Determination method of hydrazinium mononitrate and hydroxylamine nitrate

A technology of hydroxylamine nitrate and determination method, which is applied in the direction of measuring device, color/spectral characteristic measurement, and material analysis through optical means, which can solve the problems of undisclosed operation steps and process parameters, and achieve the effect of simple analysis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

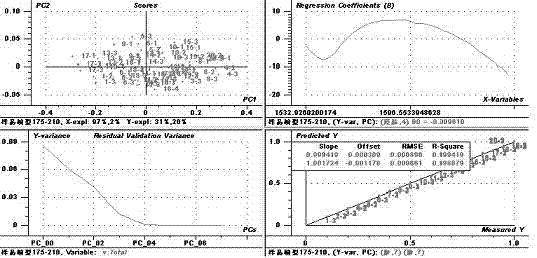

Image

Examples

Embodiment 1

[0019] (a) Preparation of modeling sample set:

[0020] A series of 20 modeling samples were prepared for specific analysis objects, as shown in Table 1. The sample composition includes hydrazine nitrate and hydroxylamine nitrate, and the concentration range is large enough.

[0021] serial number Concentration of hydrazine nitrate / (mol / L) Concentration of hydroxylamine nitrate / (mol / L) 1 0.05 0.20 2 0.10 0.40 3 0.15 0.60 4 0.20 0.80 5 0.25 1.00 6 0.30 0.15 7 0.35 0.35 8 0.40 0.55 9 0.45 0.75 10 0.50 0.95 11 0.55 0.10 12 0.60 0.30 13 0.65 0.50 14 0.70 0.70 15 0.75 0.90 16 0.80 0.05 17 0.85 0.25 18 0.90 0.45 19 0.95 0.65 20 1.00 0.85

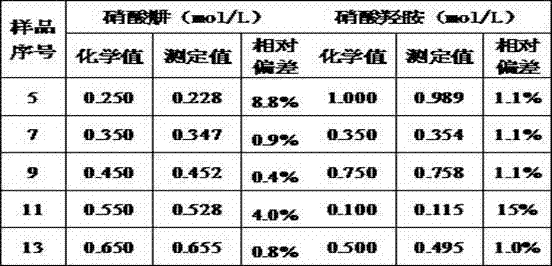

[0022] According to the concentration and spectral characteristics of the sample components, the samples were divided into a calibration set and a verification set, and Nos. 5, 7, 9, 11, and 13 were selected as ...

Embodiment 2

[0035] Sample determination result in table 4 embodiment 2

[0036]

[0037] It can be seen from the table that the relative deviation of the measurement results with air as a reference is larger than that with water as a reference.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com