Welding structure for LED (light-emitting diode) array and circuit board thereof

A technology of LED array and welding structure, which is applied in the direction of printed circuit connected with non-printed electrical components, printed circuit components, electrical connection printed components, etc. Unable to power on and other problems, to achieve the effect of improving reliability, stable and reliable electrical connection, and reducing the probability of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical content disclosed in this application more detailed and complete, reference may be made to the accompanying drawings and the following various specific embodiments of the present invention. The same signs in the accompanying drawings represent the same or similar components. However, those of ordinary skill in the art should understand that the embodiments provided below are not intended to limit the scope of the present invention. In addition, the drawings are only for illustrative purposes, and are not drawn according to their original dimensions.

[0021] The specific implementation manners of each aspect of the present invention will be further described in detail below with reference to the accompanying drawings.

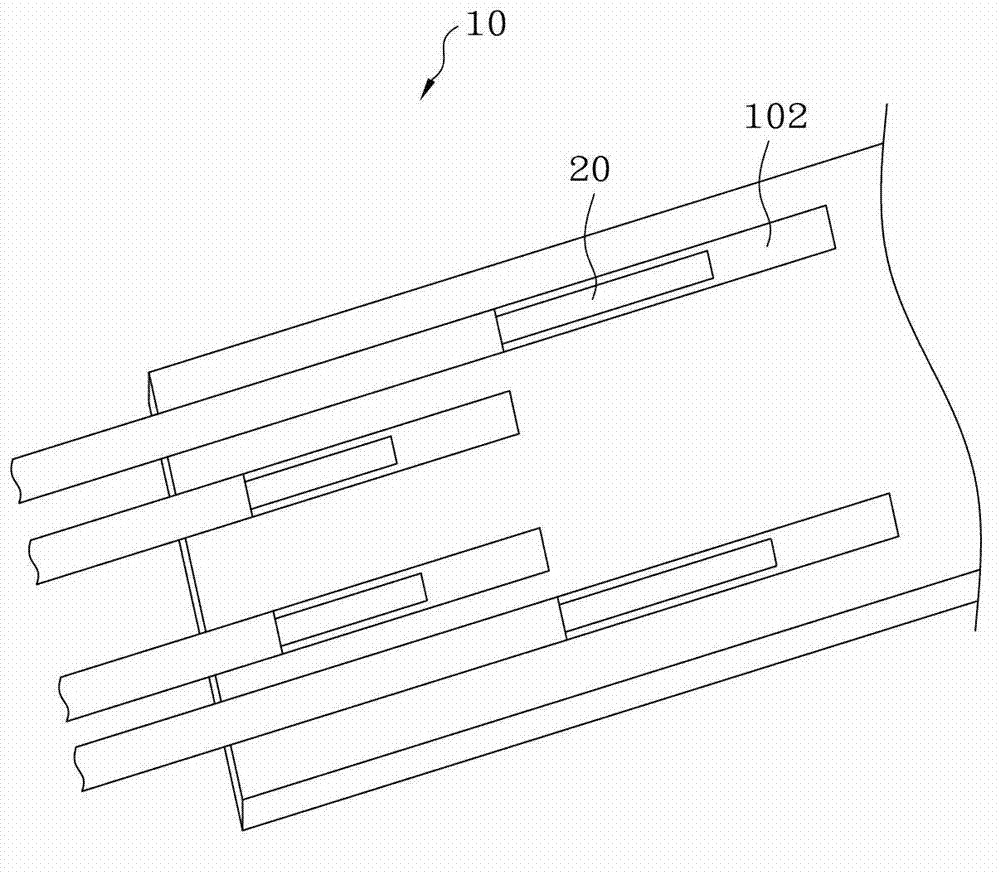

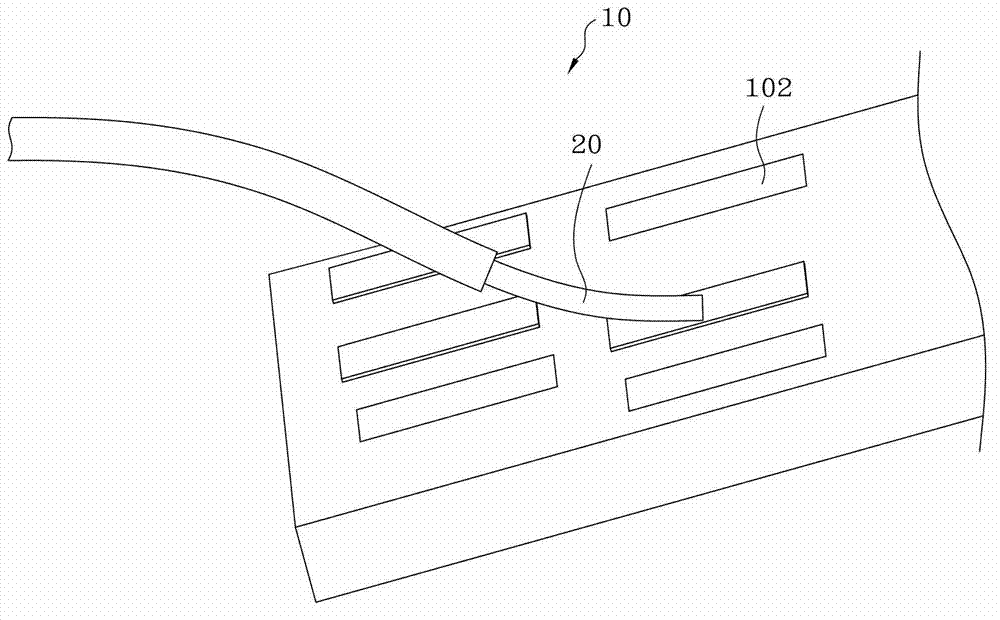

[0022] Figure 1A It shows a schematic diagram of a soldering structure in the prior art that uses a surface mount method to electrically connect an external power cord to a circuit board. Figure 1B show Figure 1A A schematic di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com