Method for establishing and determining slab caster-overhauling reference coordinate system

A slab continuous casting machine and coordinate system technology, which is applied in the field of measurement and control, achieves the effects of establishing a reasonable coordinate system, improving detection efficiency, and simplifying the data analysis process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0028] (1) Construction preparation

[0029] After the fan section is removed, first prepare a slab with a thickness of 150-200mm and place it on the middle beam of the support frame of the horizontal fan section for erecting the instrument;

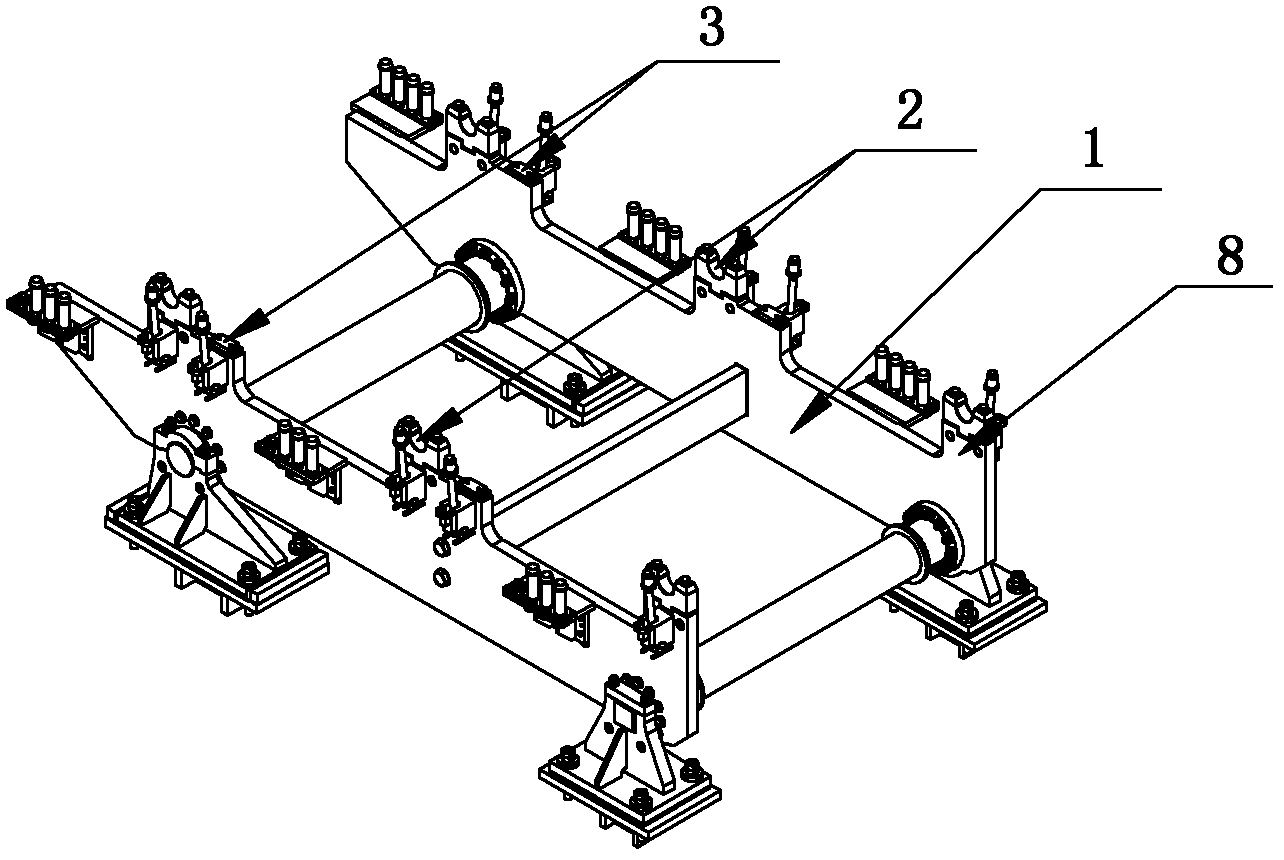

[0030] Then the surveyors set up the reference points of the coordinate system. The surveyors observe according to the site conditions, determine the welding position of the coordinate reference points and mark them, remove the walking table that hinders the line of sight, and carry out welding of the coordinate reference points. The position of the coordinate reference points must be The layout is reasonable. (See image 3 )

[0031] (2) Acquisition of credible benchmark raw data

[0032] A When the temperature in the measurement area drops below 30°C, first collect the coordinates of the original reference point in the instrument coordinate system.

[0033] B Support the inner wall of the fan-shaped segment under the instrument coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com