Anti-seismic, weather-proof and high-strength YS700MPa hot-rolled reinforced bar

A high-strength, steel-reinforced technology, applied in the field of new steel materials, can solve the problem of failure to reach the strength-to-yield ratio of steel bars in seismic-resistant building structures, and achieve the effects of preventing oxidation and corrosion, improving weather resistance, and good seismic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] 1 Semi-industrial trial production

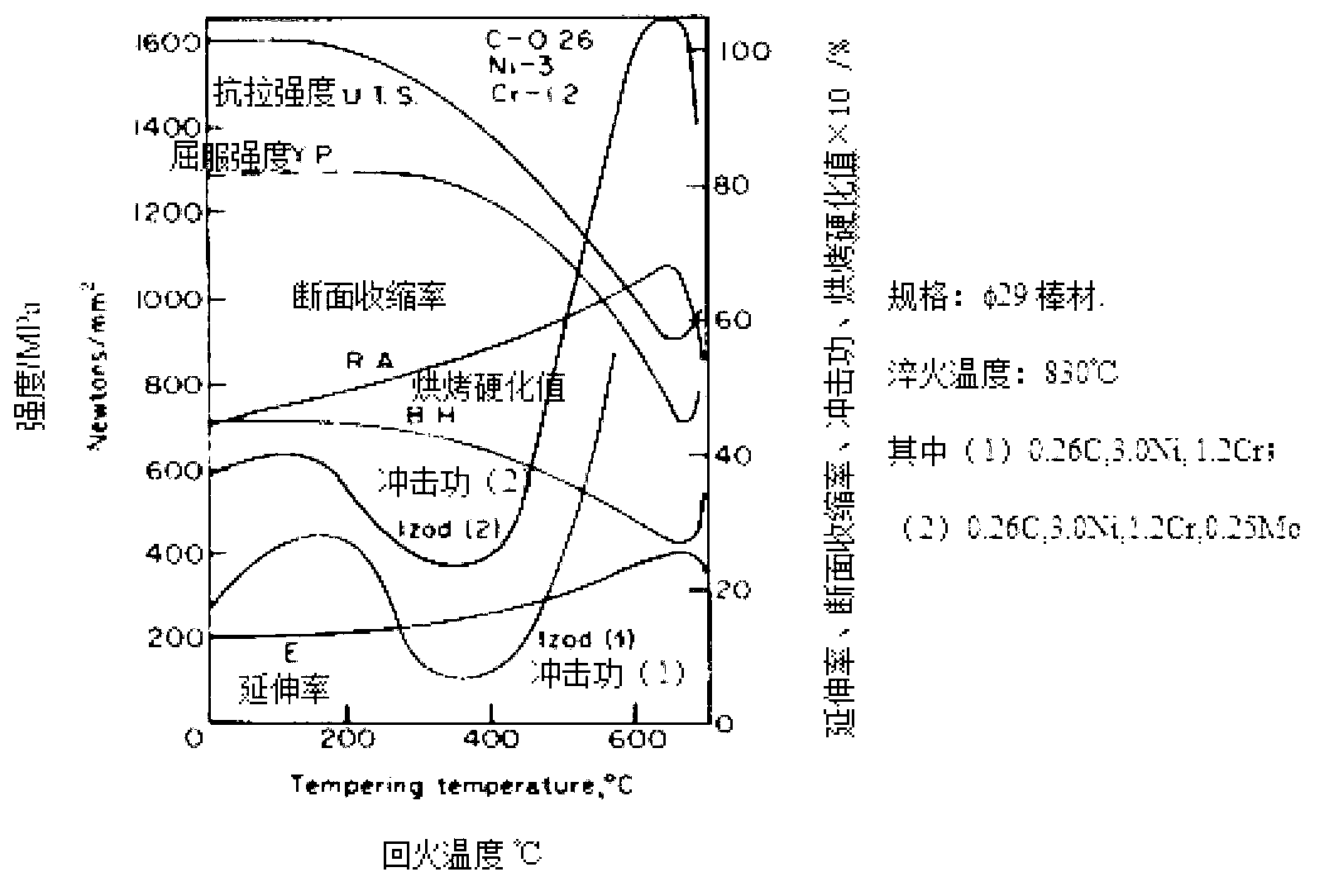

[0095] The semi-industrial trial production of high-strength HRB700SW grade hot-rolled steel bars was carried out in a high-frequency vacuum furnace and a hot continuous rolling mill (28 stands). The test results show that the controlled rolling and controlled cooling of low-nickel-chromium steel can not only make hot-rolled steel bars meet the requirements of yield strength YS700MPa, but also have a very low yield ratio (YS / TS=0.61-0.63 or very high The strength-to-yield ratio TS / YS=1.560-1.64) and good seismic performance are significantly better than the performance index requirements of Japanese and Chinese standards for seismic steel bars, and the yield ratio YS / TS≤0.80 or the strength-to-yield ratio TS / YS≥1.25 .

[0096] Table 5 Chemical composition of HRB700SW grade hot-rolled steel bar in semi-industrial test (nickel-chromium content is the middle limit of the composition)

[0097]

[0098] Table 6 Mechanical properties ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com