Alcohol production process

A production process and alcohol technology, applied in microorganisms, biofuels, microorganism-based methods, etc., can solve the problems of different fermentation raw materials and different alcohol production methods, and achieve the effects of mature technology, reduced energy consumption, and high alcohol concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

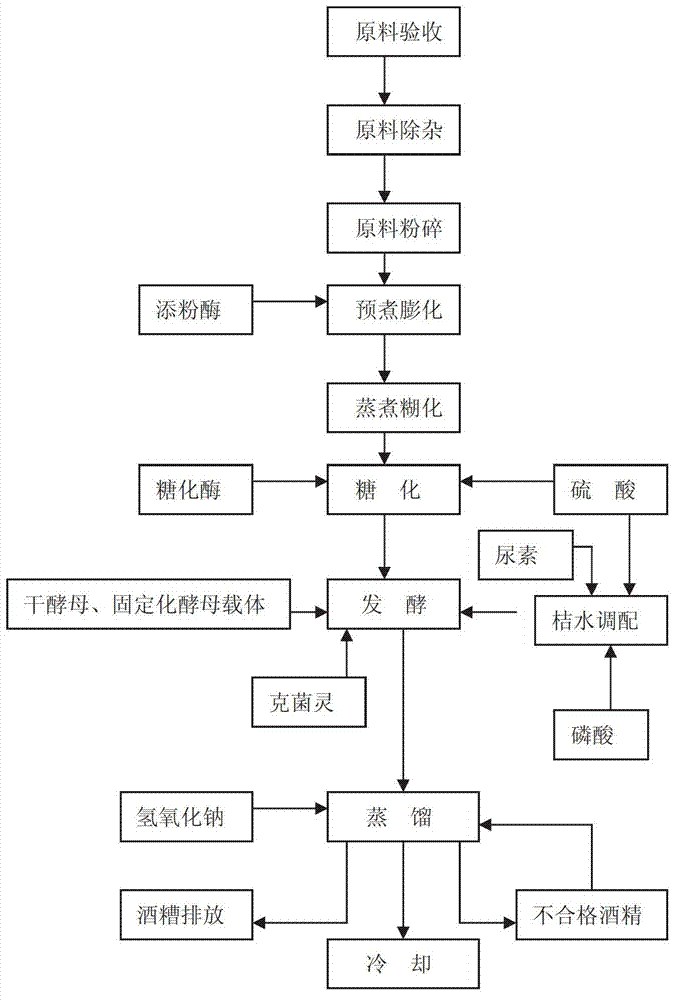

Image

Examples

Embodiment 1

[0024] Embodiment 1, a kind of production technology of alcohol, comprises the steps:

[0025] 1) Acceptance of raw materials: choose potatoes with relatively complete roots, uniform size, and about 30% starch content as raw materials, wash them with water and set aside.

[0026] 2) Impurity removal of raw materials: The raw materials washed with clean water are transported to the impurity remover by a belt conveyor to remove impurities such as sediment, stones and metals in raw potatoes.

[0027] 3) Raw material crushing: After removing impurities, the raw material is weighed and transported to the axial drum type coarse crushing by the belt conveyor for coarse crushing. The coarse crushed material is then sent to the hammer mill for fine crushing to obtain raw material powder.

[0028] 4) Precooking and puffing: the raw material powder is adjusted to a wort concentration of 10g / ml with water at a ratio of 1:3, heated to 50°C with steam under normal pressure, and amylase is a...

Embodiment 2

[0035] 1) Acceptance of raw materials: choose potatoes with relatively complete roots, uniform size, and about 35% starch content as raw materials, wash them with clean water and set aside.

[0036] 2) Impurity removal of raw materials: The raw materials washed with clean water are transported to the impurity remover by a belt conveyor to remove impurities such as sediment, stones and metals in raw potatoes.

[0037] 3) Raw material crushing: After removing impurities, the raw material is weighed and transported to the axial drum type coarse crusher for coarse crushing through the belt conveyor. The coarsely crushed material is then sent to the hammer mill for coarse crushing to obtain raw material powder.

[0038] 4) Precooking and puffing: adjust the raw material powder with water to a wort concentration of 12g / ml at a ratio of 1:3 to the ratio of material to liquid, heat it to 55°C with steam under normal pressure, add amylase, and precook for 25 minutes.

[0039] 5) Cookin...

Embodiment 3

[0045] 1) Acceptance of raw materials: choose potatoes with relatively complete roots, uniform size, and about 40% starch content as raw materials, wash them with clean water and set aside.

[0046] 2) Impurity removal of raw materials: The raw materials washed with clean water are transported to the impurity remover by a belt conveyor to remove impurities such as sediment, stones and metals in raw potatoes.

[0047] 3) Raw material crushing: After removing impurities, the raw material is weighed and transported to the axial drum type coarse crushing by the belt conveyor for coarse crushing. The coarse crushed material is then sent to the hammer mill for fine crushing to obtain raw material powder.

[0048] 4) Precooking and puffing: adjust the raw material powder with water at a ratio of 1:3 to the wort concentration of 14g / ml, heat to 60°C with steam under normal pressure, add amylase, and precook for 25 minutes.

[0049] 5) Cooking and gelatinization: adopt the low-pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com