Ink for printing and directly making plate used in nanometer material and preparation method thereof

A nanomaterial and ink technology, which is applied to the ink and its preparation field of nanomaterial printing direct plate making technology, can solve problems such as the decrease of plate making accuracy, and achieve the effects of good resolution, reduction of chemical pollution and post-processing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

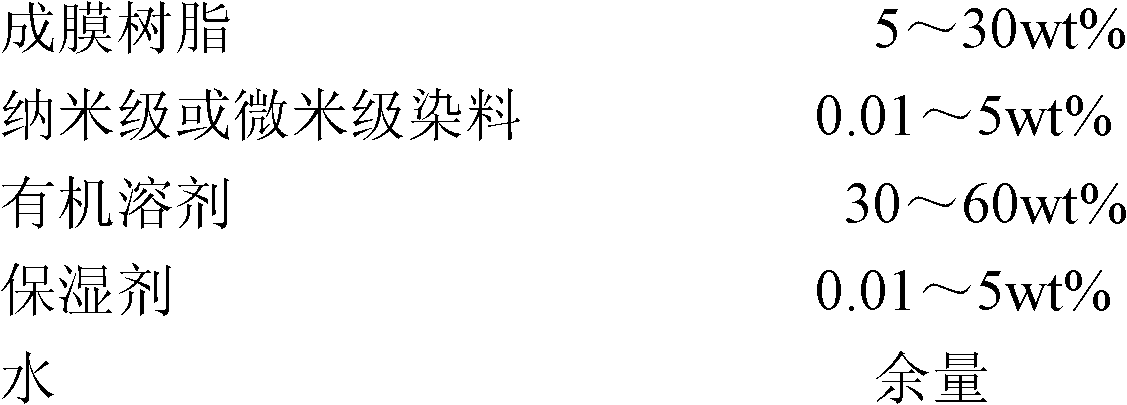

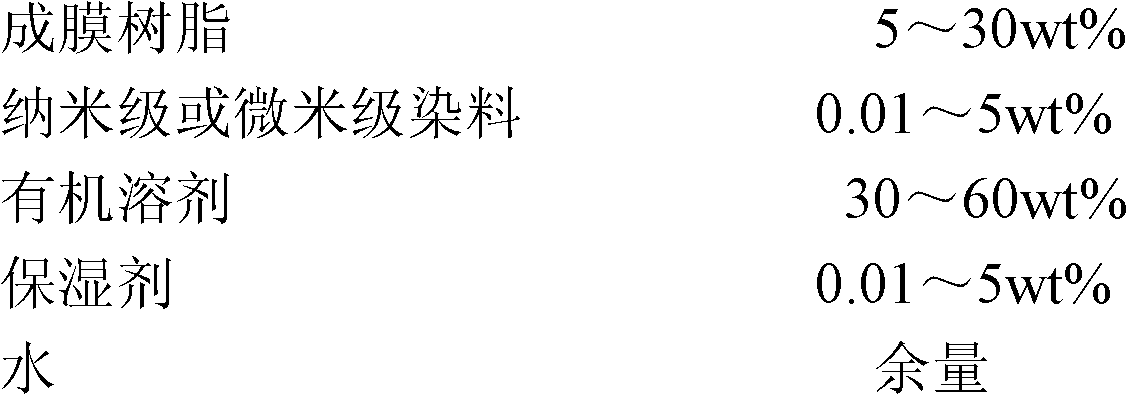

Method used

Image

Examples

Embodiment 1

[0024] With the phenolic resin that accounts for ink total amount 30wt%, the tert-butanol of 60wt%, the propylene glycol of 0.01wt%, the dyestuff acid blue 9 (particle diameter: 2000nm) of 5wt% and the deionized water of remainder, at room temperature Stir and mix for 5 hours, and then filter the mixed solution with a sand core funnel and a filter membrane with a micron pore size to remove undissolved particles and impurities, and the obtained filtrate is ink for direct plate-making of nanomaterial printing.

Embodiment 2

[0026] With the phenolic resin of 5wt% total ink, the tert-butanol of 30wt%, the propylene glycol of 0.01wt%, the black dye SP (particle diameter of particle: 2000nm) of 0.01wt% and the deionized water of remainder, at room temperature Stir and mix for 6 hours, and then filter the mixed solution with a sand core funnel and a filter membrane with a micron pore size to remove undissolved particles and impurities, and the obtained filtrate is ink for direct plate-making of nanomaterial printing.

Embodiment 3

[0028] With the phenolic resin of 15wt% total ink, the tert-butanol of 50wt%, the propylene glycol of 0.2wt%, the black dye SP (particle size: 1000nm) of 0.5wt% and the deionized water of remainder, at room temperature Stir and mix for 4 hours, then filter the mixed solution with a sand core funnel and a filter membrane with a micron pore size to remove undissolved particles and impurities, and the obtained filtrate is ink for direct plate-making of nanomaterial printing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com