Three-dimensional enhanced heat-preserving decorative integrated composite board

A composite board, three-dimensional technology, applied in cladding/lining, construction, building construction, etc., can solve problems such as easy cracking, fragility, and low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings.

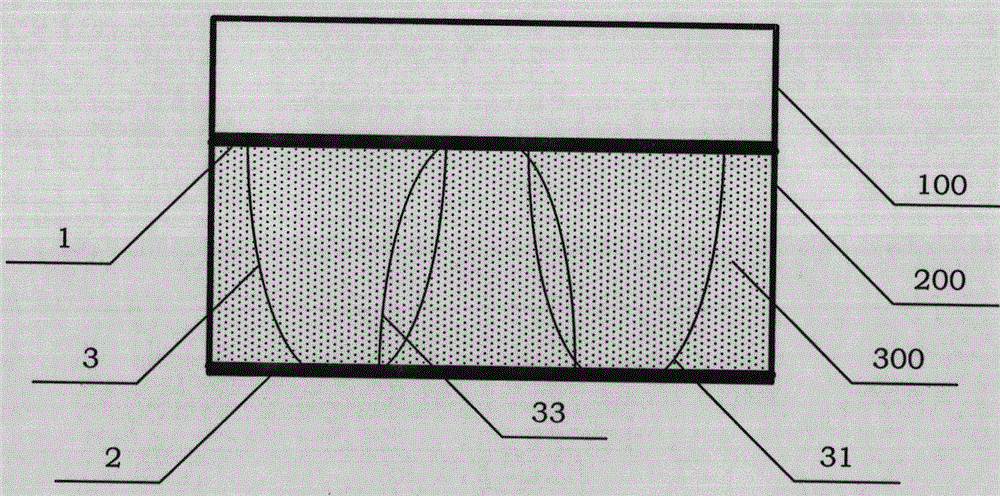

[0051] see figure 1 As shown, a three-dimensional reinforced thermal insulation and decorative composite panel of the present invention includes a decorative layer 100, a three-dimensional grid fabric layer 200 and a filler 300, and the filler 300 is filled in the three-dimensional grid fabric layer 200 , the decorative layer 100 is placed above the three-dimensional grid fabric layer 200 .

[0052] The decorative layer 100 is an aluminum board, a stone board or a calcium carbonate board; specifically, the stone board can be an imitation marble board, an imitation granite board, or an imitation stone paint board.

[0053] The filler 300 is mainly made of cement, bentonite, glass microspheres, etc., which will not burn at high temperature and will not release toxic chlorine. Specifically, the filler 300 is composed of 50-85 parts by weight of cement, 5-20 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com