Camshaft arrangement structure of multi-functional gas distribution mechanism test stand

A gas distribution mechanism and camshaft technology, which is applied in the testing of machine/structural components, engine testing, valve devices, etc., can solve the problems of long camshaft processing cycle, high cost, and high complexity of test benches, etc., to achieve The effect of shortening the processing cycle, high reuse rate and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

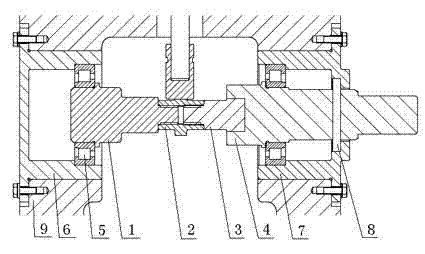

[0027] A camshaft arrangement structure of a multifunctional valve mechanism test bench, mainly including a camshaft support module, a cam module, a transmission module, a transmission coupling shaft, a rolling bearing, a rear thrust bearing sleeve, a front thrust bearing sleeve, a sealing ring, a support Parts such as the box body, among which, the camshaft is composed of the support module, the cam module and the transmission module; the cam module is respectively connected with the support module and the transmission module in the form of precision threads, the tightening torque is constant, and the thread screwing direction needs to be consistent with the The camshafts rotate in the same direction;

[0028] The two rolling bearings that provide support for the camshaft are located at both ends of the camshaft, one at each end; the rear thrust bearing sleeve and the front thrust bearing sleeve that jointly control the axial movement of the camshaft are respectively matched w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap