Hydraulic password door

A coded door and hydraulic technology, which is applied in the direction of coded locks, door leaves, door/window accessories, etc., can solve the problems of easy aging of rubber sealing elements, the door is not suitable for hydraulic code system, and poor reliability, so as to increase the reliability of use Effects related to maintainability, reduced work efficiency, and easy wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

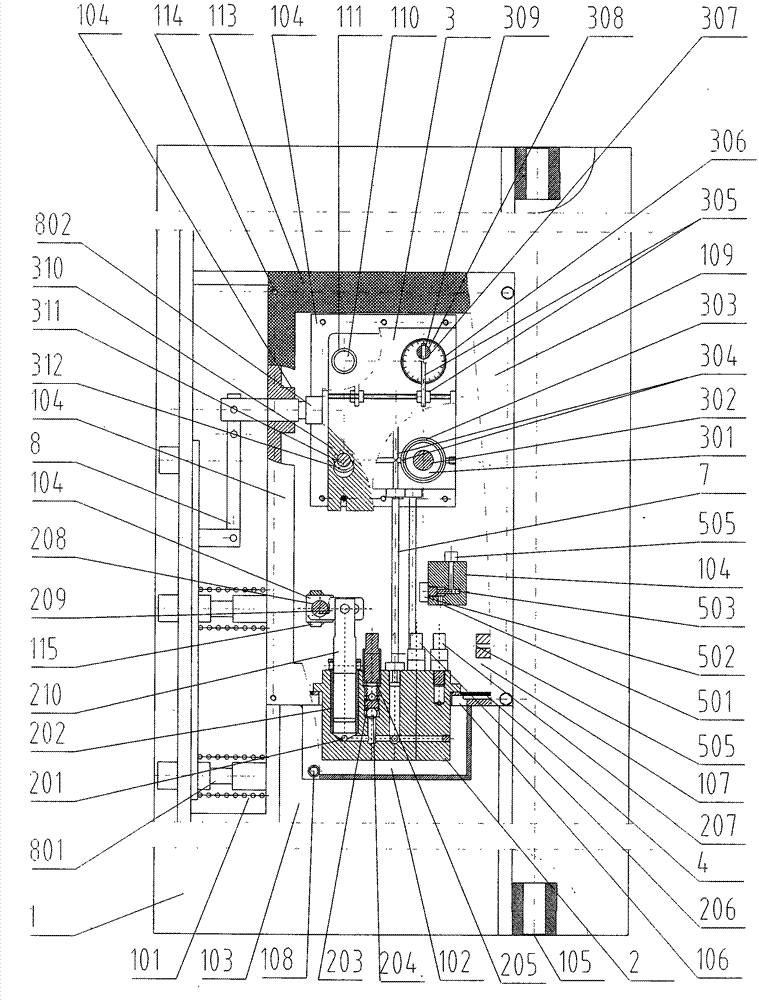

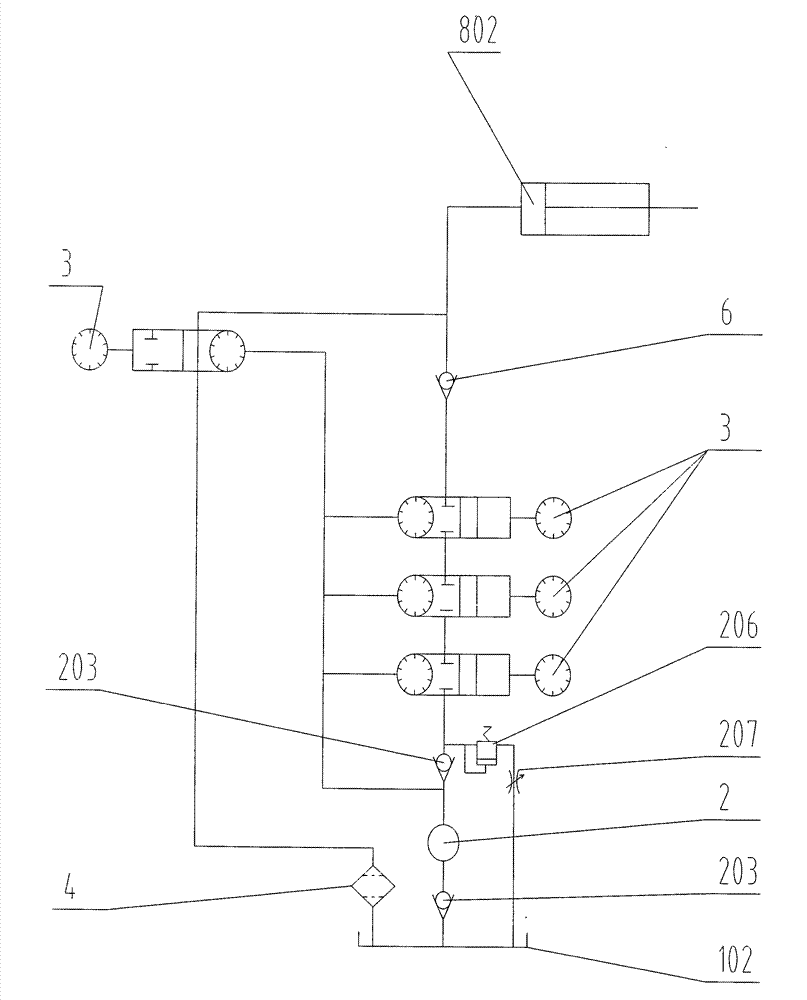

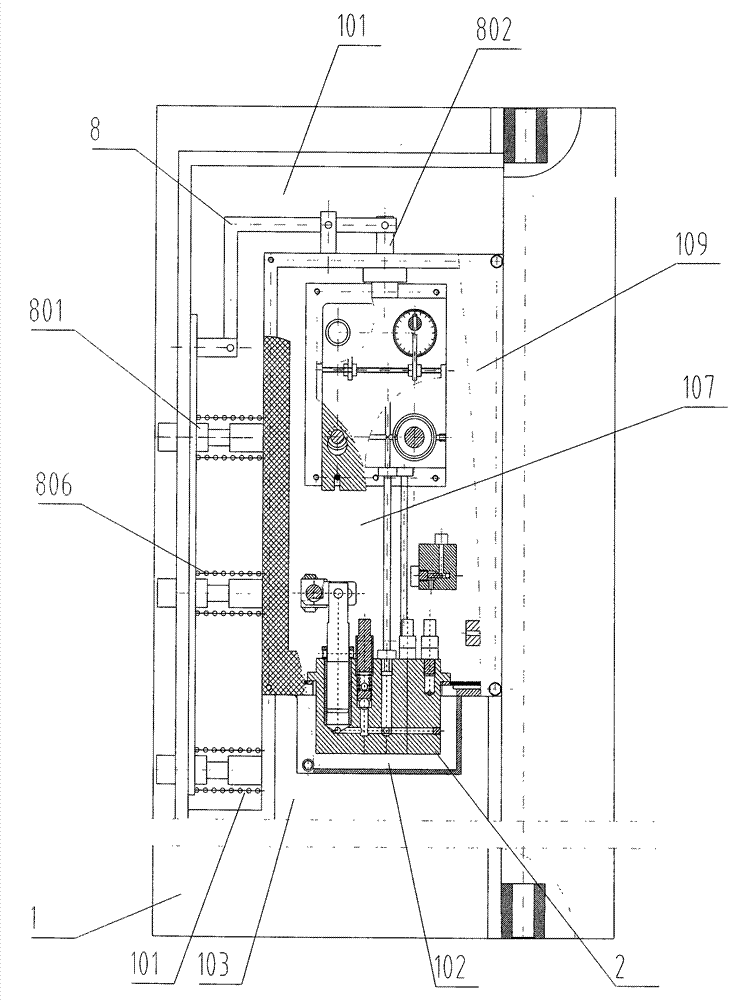

[0052] Attached figure 1 What is shown is one of the embodiments of the present invention, and at the same time, it integrates a variety of optimized structures that we have summarized in the development process over the past few years.

[0053] The door panel 1 has a password working chamber 107; the inner wall of the password working chamber 107 is painted with oil-resistant anti-rust paint (not marked in the figure) to prevent rust; the weather-resistant strip 113 is installed between the door panel 1 and the inner sealing plate 109, which is effective Prevent the working fluid from leaking out between the door panel 1 and the inner sealing plate 109; the filter device 4 is installed on the oil return passage 106 between the password working chamber 107 and the fuel tank 102, and the filter device 4 effectively prevents impurities in the password working chamber 107 from entering Fuel tank 102; the filling hole 503 communicates with the outside of the door panel 1, the filling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com