Method for constructing inclined shaft by applying TBM (Tunnel Boring Machine) with earth pressure balancing function

An earth pressure balance and inclined well technology, which is applied in the field of TBM construction in the construction of inclined wells with large slopes and high buried depths, can solve problems such as many construction difficulties, variable strata, and technical complexity, and achieve reduced construction risks, short construction periods, and Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

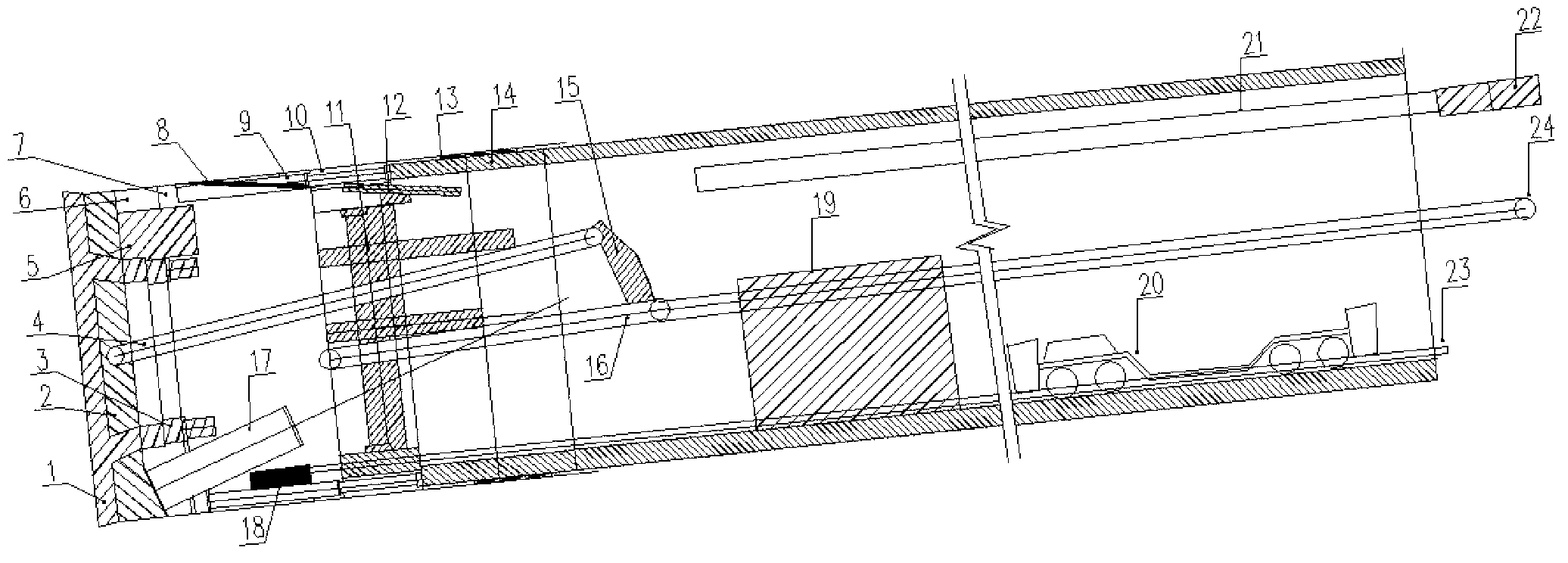

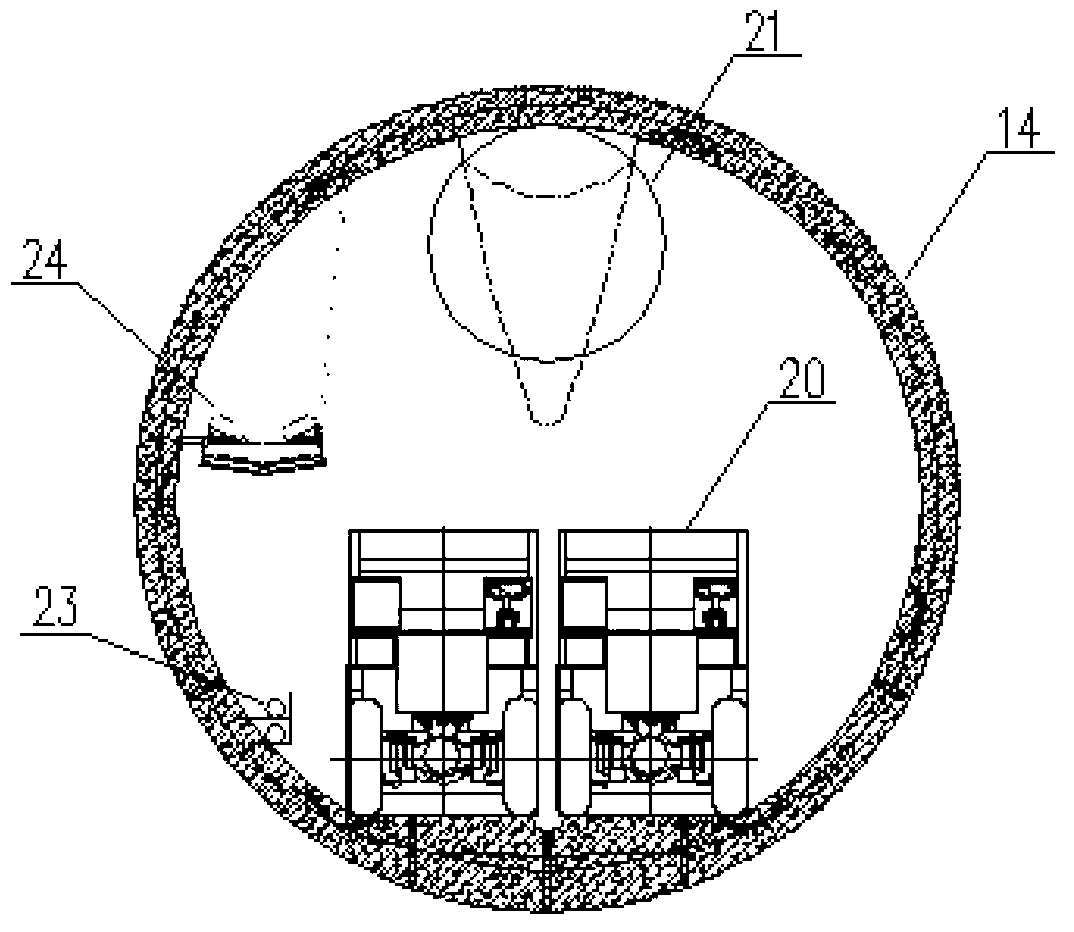

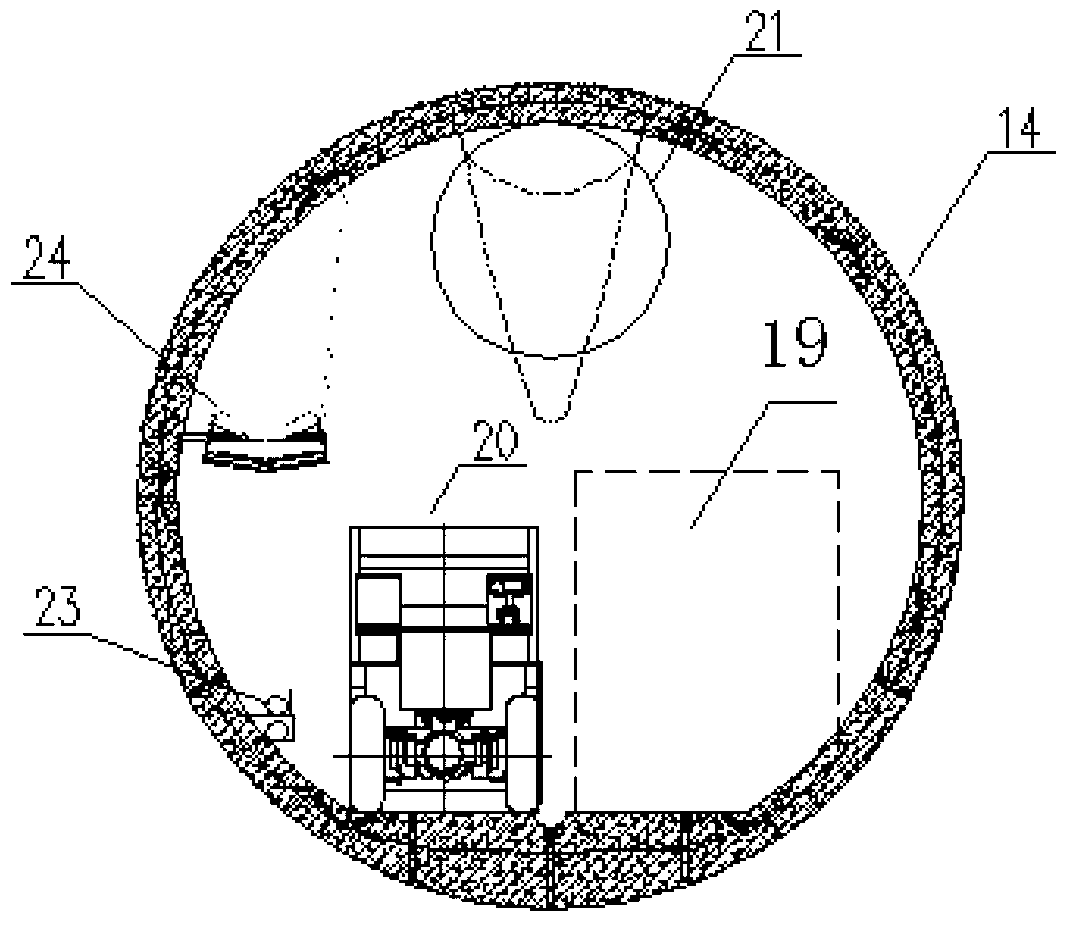

[0025] A method of using TBM with earth pressure balance function to construct inclined shaft, suitable for figure 1 The construction of the inclined shaft with a slope of 6°, a buried depth of 660m and a length of 6134m, the specific implementation process includes:

[0026] 1. Before the TBM tunneling construction, the advanced geological drilling rig 12 performs advanced geological prediction construction of the formation in front of the TBM equipment.

[0027] 2. In the process of TBM tunneling construction, using the eccentric design of the inclined shaft TBM cutter head 1, the center of the TBM cutter head 1 is designed to be 10mm higher than the center of the TBM shell, combined with the conventional method of TBM attitude control, and the automatic guidance equipped on the TBM is used System, real-time observation of TBM attitude, timely adjustment of construction plan, and control of TBM tunneling attitude.

[0028] 3. Do well the auxiliary construction technology of TBM inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com