coating, grain processing, etc., can solve the problems of human harm and achieve high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

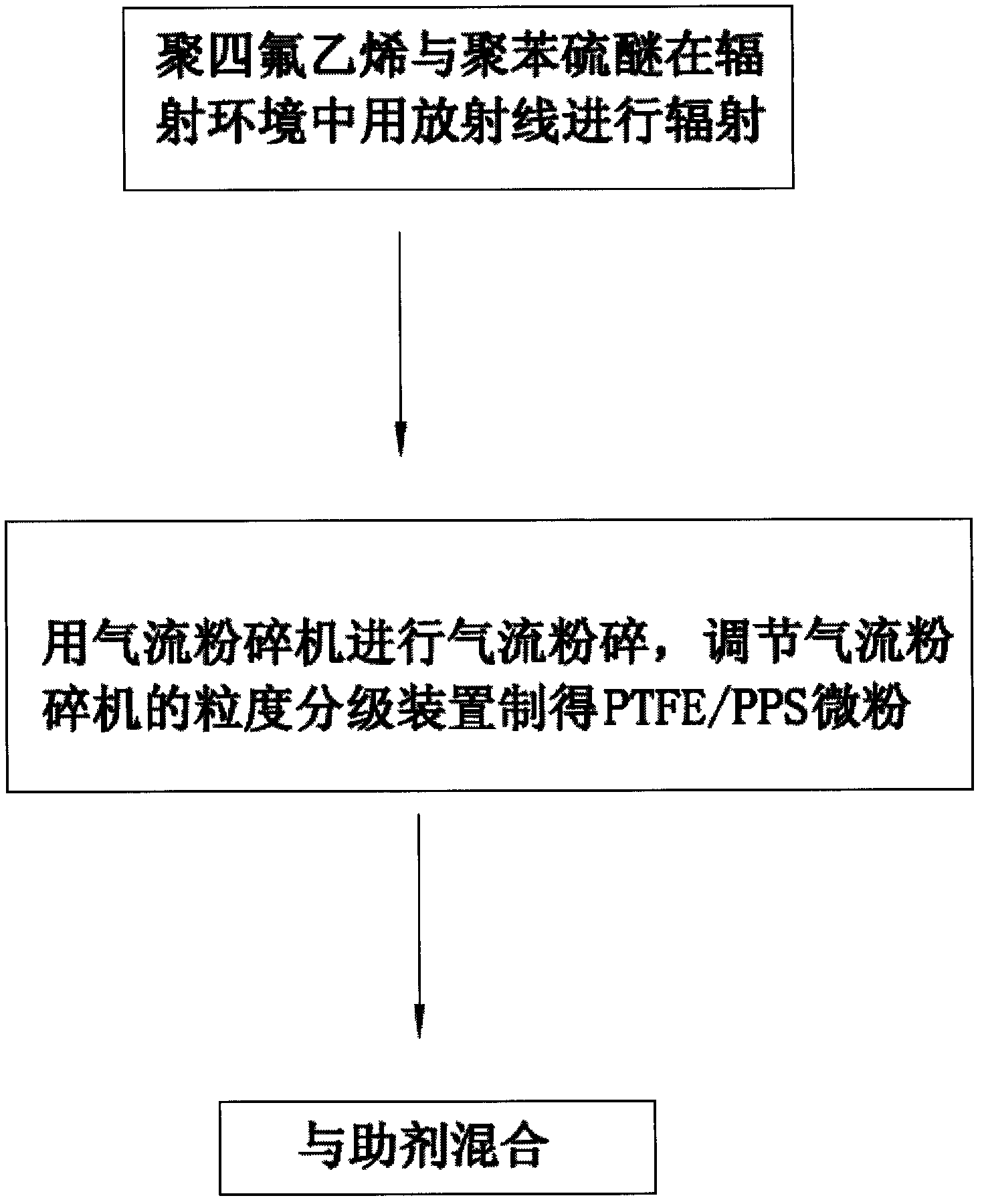

[0014] Such as figure 1 Shown, the preparation method of PTFE / PPS micropowder for non-stick pan coating provided by the invention, concrete steps are as follows:

[0015] a), irradiating polytetrafluoroethylene and polyphenylene sulfide raw materials with radiation in a radiation environment;

[0016] b) Airflow pulverization of the irradiated powder at room temperature with an airflow mill, adjusting the particle size classification device of the airflow mill to obtain polytetrafluoroethylene and polyphenylene sulfide fine powder;

[0017] c), mixing the obtained polytetrafluoroethylene with polyphenylene sulfide micropowder and additives.

[0018] The mass ratio of PTFE and PPS can be adjusted according to different needs. The radiation environment in step a) is air, the radiation is r-rays, the radiation source is 60Co, and the radiation dose of radiation is 80KGy. The pressure of the jet mill in step b) is 800KPa, and the particle diameter of the PTFE / PPS micropowder fo...

Embodiment 2

[0020] Such as figure 1 Shown, the preparation method of PTFE / PPS micropowder for non-stick pan coating provided by the invention, concrete steps are as follows:

[0021] a), irradiating polytetrafluoroethylene and polyphenylene sulfide raw materials with radiation in a radiation environment;

[0022] b) Airflow pulverization of the irradiated powder at room temperature with an airflow mill, adjusting the particle size classification device of the airflow mill to obtain polytetrafluoroethylene and polyphenylene sulfide fine powder;

[0023] c), mixing the obtained polytetrafluoroethylene with polyphenylene sulfide micropowder and additives.

[0024] The mass ratio of PTFE and PPS can be adjusted according to different needs. The radiation environment in step a) is air or inert gas, the radiation is electron beam, the radiation source is 137Cs, and the radiation dose of radiation is 90KGy. The pressure of the jet mill in step b) is 1200KPa, and the particle diameter of the P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com