Biomimetic preparation method for passivation layer on surface of crystalline silicon solar cell

A technology of solar cells and passivation layers, which is applied in the manufacture of circuits, electrical components, and final products, can solve problems such as high production costs and complex process equipment conditions, reduce production costs, improve minority carrier life and open circuit voltage, and improve Effect of Photoelectric Conversion Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to these specific implementations. Those skilled in the art will realize that the present invention covers all alternatives, modifications and equivalents as may be included within the scope of the claims.

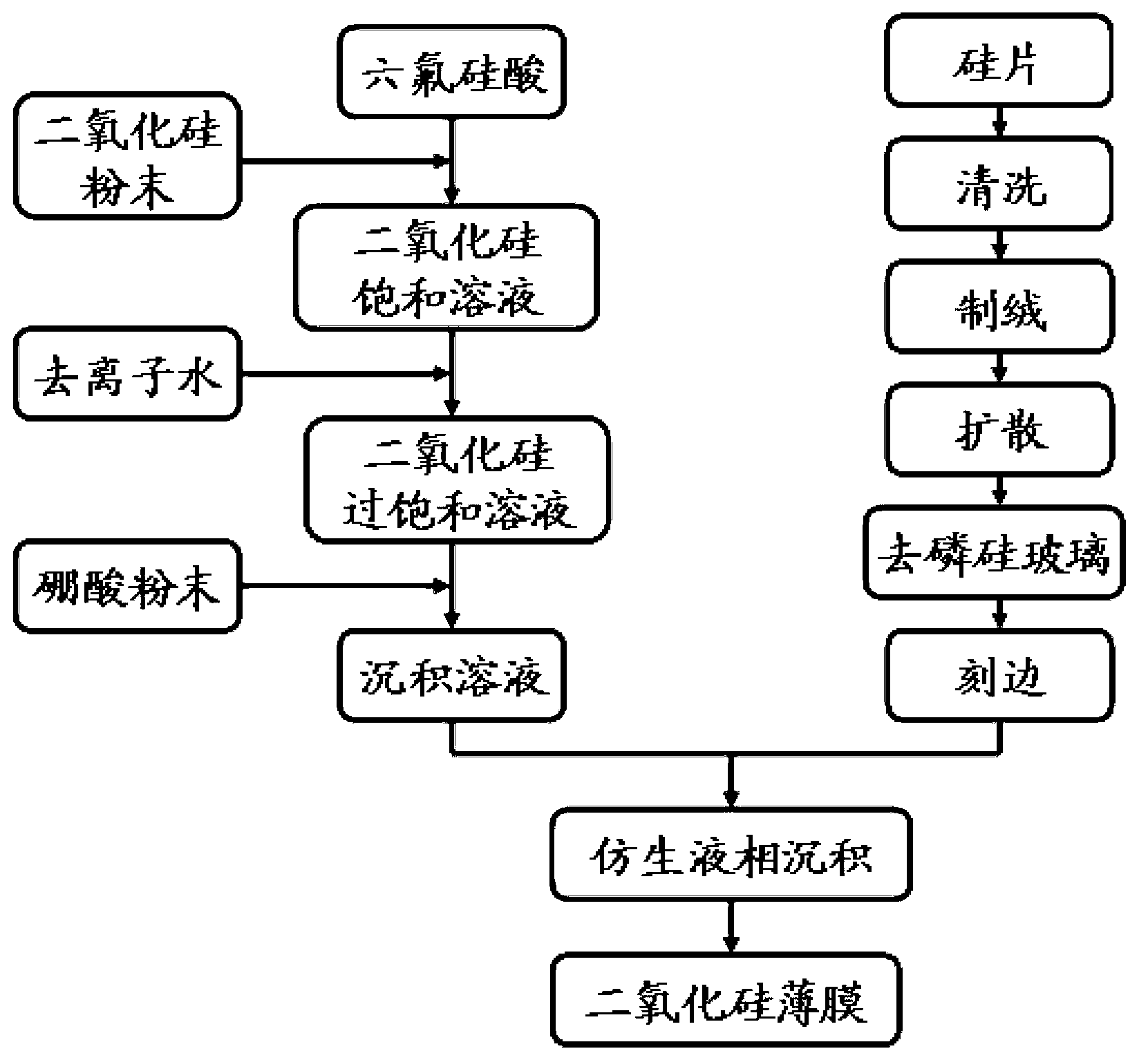

[0029] see figure 1 , the embodiment of the present invention provides a biomimetic preparation method of a passivation layer on the surface of crystalline silicon solar cells, the method includes pretreatment of silicon wafers, preparation of silicon dioxide deposition solution and biomimetic liquid phase deposition of silicon dioxide thin films, detailed below The above three processes are described as follows:

[0030] Step 101: Take a 156mm×156mm polycrystalline silicon wafer, immerse the silicon wafer in a hydrofluoric acid solution with a concentration of 10%, soak for 2 to 3 minutes, and rinse with deionized water;

[0031] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com