Display panel, manufacturing method thereof, and display device

A technology for display panels and array substrates, applied in nonlinear optics, instruments, optics, etc., can solve problems such as poor image quality, prone to light leakage, and reduce the aperture ratio of unit pixels, so as to reduce the width, increase the cost, and improve the aperture rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

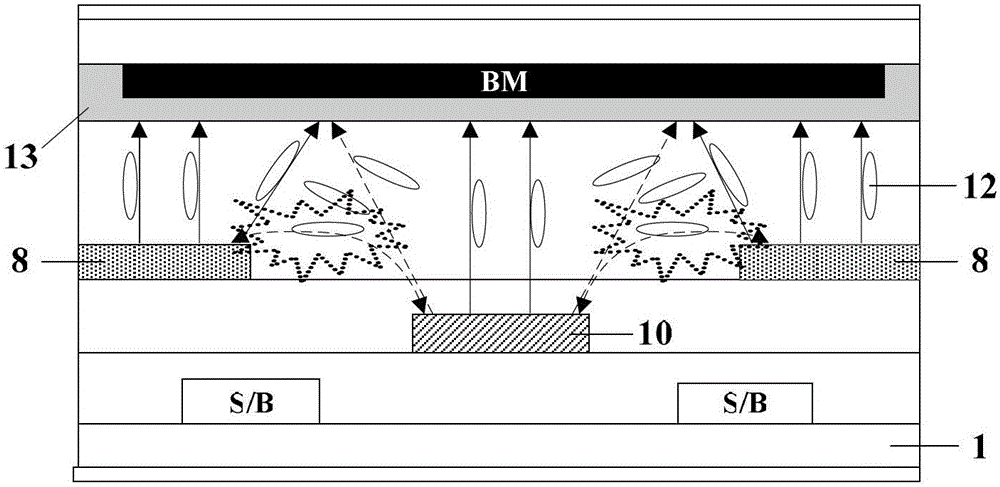

[0055] In this embodiment, the display panel adopts a normally white display panel, that is, when no voltage is applied to the display panel (there is no electric field or a weak electric field is formed between the pixel electrode and the common electrode), the effective display of the display panel corresponding to the liquid crystal molecules area (the display panel can usually be divided into two parts, that is, the effective display area and the peripheral area) transmit light; when a voltage is applied (a strong electric field is formed between the pixel electrode and the common electrode), the effective display area of the display panel corresponding to the liquid crystal molecules does not Translucent.

[0056] In this embodiment, the display panel includes an array substrate and a color filter substrate; the array substrate includes a plurality of gate lines, a plurality of data lines, and a plurality of common electrode lines, and the plurality of gate lines and the...

Embodiment 2

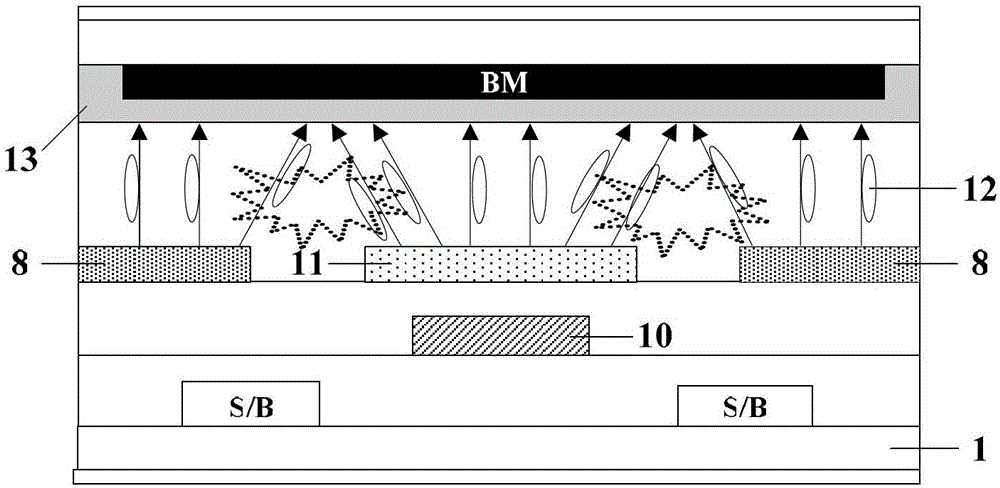

[0082] In this embodiment, the display panel adopts a normally black mode display panel, that is, when no voltage is applied to the display panel (there is no electric field or a weak electric field is formed between the pixel electrode and the common electrode), the effective display of the display panel corresponding to the liquid crystal molecules The area is opaque; when a voltage is applied (a strong electric field is formed between the pixel electrode and the common electrode), the effective display area of the display panel corresponding to the liquid crystal molecules transmits light.

[0083] 1) In this embodiment, the difference between the display panel and the display panel in Embodiment 1 is that the shielding electrode in this embodiment is connected to the common electrode line, so as to ensure that the potential of the shielding electrode is equal to the potential of the common electrode.

[0084] Since the display panel in this embodiment adopts a normally bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com