Scrap steel bucket loader

A technology for a loader and scrap steel, which is applied in the directions of manufacturing converters and improving process efficiency, can solve the problems of low hopper operation efficiency, less scrap loading, affecting smelting costs, etc. Steel smelting cost and the effect of improving the efficiency of loading operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

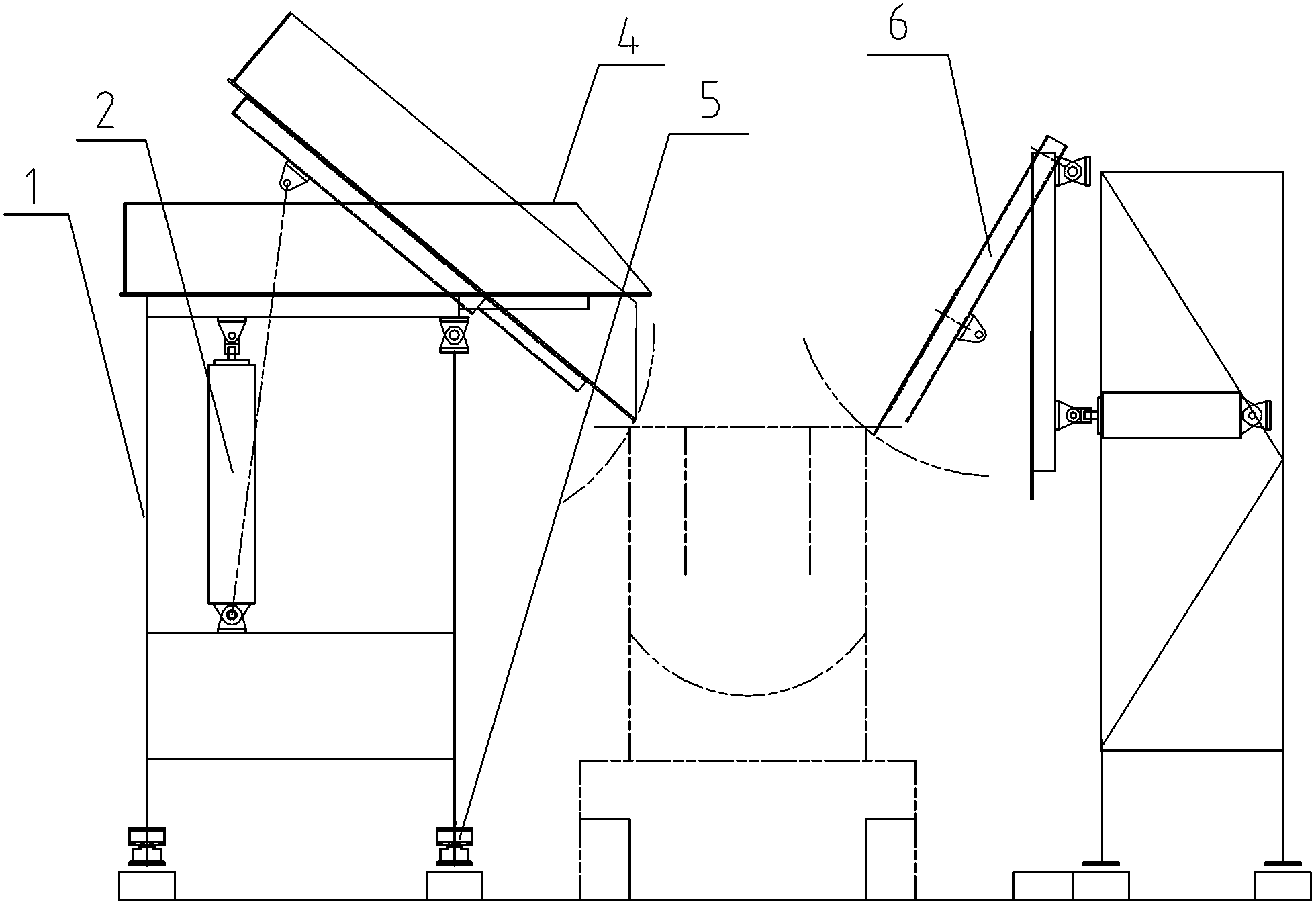

[0012] The scrap steel bucket loading machine provided in this embodiment includes a scrap steel receiving box 4, and a frame 1 is installed under the scrap steel receiving box, wherein the height of the frame is designed and manufactured according to the height of the scrap steel hopper and the tractor. At the same time, one end of the scrap steel receiving box is movably connected to the frame, and the other end is connected to the frame through a hydraulic cylinder 2. In this embodiment, the hydraulic cylinder is a two-way hydraulic cylinder with a large stroke. At the same time, the hydraulic cylinder is also connected with a set of hydraulic control devices. The hydraulic control device sequentially includes a hydraulic oil tank, a hydraulic oil pump, and an electromagnetic reversing valve, wherein the electromagnetic reversing valve is connected to the hydraulic cylinder through a high-pressure hose. The four corners at the bottom of the frame are equipped with weighing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com