Improved gas furnace manhole plug and gas furnace adopting the improved gas furnace manhole plug

A technology of gas furnace and hole plugging, which is applied in the field of gas furnace, and can solve the problems of affecting the operation of the furnace, time-consuming and laborious disassembly and assembly, and heavy weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

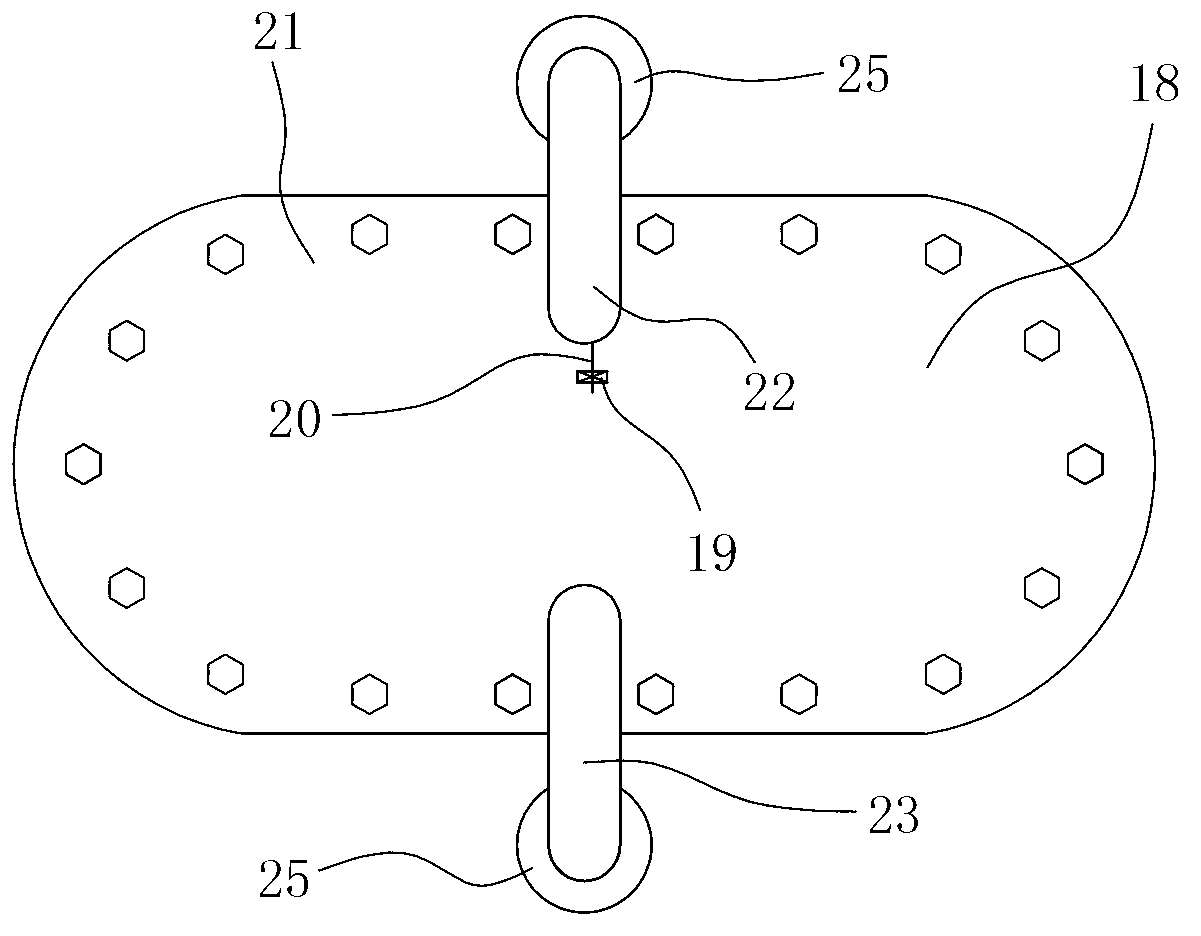

[0012] The technology will be further described below in conjunction with the accompanying drawings.

[0013] The gas furnace of the manhole plug in this embodiment includes a furnace body 1, a manhole plug 2, a water jacket 3, a furnace skirt 4, a grate 5, an ash basin 6, a water seal short pipe 7, a water seal 8 and an inlet The air duct 9, the water jacket 3 are placed on the furnace body 1, the furnace skirt 4 is arranged under the furnace body 1, the furnace grate 5 is placed in the ash basin 6, and the ash basin 6 is filled with water sealing water, and the furnace grate 5 The bottom is provided with a short water seal pipe 7, the furnace skirt 4 is inserted into the water seal water of the ash basin 6, the air inlet pipe 9 is drawn out from the short water seal pipe 7, and a water seal 8 is provided at the outlet of the short water seal pipe 7, and the water seal The short pipe 7 is inserted into the water seal 8, and a water jacket 3 is provided at the bottom of the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com