Multipurpose in-situ microscale mechanical property tester under scanning electron microscope

A scanning electron microscope, multi-purpose technology, applied in scientific instruments, strength characteristics, instruments, etc., can solve the problems of inability to monitor crack propagation, difficult cyclic loading and unloading tests, slow dynamic frequency response of stepper motors, etc. Control, good dynamic response frequency, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

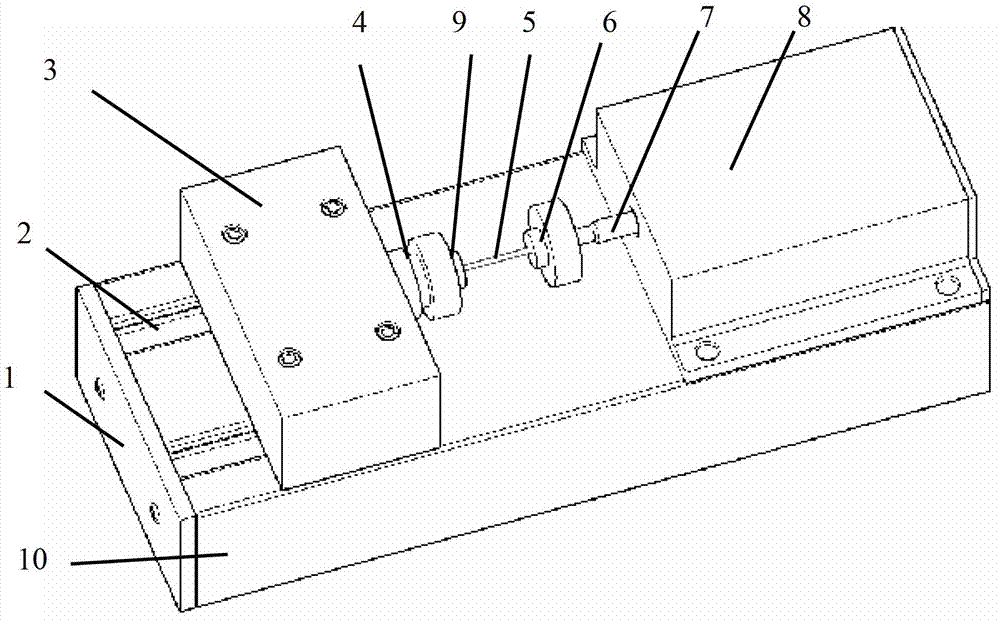

[0036] Aiming at the above problems, the present invention proposes a micro-scale in-situ mechanical property tester driven by a voice coil motor (electromagnetic), used for scanning electron microscope, capable of stretching, compressing, bending and fatigue testing.

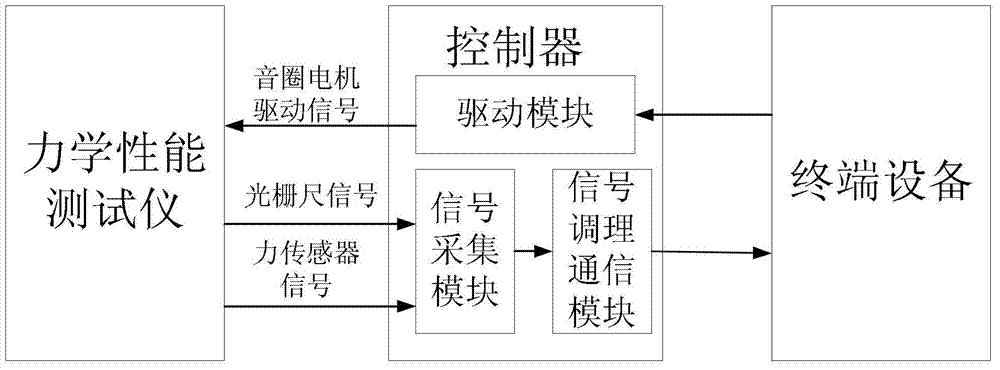

[0037] In the present invention, the driving part of the main body of the tester is driven by a voice coil motor. The basic principle is that the electromagnetic coil is stressed in the magnetic field, and the coil movement is controlled by controlling the current in the coil. This driving method has the advantages of smoothness, no vibration, fast dynamic frequency response, and easy and precise control.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com