System and method for generating power with blast-furnace slag washing water and exhaust steam low-temperature waste heat

A blast furnace slag flushing water, low-temperature power generation technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve the problems of increasing the thermal pollution and visual pollution of the chimney with spent steam, incomplete heat recovery of the slag flushing system, waste of waste heat resources, etc. To achieve the effect of reducing thermal pollution and visual pollution, good economic and social benefits, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

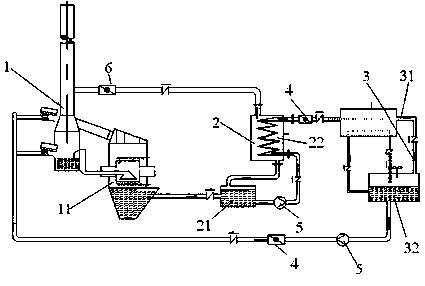

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] see figure 1 , a blast furnace slag flushing water and exhaust steam low-temperature waste heat power generation system, including a blast furnace slag flushing subsystem, a precipitation heat exchange subsystem, and a low-temperature power generation subsystem. The quenching and granulation device 11, the precipitation heat exchange subsystem further includes a sedimentation tank 21 and a heat exchange device 2, the heat exchange device 2 is provided with a waste steam heat recovery device 22, and the high-temperature slag washing water of the blast furnace slag quenching and granulation device 11 The outlet is connected to the sedimentation tank 21, and the outlet of the sedimentation tank 21 is connected to the exhaust steam heat recovery device 22. The exhaust steam of the blast furnace slag quenching and granulation device 11 enters the heat exchange devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com