Fabricating method of GaN-based light-emitting component with vertical structure

A gallium nitride-based, light-emitting element technology, applied to electrical components, semiconductor devices, circuits, etc., can solve problems such as low process yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention. It should be noted that, as long as there is no conflict, each embodiment and each feature in each embodiment of the present invention can be combined with each other, and the formed technical solutions are all within the protection scope of the present invention.

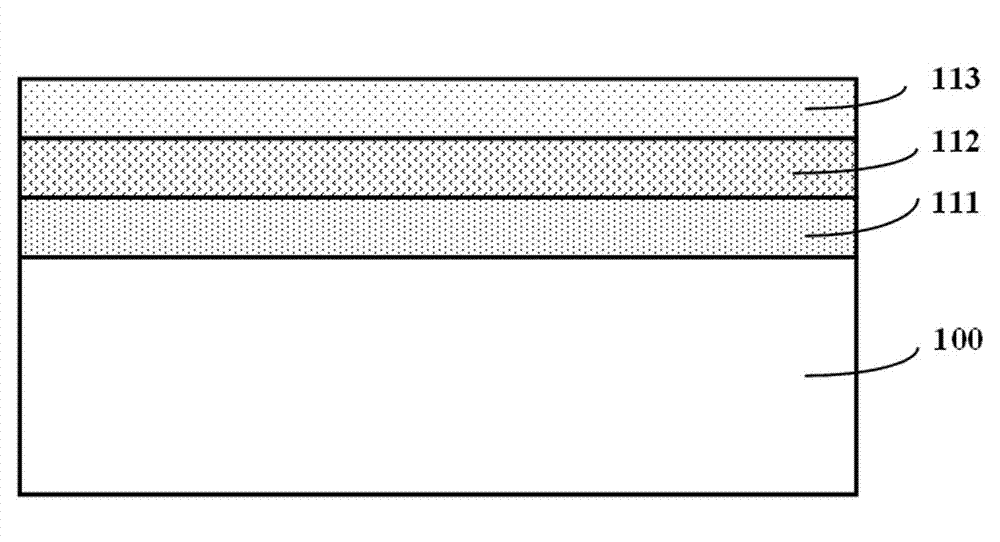

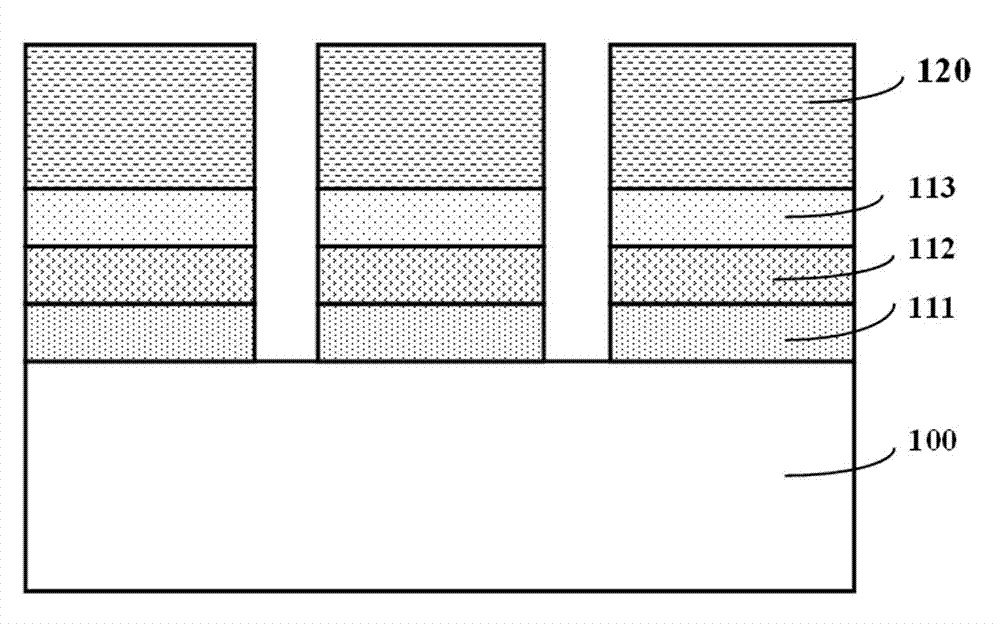

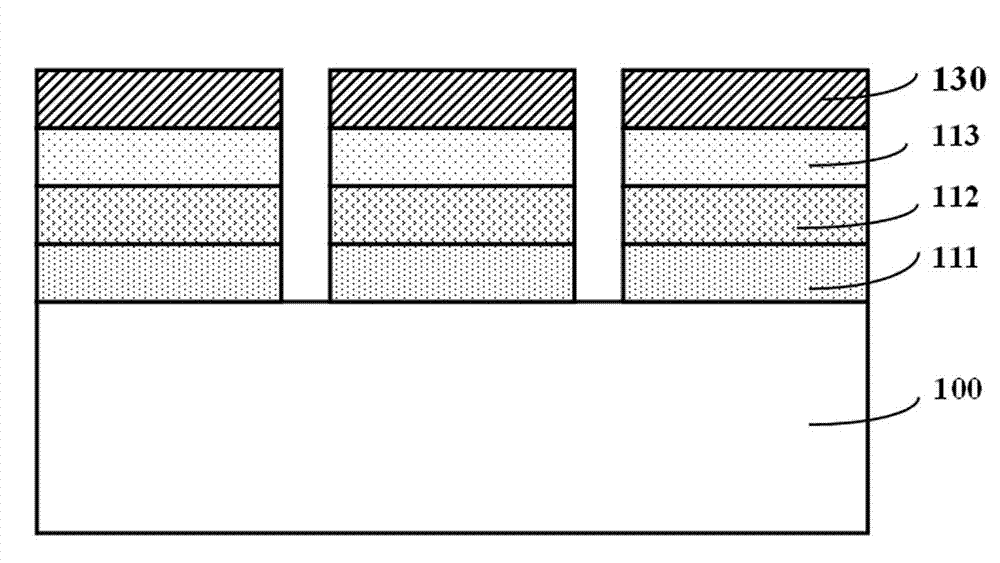

[0023] A method for manufacturing a gallium nitride-based light-emitting element with a vertical structure, the specific steps of which are as follows:

[0024] Such as Figure 7 As shown, a temporary substrate 200 is provided on which a GaN-based light-emitting epitaxial layer is epitaxially grown. It includes sequentially epitaxially growing an n-type layer 211 , a multi-quantum well (MQW) light-emitting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com