Tape cutting apparatus, tape printing apparatus having the same, and method of controlling stepping motor

A technology of stepping motor and cutting device, applied in printing device, printing and other directions, can solve the problems of large-scale device, complicated device, and cutting into the main belt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

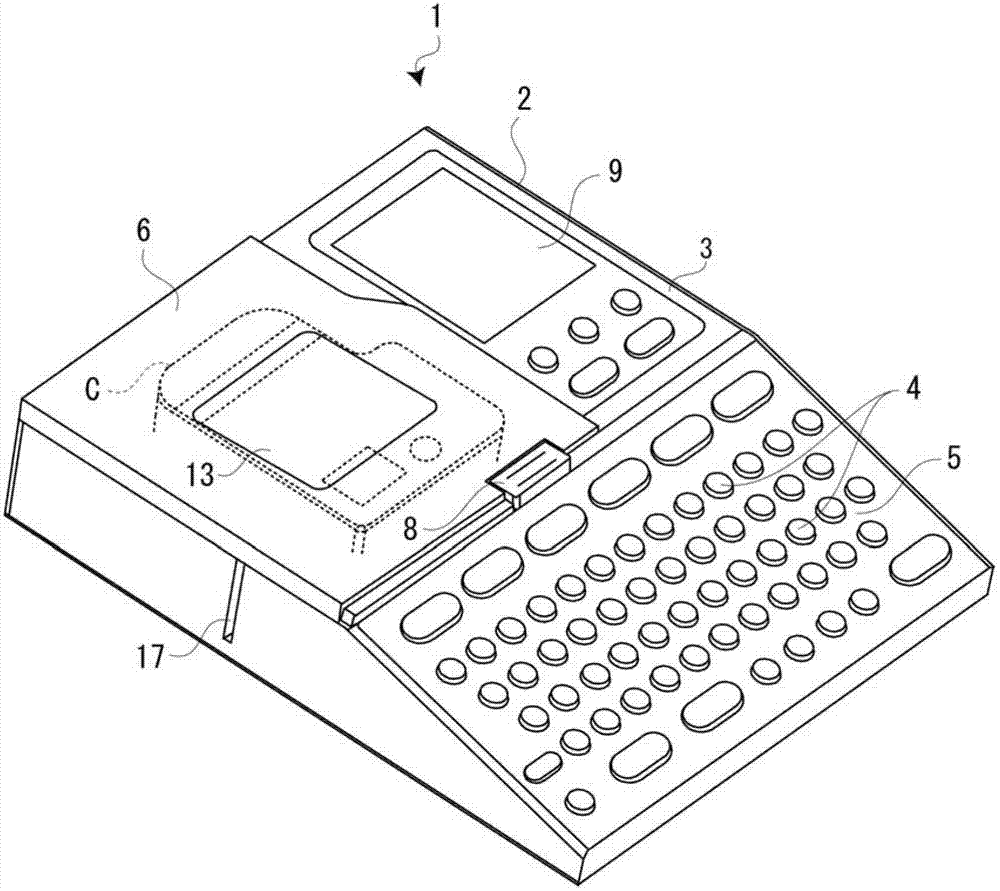

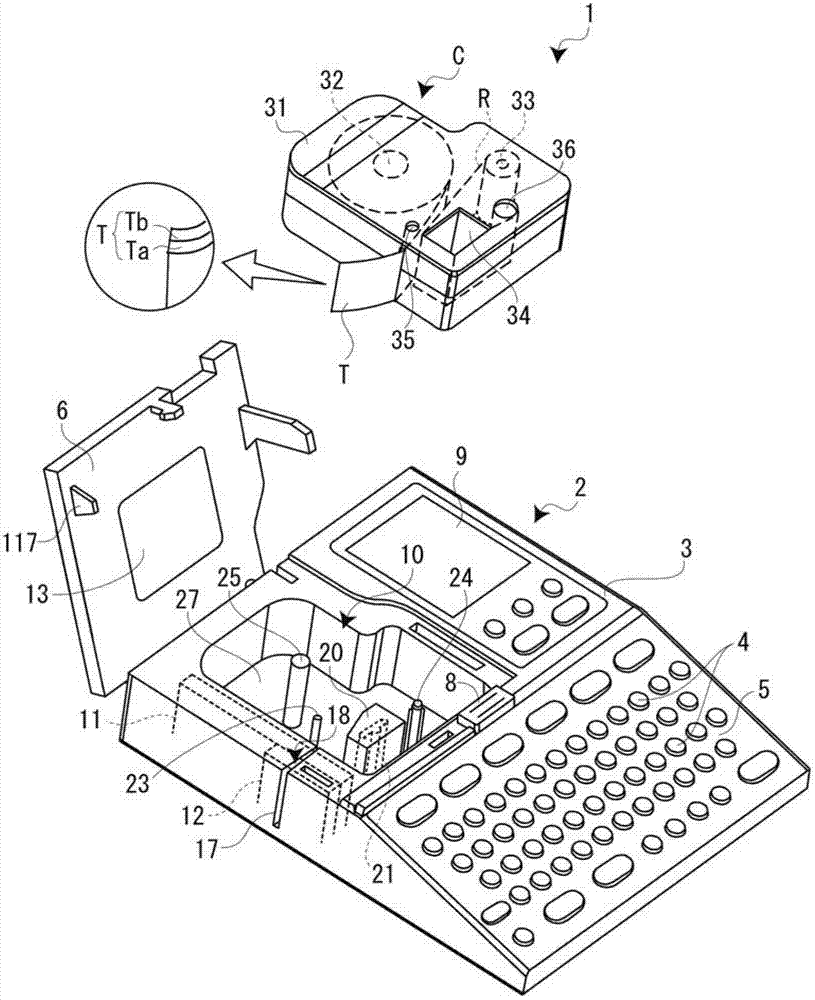

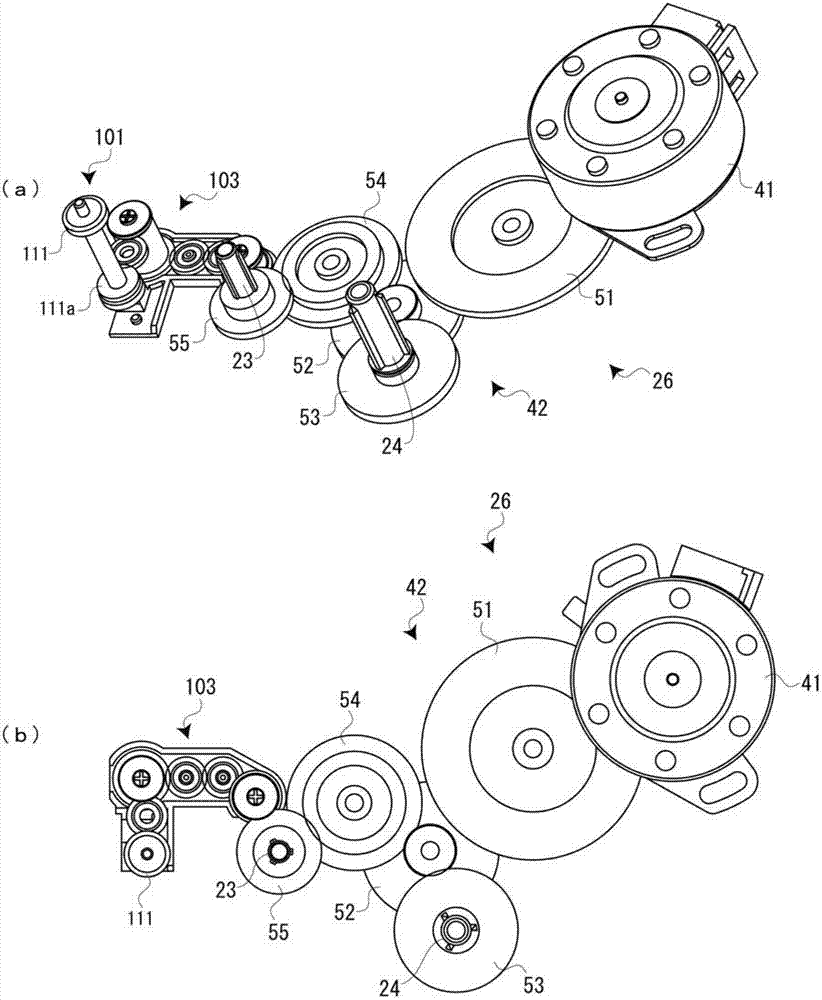

[0036] A tape cutting device, a tape printing device including the tape cutting device, and a method of controlling a stepping motor according to an embodiment of the present invention will be described below with reference to the drawings. In the embodiment, a tape printing device having a half-cut function is exemplified. This tape printing apparatus conveys and prints a printing tape (processing tape) as an object to be printed, cuts the printing tape in half appropriately, and simultaneously cuts the printed portion of the printing tape to produce a label. And in this embodiment, "front", "back", "left", "right", "up", "down" refer to the direction observed by the user using the tape printing device (front view).

[0037] Such as figure 1 with figure 2 As shown, the tape printing apparatus 1 has an apparatus main body 2 for printing on a printing tape T, and a tape cassette C that accommodates the printing tape T and ink ribbon R and is detachably attached to the appara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com