Dual-station cutting machine tool

A cutting machine tool and double-station technology, which is applied in metal processing and other directions, can solve the problems of low production efficiency, low material utilization rate, and low product qualification rate, and achieve the effects of increased production efficiency, high value, and reduced waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

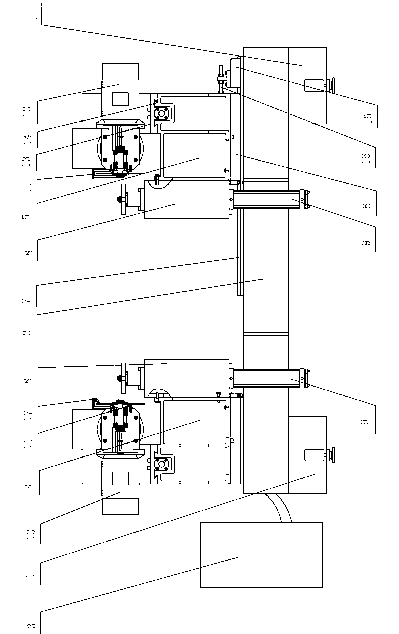

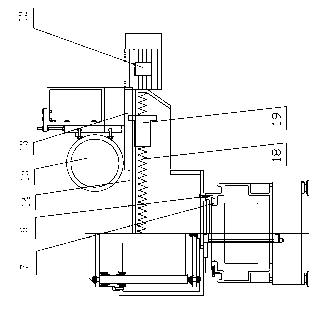

[0012] Such as figure 1 , figure 2 As shown, a double-station cutting machine tool includes a base 1, a bed 2 fixed on the base 1, and an electrical control cabinet 3. A left box 4 is fixed on the left side of the bed 2, and a right box is arranged on the right side. 5. The right box body 5 is fixed on the first slide plate 6, and the first slide plate 6 is movable and fixed on the first guide rail 7 parallel to the bed 2 through the chute; the left box body 4 and the right box body 5 are respectively Second guide rail 14 is housed, and lead screw 18 is fixed in the middle of second guide rail 14, and second slide plate 13 is installed on the top of second guide rail 14, and lead screw nut 19 is fixed on the bottom of second slide plate 13, left and right casing rear part also The feed motor 12 that links to each other with leading screw is installed; Also be fixed with universal clamping device 8 on described left box body 4, right box body 5, the below of universal cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com