Antisludging test kettle

A test kettle, scale inhibition technology, applied in chemical/physical/physical chemical process, chemical instrument and method, chemical/physical process, etc., to achieve the effect of long service life and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

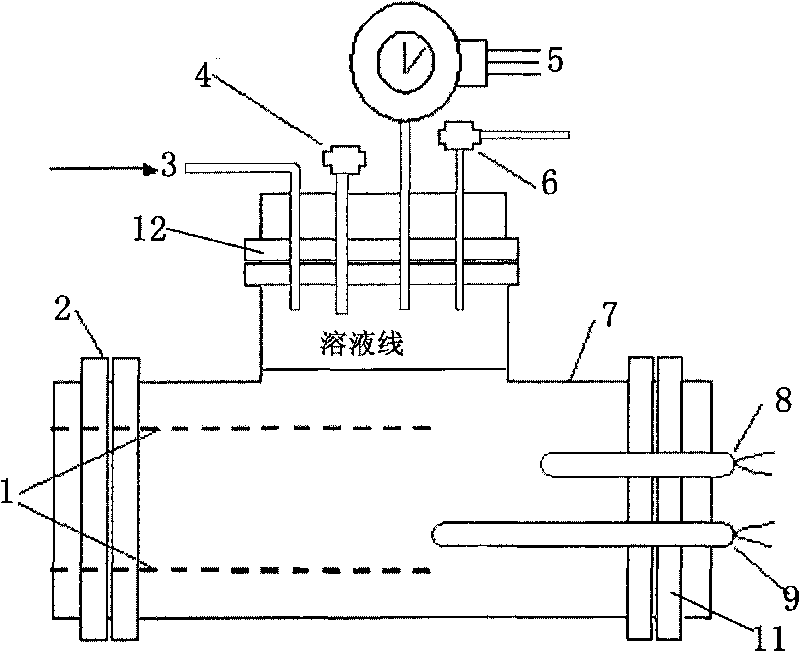

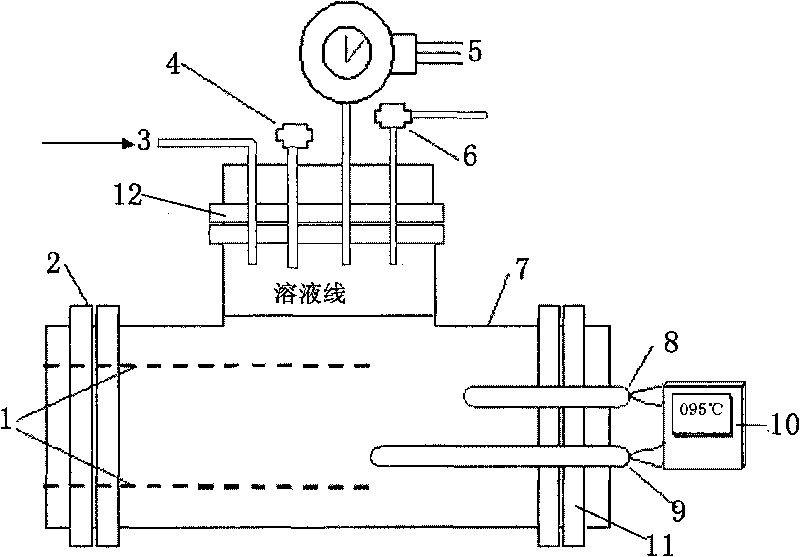

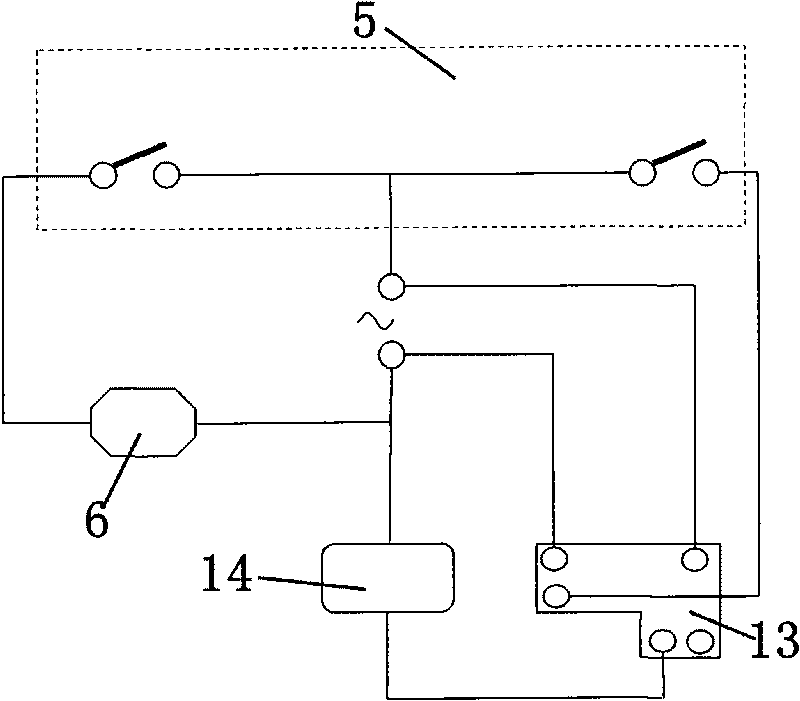

[0018] Example: such as figure 1 As shown, it includes an inverted T-shaped three-way main body 7, an end cover flange, a temperature control device and a pressure control device. End cover flanges are arranged at the three openings of the three-way main body, and the third end cover at the top A pressure control device is provided at the flange 12, a temperature control device is provided at the second end cover flange 11 on one side, and the first end cover flange 2 on the other side is an inspection and maintenance work surface.

[0019] Such as figure 1 As shown, the main body 7 of this example adopts the tee of the PPR pipe material, which is an inverted T shape. The end cover flange in this example includes two neck flat welding flanges with the same structure, which are connected by bolts, one of which is formed by welding a circular plate on the inner hole of the flange, and the neck end without the circular plate flange is connected to the main body of the tee 7Thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com