Method capable of automatically eliminating motion accumulated error of robot

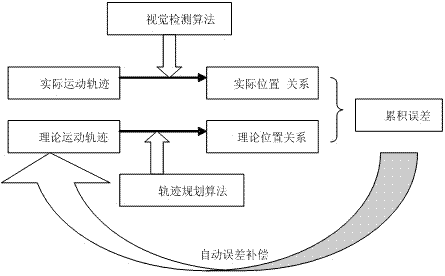

A technology of robot motion and accumulating errors, applied in manipulators, manufacturing tools, etc., can solve the problems of deviation between the actual motion trajectory of the robot and the theoretical motion trajectory, blocking the continuity of processing operations, affecting the efficiency and accuracy of production and processing, etc. Achieve the effect of ensuring uninterrupted continuous operation, ensuring continuity and efficiency, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] During the processing operation of the robot, its movement trajectory is controlled by a preset motion control program. Generally, after the robot has been working for a period of time, it will deviate from the original movement trajectory, making it difficult for the robot and the workpiece to always maintain the same position. In order not to affect the processing operation, it is necessary to reposition the zero position of the robot to eliminate the cumulative error of the robot movement. The zero calibration in the prior art needs to shut down the robot first, and then perform the zero calibration after making it stop working, which leads to the interruption of the processing operation and affects the continuity and high efficiency of the processing operation. The present invention aims at the defects of the existing technology, based on the fact that the motion of the robot is the essential characteristic of the motion of each joint, and finds another way of thinki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com