Method for bonding circuit board reinforcing patches

A technology for reinforcing sheets and circuit boards, which is applied to printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of low lamination efficiency, poor lamination accuracy, and high production costs, so as to save production costs and improve lamination. Accuracy, the effect of improving the bonding production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

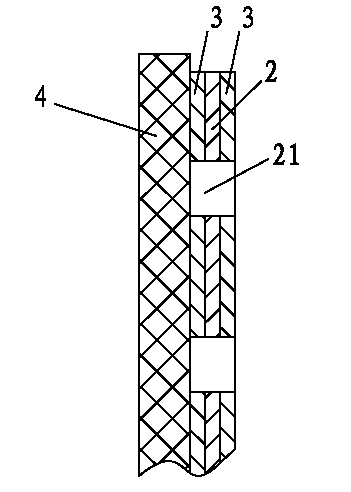

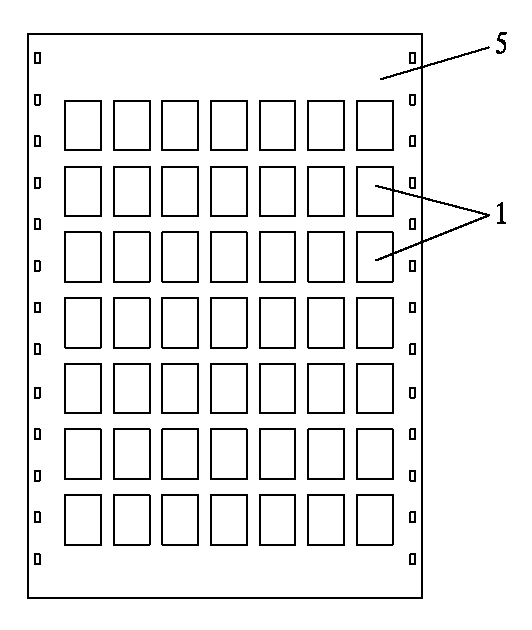

[0020] Embodiment 1: circuit board reinforcing sheet laminating method of the present invention, it comprises the following steps: A, the step of making adhesive layer 2: stick release paper 3 on the adhesive backed jig plate 4 that is drilled with positioning pin holes , and then attach the adhesive layer 2 that needs to be backed to the reinforcing sheet 1 on the release paper 3, and then use a laser cutting machine to open multiple windows 21 on the adhesive layer 2, and cut the adhesive layer 2 at the same time. out the positioning pin hole. The adhesive layer 2 is an adhesive tape or an adhesive sheet. A plurality of windows 21 are arranged in a matrix, and the size of the windows 21 is smaller than that of the reinforcing sheet 1 . The adhesive layer 2 can be a single-layer structure. After step A, only one side of the adhesive layer 2 has a layer of release paper 3; the adhesive layer 2 can also have a layer of release paper 3. There is a layer of release paper 3 on b...

Embodiment 2

[0025] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the length of the receiving groove 61 is 1 mil longer than the length of the reinforcing sheet 1 , and the width of the receiving groove 61 is 1 mil larger than the width of the reinforcing sheet 1 .

Embodiment 3

[0026] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the length of the receiving groove 61 is 3 mil longer than the length of the reinforcing sheet 1 , and the width of the receiving groove 61 is 3 mil larger than the width of the reinforcing sheet 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com