Cryogenic environment material mechanical performance detection test device

A technology of material mechanics and test equipment, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the limited test capacity, the difficulty in combining the fatigue function of the low-temperature environment box and the test machine, the test temperature range, control and detection accuracy Unable to meet the requirements of tensile and fatigue tests of cryogenic environment materials at the same time, and achieve the effect of large test temperature range and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

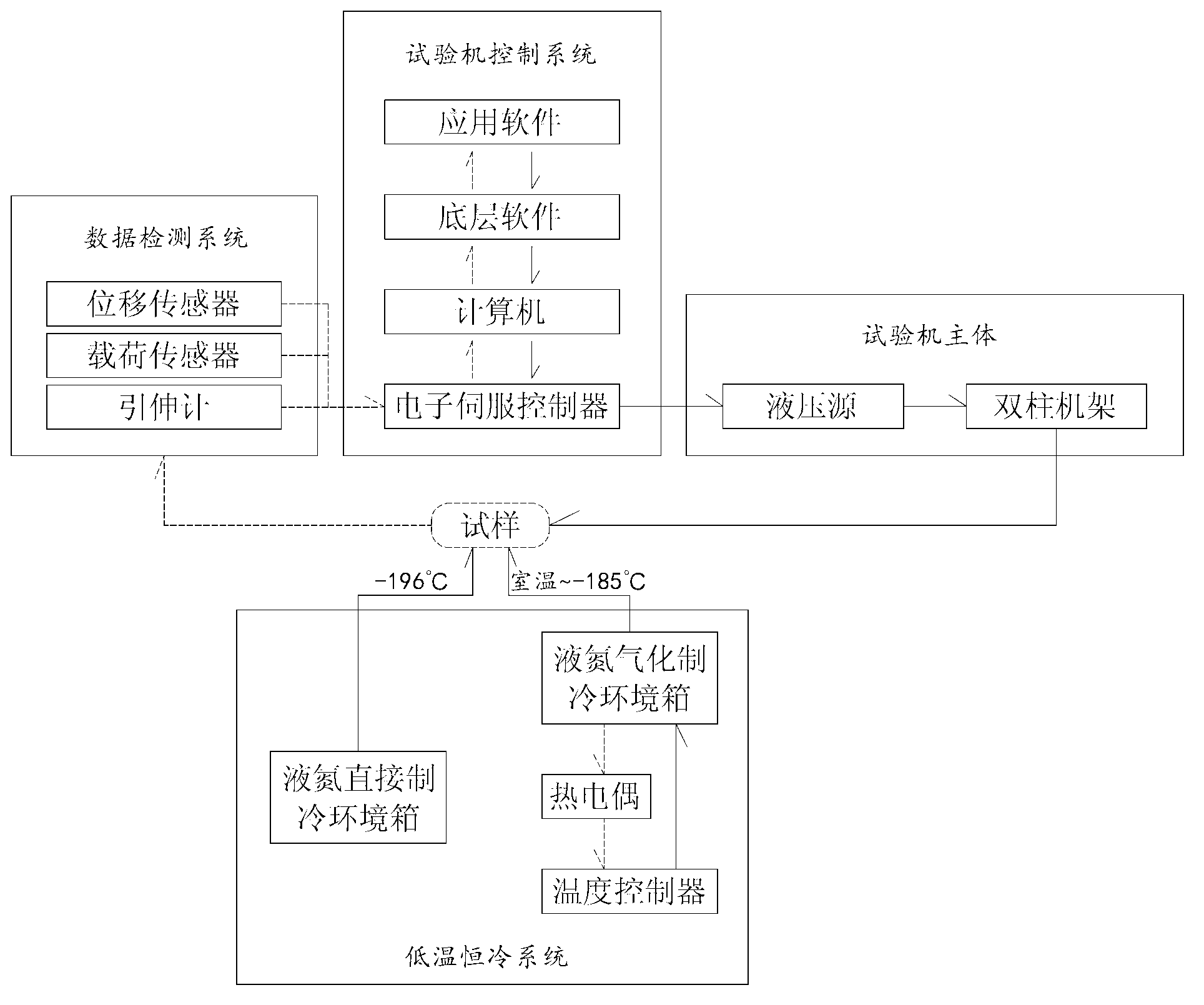

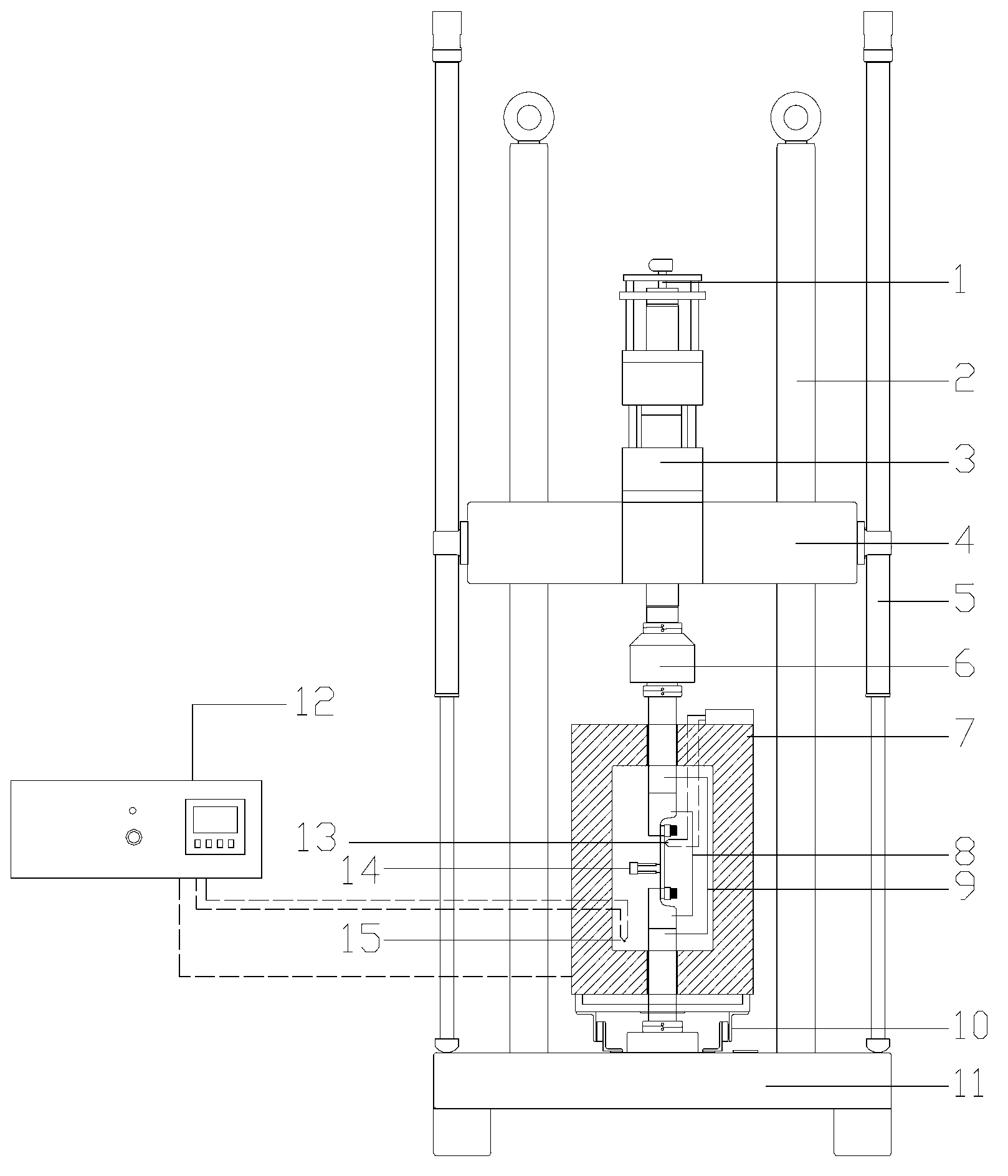

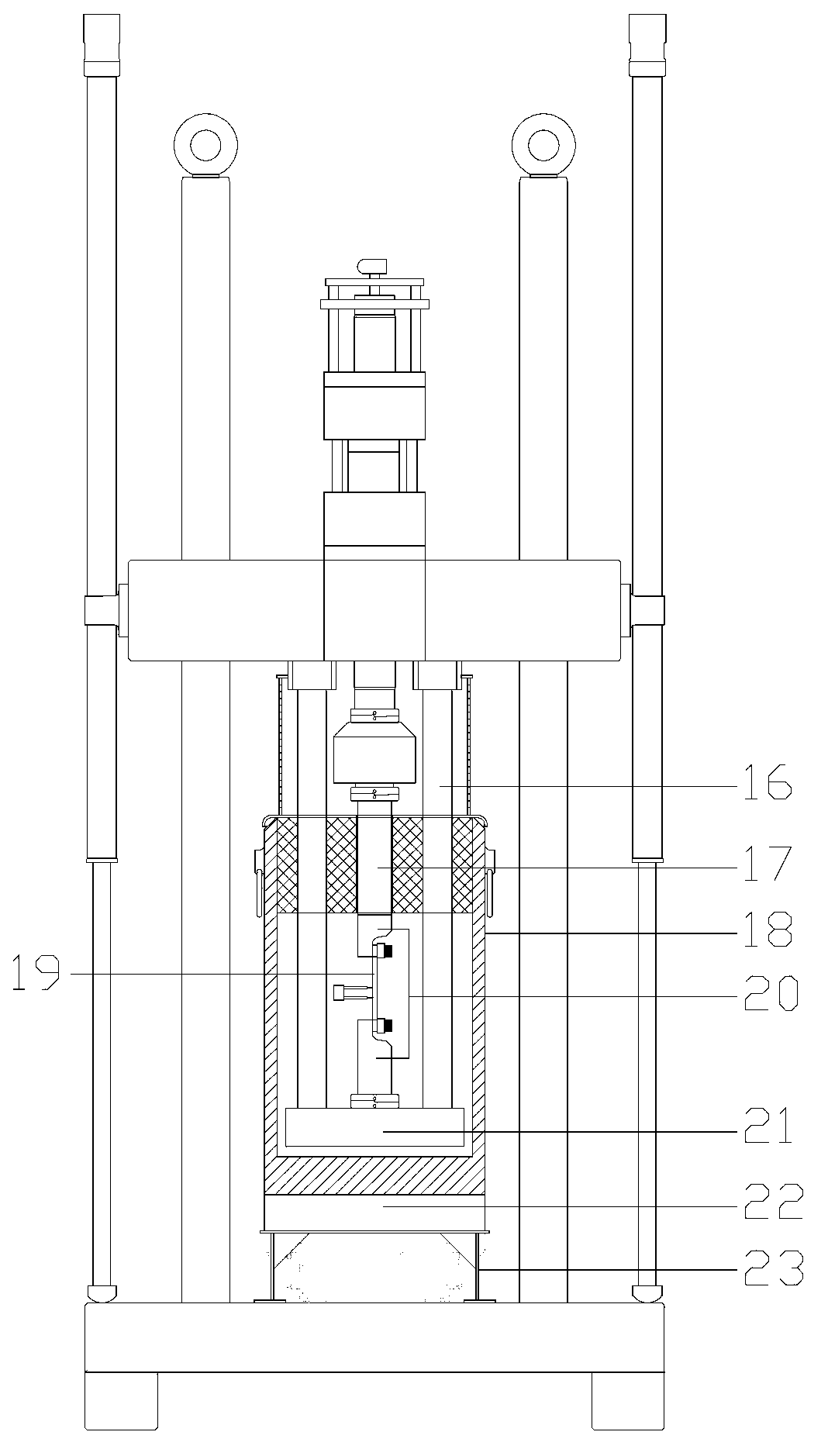

[0026] The device can be divided into a testing machine main body, a testing machine control system, a low temperature constant temperature system and a data detection system. The main body of the testing machine includes a double-column frame and a hydraulic source. The hydraulic source provides power for the movement of the beam 4 of the testing machine and the work of the actuator 3. The frame is a platform for the test and is equipped with a low-temperature constant temperature system. There are two sets of cryogenic and constant temperature systems, which can be switched to each other, namely the liquid nitrogen vaporization refrigeration system and the liquid nitrogen direct refrigeration system.

[0027] The double-column frame includes two columns 2 fixedly arranged on the base 11, and the beam 4 equipped with the actuator 3 is sleeved on the two columns 2 through two through holes; the two ends of the beam 4 are respectively fixed on the vertical On the lifting cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com