Supramolecular intercalated structure polymer antioxidant

A molecular structure and polymer technology, applied in the field of layered composite metal hydroxides, can solve the problems of easy migration, anti-thermal and oxygen aging effects, excessive LDH, high ash content, etc., to solve the problem of easy migration to the surface, preparation method Simple, enhanced thermal stability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

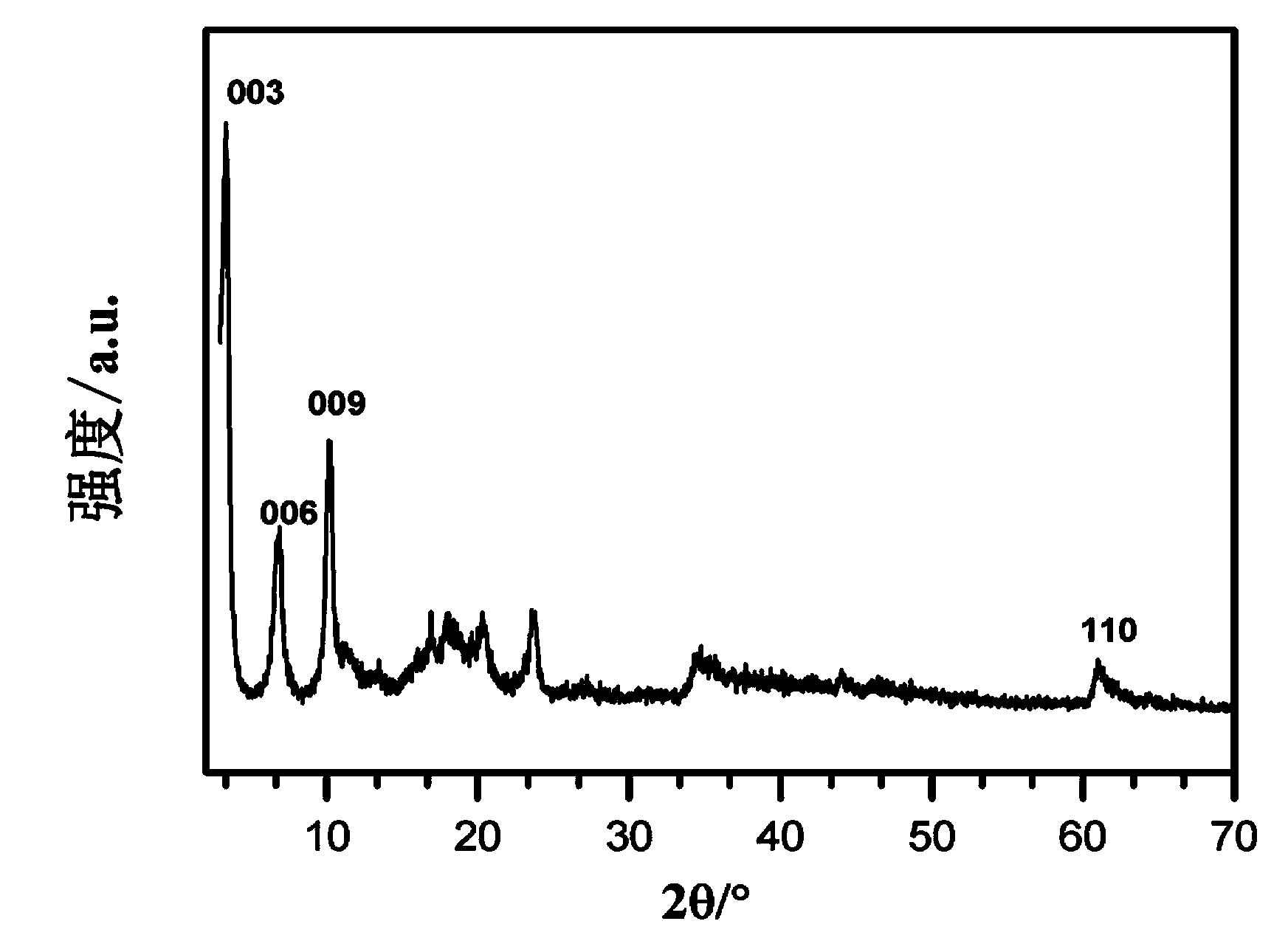

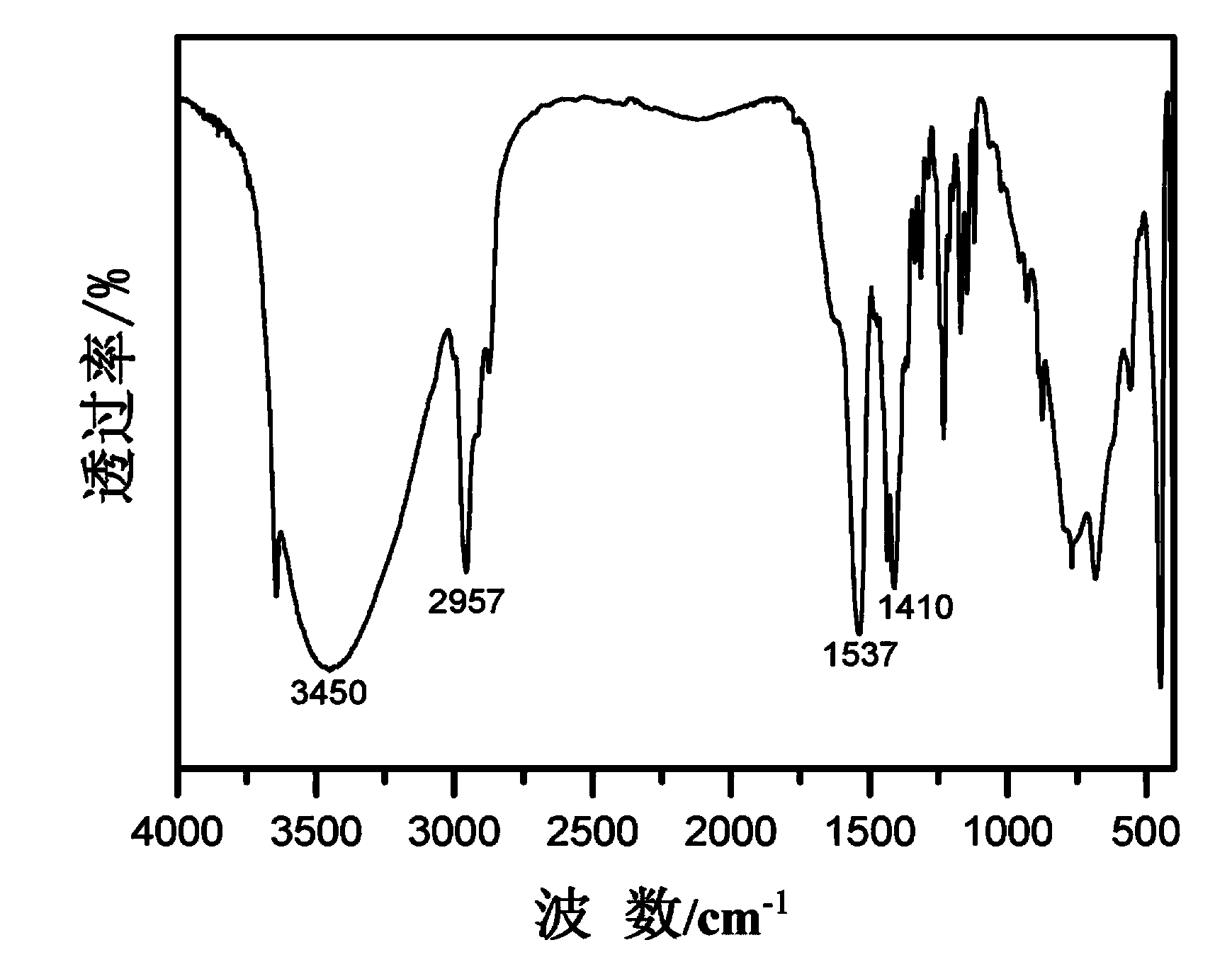

[0040] Embodiment 1: Co-precipitation method prepares supramolecular structure polymer antioxidant

[0041] Step A: take by weighing 2.3076g (10mmol) Mg (NO 3 ) 2 ·6H 2 O, 1.688g (5mmol) Al(NO 3 ) 3 9H 2 O, dissolved in 60mL to remove CO 2 mixed salt solution in deionized water.

[0042] Step B: Weigh 1.44g NaOH and dissolve in 180mL to remove CO 2 Alkaline solution in deionized water.

[0043] Step C: Weigh 2.502g of β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid and add to 100mL to remove CO 2 of deionized water.

[0044] Step D: Add the solution prepared in step C to the solution prepared in step A, add the solution prepared in step B dropwise to the mixed solution of A and C under nitrogen protection and stirring, and complete the dropwise addition within 30 minutes. Control the pH = 9. Then react at room temperature and under the protection of nitrogen for 24 hours, after 6 cycles of filtration and washing, the pH value of the mother liquor is finally neut...

Embodiment 2

[0045] Embodiment 2: Ion exchange method prepares supramolecular structure polymer antioxidant

[0046] Step A: Weigh 1.233g LDH-NO 3 Dissolve in 60mL to remove CO 2 of deionized water.

[0047] Step B: Weigh 1.44g NaOH and dissolve in 180mL to remove CO 2 Alkaline solution in deionized water.

[0048] Step C: Weigh 2.12g of β-(3-tert-butyl-4-hydroxy-5-methylphenyl)propionic acid and add to 100mL to remove CO 2 of deionized water.

[0049] Step D: Add the solution prepared in step B to the solution prepared in step C until dissolved.

[0050] Step E: Add the solution prepared in step D dropwise to solution A under nitrogen protection and stirring, complete the dropwise addition within 30 minutes, control pH = 9, then react at room temperature and nitrogen protection for 24 hours, and filter and wash 6 times Treat until the pH value of the mother liquor is neutral, and vacuum-dry the filter cake for 24 hours to obtain a white supramolecular structure polymer antioxidant p...

Embodiment 3

[0051] Embodiment 3: Preparation of supramolecular structure polymer antioxidant by roasting recovery method

[0052] Step A: Weigh 0.273g LDO and dissolve in 30mL to remove CO 2 of deionized water.

[0053] Step B: Weigh 0.28g NaOH and dissolve in 7mL to remove CO 2 Alkaline solution in deionized water.

[0054] Step C: Weigh 2.502g of 3,5-di-tert-butyl-4-hydroxybenzoic acid and add 50mL to remove CO 2 of deionized water.

[0055] Step D: Add the solution prepared in step B to the solution prepared in step C until dissolved.

[0056] Step E: Add the solution prepared in step D dropwise to solution A under nitrogen protection and stirring, complete the dropwise addition within 30 minutes, control pH = 10, then react at room temperature and nitrogen protection for 24 hours, and filter and wash 6 times Treat until the pH value of the mother liquor is neutral, and vacuum-dry the filter cake for 24 hours to obtain a white supramolecular structure polymer antioxidant powder AO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com