Functional laminated sheet, and transparent electrically conductive laminated sheet for touch panel and touch panel produced using same

A transparent conductive layer, transparent conductive technology, applied to the conductive layer, application, coating and other directions on the insulating carrier, can solve the problems of poor operability, lack of pressing feeling, cracking, etc. The effect of lightness, toughness and pressing feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

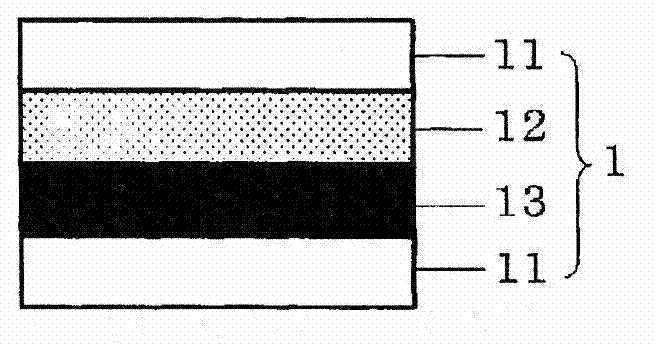

[0068] The functional laminate of the first embodiment has a functional layer in at least one of the plastic film and the plastic film. its specific example Figure 1 to Figure 4 shown. figure 1 and figure 2 Indicates that the plastic film is 2 pieces, image 3 and Figure 4 Indicates the case where there are three plastic films. The position of the functional layer 13 in the laminated body 1 is also different according to the purpose of the functional layer and the method of formation, and can be as follows: figure 1 , image 3 Between the plastic film 11 and the adhesive layer 12 as shown, it is also possible to figure 2 , Figure 4 between the adhesive layers 12 that way. In the functional laminated board of the present embodiment, since the functional layer is present inside the laminate, damage to the functional layer can be prevented and durability can be improved.

[0069] Examples of the functional layer in this embodiment include a layer having a function s...

no. 2 approach

[0089] The functional laminated board of the second embodiment has a functional layer on at least one surface of the outermost plastic film. its example Figure 5 ~ Figure 7 shown. Figure 5 and Figure 6 It shows the case where the functional layer 13 is provided on the outermost surface of one side of the functional laminated board 1, Figure 7 The case where the functional layer 13 is provided on both outermost surfaces of the functional laminated board 1 is shown. Additionally, it can be done as Figure 6 As shown, in addition to the functional layer 13 provided on the outermost surface, a functional layer 13 is also provided inside the laminate. in addition, Figure 5 ~ Figure 7 Represents a laminate composed of two plastic films 11, which may also be as shown in the first embodiment image 3 , Figure 4 In that way, the laminate is composed of three or more plastic films. Furthermore, the functional layer can also be bonded to the uppermost plastic film by means ...

no. 3 approach

[0117] A third embodiment is a transparent conductive laminate for a touch panel, in which a transparent conductive layer is provided on at least one surface of the transparent laminate. its specific example Figure 8 ~ Figure 10 shown.

[0118] Figure 8 It is a transparent conductive laminate 6 for a touch panel having a transparent conductive layer 2 on one surface of the transparent laminate 10, and can be used as an upper electrode or a lower electrode of a resistive film touch panel, or as a member of a surface-type capacitive touch panel. Figure 9 It is a transparent conductive laminate 6 for a touch panel having a transparent conductive layer 2 on both sides of a transparent laminate 10, which can be used as a projection-type capacitive touch panel or a surface-type capacitive touch panel with an electromagnetic wave shielding function. Figure 10 It is a transparent conductive laminate 6 for a touch panel having two transparent conductive layers 2 interposed betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com