Application of brine to boiler softened water in stead of industrial salts

A technology for industrial salt and softened water, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, ion exchange water/sewage treatment, etc., can solve the waste of industrial salt and salt solution, and the high cost of industrial salt use , affecting the normal operation of equipment and other problems, to achieve the effect of improving processing capacity, stable equipment performance, and convenient operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

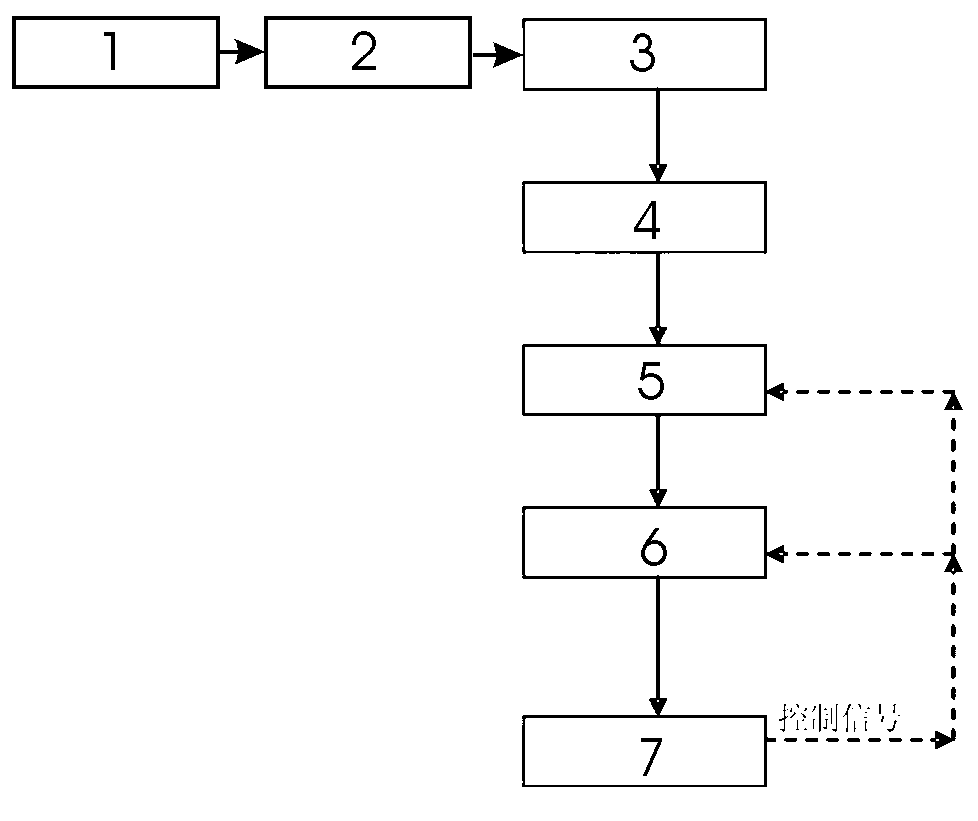

[0011] Now refer to the attached figure 1 , illustrate as follows in conjunction with embodiment: the brine of the present invention replaces the application of industrial salt on boiler demineralized water, comprises sodium hydroxide 1, brine storage tank A2, precision filter 3, brine storage tank B4, electromagnetic valve 5, conveying Pump 6 and ion exchanger 7. Sodium hydroxide 1 is connected to brine storage tank A2, brine storage tank A2 is connected to precision filter 3, precision filter 3 is connected to brine storage tank B4, brine storage tank B4 is connected downward to solenoid valve 5, and solenoid valve 5 is downward Connected to transfer pump 6 which is connected down to ion exchanger 7 . The control signal sent by the ion exchanger 7 is connected to the solenoid valve 5 while being connected to the delivery pump 6 , that is to say, the control signal sent by the ion exchanger 7 is connected to the delivery pump 6 and the solenoid valve 5 at the same time. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com