Vessel comprising a stowable magnus-effect rotor

A ship and rotor technology, applied in ship propulsion, transportation and packaging, ship construction, etc., can solve the problem of no open drive device, etc., and achieve the effect of reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

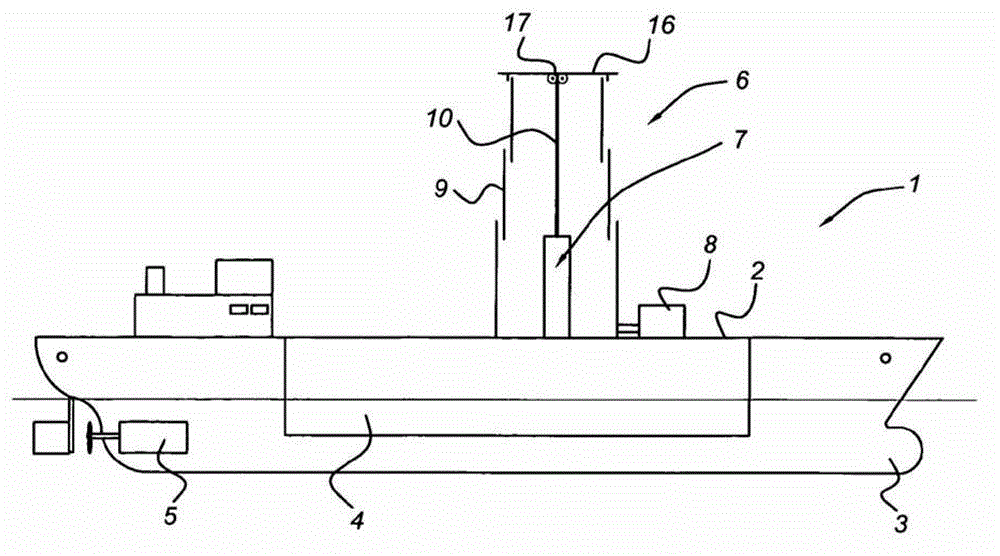

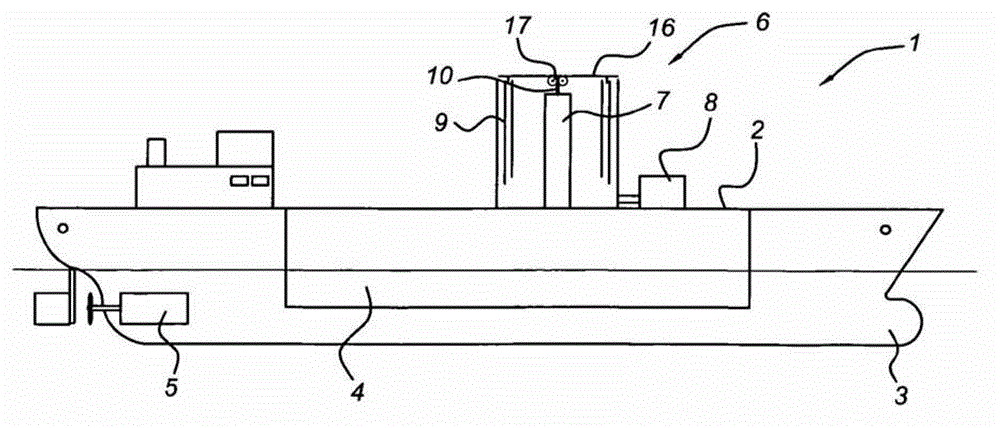

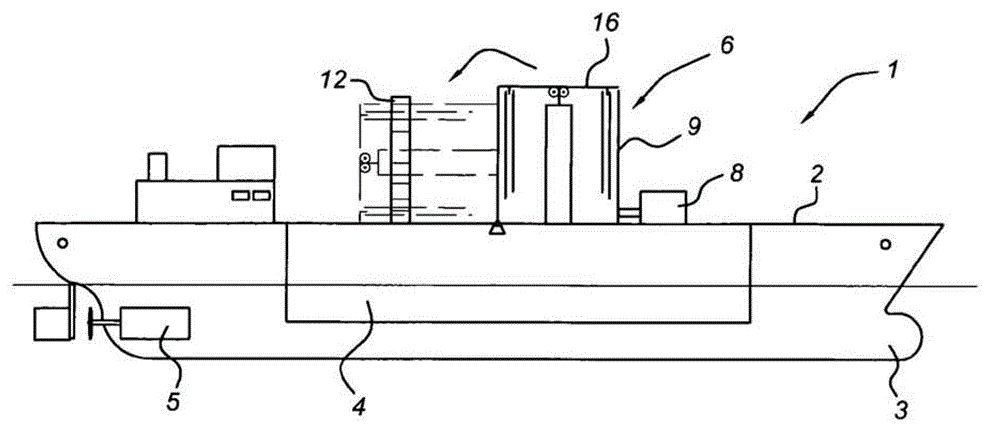

[0065] figure 1A schematic side view of a vessel according to an embodiment of the invention is shown, equipped with a telescopically retractable rotor in an extended operating state; the vessel 1 is provided with a cargo compartment 4 for storing cargo. The vessel 1 is also equipped with a thruster system 5 for propelling the vessel 1 . The hull 3 includes the aforementioned cargo compartment 4 . The upper part of the hull 3 is formed by the deck 2 . A cylindrical rotor 6 is placed on the deck 2 . A rotary drive 8 is also located on the deck 2 for rotating or spinning the rotor 6 to a desired rotational speed. The rotor 6 itself comprises several tubular sections 9 . The tubular sections 9 are telescopically fitted to each other, their longitudinal axes being substantially in line with each other and their outer surfaces partially overlapping. Along the longitudinal axis of the rotor 6, a displacement element 7 is placed for extending the rotor 6 to its operative state a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com