Shutoff valve with large drift diameter

A shut-off valve and large-diameter technology, applied in the direction of diaphragm valves, valve devices, pipes/pipe joints/fittings, etc., can solve the problems of difficult opening and closing of valves, unsuitable for frequent switching actions, and high cost of valves, so as to achieve no one-way Fluidity requirements, easy automatic control, labor-saving and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

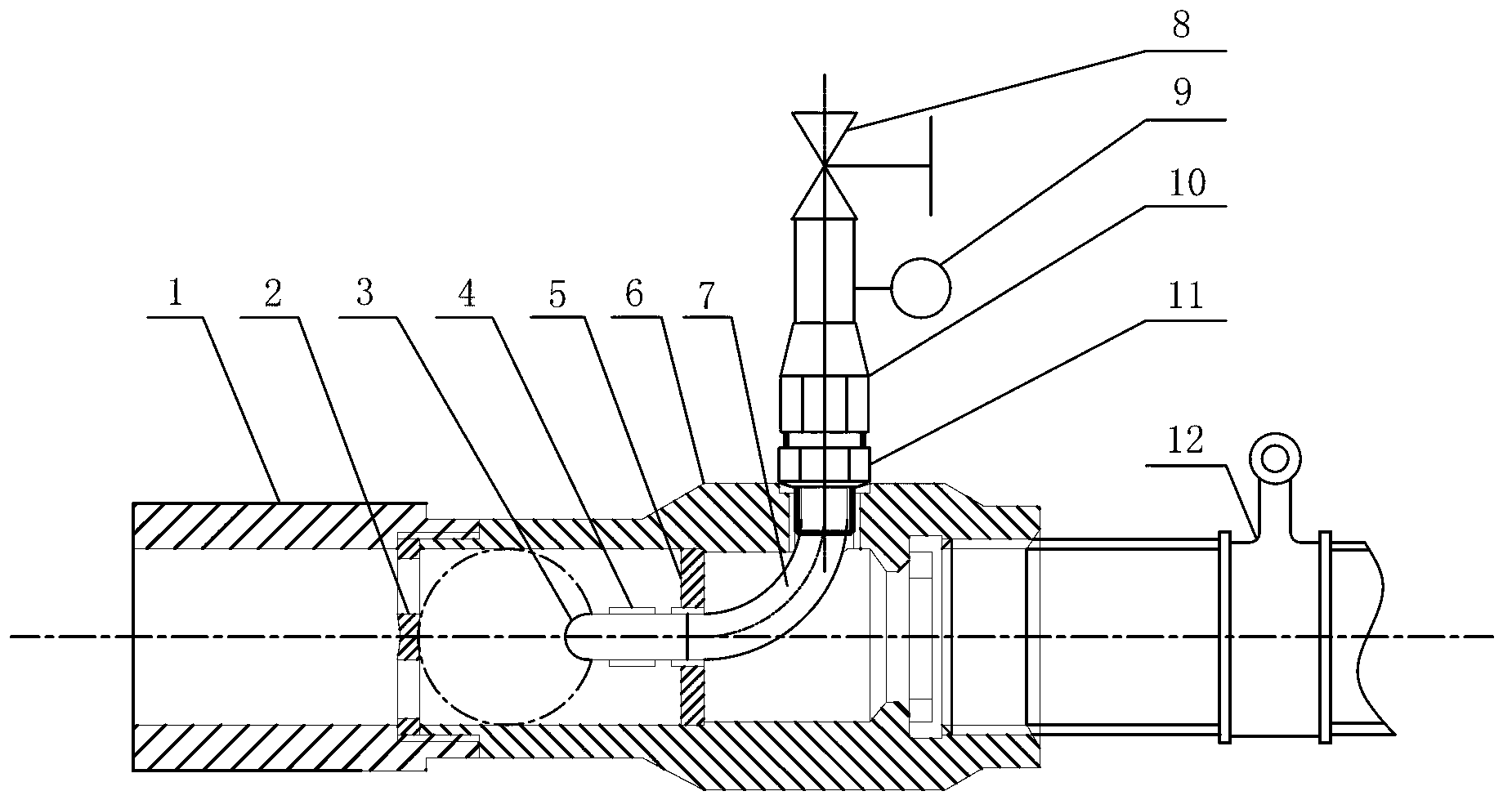

[0026] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

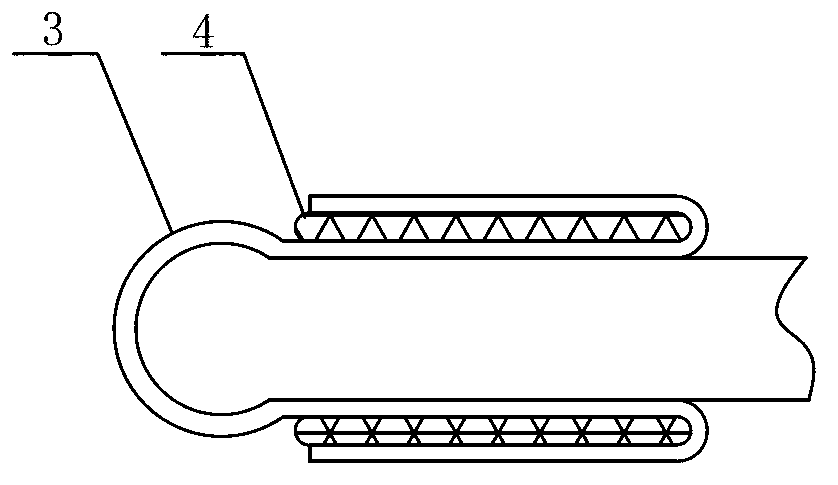

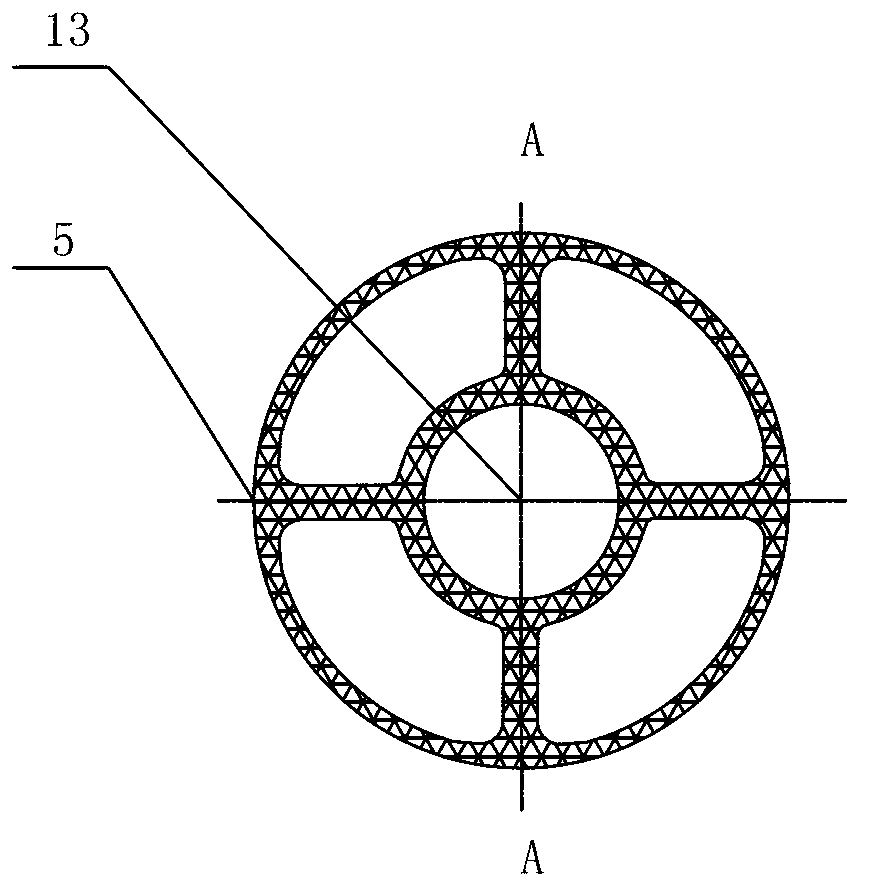

[0027] Such as Figure 1~6 As shown: the large-diameter stop valve of the present invention includes a valve body, a balloon 3 and a gas pipe 8. The valve body is formed by screwing the main valve body 6 and the valve cover 1. The valve body is provided with a retaining ring 2 and a support ring 5, the support ring 5 is fixed in the main valve body 6, and the retaining ring 2 is set between the main valve body 6 and the valve cover 1 (such as Figure 5 and Figure 6 As shown: the center of the baffle ring 2 is set as a spherical surface, and the cut-off function of the balloon 3 is supported on the baffle ring 2 after it is inflated). 6, located between the stop ring 2 and the support ring 5 (such as figure 2 As shown: the balloon 3 is fastened on the trachea 7 through the fixing sleeve 4), and one end of the trachea 7 passes through the central hole 13 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com