Manufacturing method of radial fuzzy neural network generalized inverse controller of bearingless asynchronous motor

A technology of fuzzy neural network and asynchronous motor, which is applied in the direction of motor generator control, AC motor control, electronic commutation motor control, etc., and can solve application difficulties, type and structure selection dependence, pseudo-linear system open-loop instability, etc. problem, to achieve the effect of strong fuzzy reasoning ability, improving learning ability, and overcoming local minimum points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

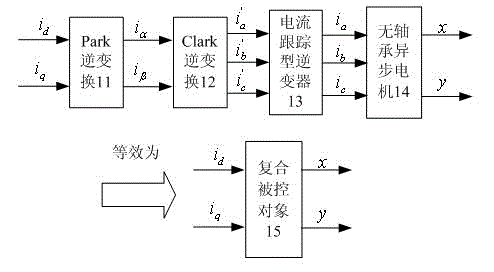

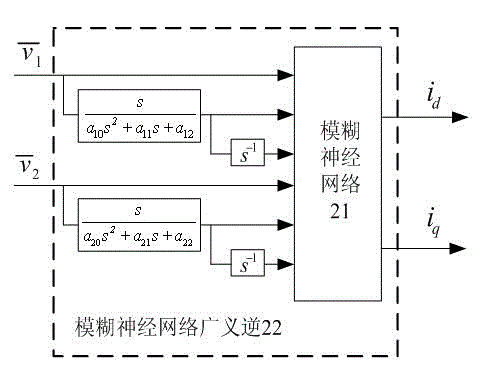

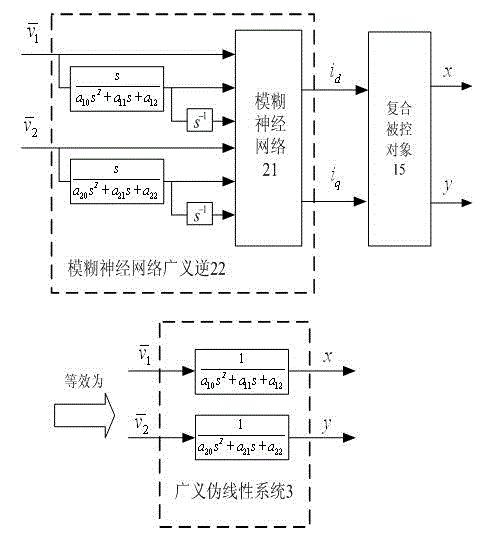

[0018] The embodiment of the present invention is as follows: first, the complex controlled object is composed of Park inverse transform, Clark inverse transform, current tracking inverter, and the radial position of the controlled bearingless asynchronous motor, and the compound controlled object is equivalent to two A 4th-order differential equation model in a phase-rotating coordinate system, the relative order of the system vectors is {2,2}. A fuzzy neural network (5-layer network) with 6 input nodes and 2 output nodes and 4 linear links are used to form the generalized inverse of fuzzy neural network of a compound controlled object with 2 input nodes and 2 output nodes. And by adjusting each parameter and weight of the fuzzy neural network, the generalized inverse of the fuzzy neural network realizes the function of the generalized inverse system of the compound controlled object. Then the generalized inverse of the fuzzy neural network is placed before the compound contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com