Multi-phase permanent magnet brushless direct current square wave motor capable of replacing Z4 series motors

A permanent magnet brushless DC and DC motor technology, which is applied in the direction of single motor speed/torque control and control of multiple DC motors, and can solve problems such as poor adaptability to the environment, corrosion, large volume, and heavy weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with embodiments.

[0017] The motor is mainly composed of the motor body, position and speed sensors and electronic switch control circuit.

[0018] figure 1 It is a structural diagram of the motor of the present invention.

[0019] In the figure: 1. Motor body; 2. Motor stator; 3. Motor rotor; 4. Rotor magnet; 5. Combined sensor stator; 6. Combined sensor rotor; 7. Fan.

[0020] The stator windings are generally made into three-phase, and can also be made into six-phase, nine-phase, and multi-phase. A tile-shaped magnet is attached to the axial surface of the rotor, and the permanent magnet is composed of a certain number of pole pairs (2p=2,4,6...). The three-phase stator windings are respectively connected with the corresponding power switch devices in the electronic switch circuit; the tracking rotor of the position and speed sensor is connected with the motor shaft.

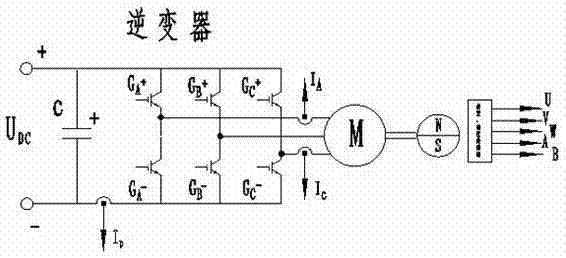

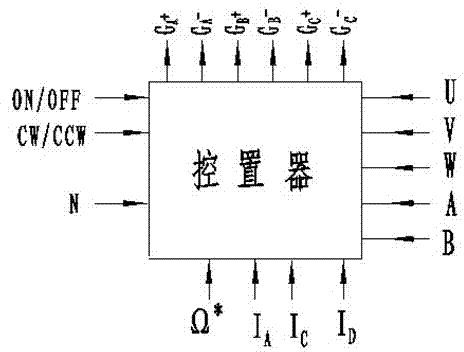

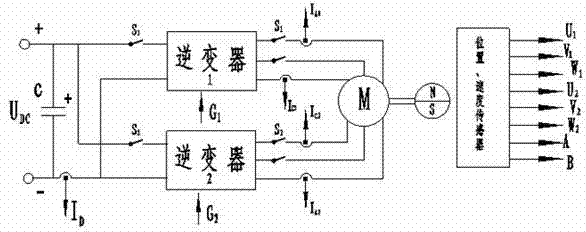

[0021] Figure 2-Figure 3 Shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com