Monitoring apparatus of solar panel component laminating machines

A technology for solar panels and monitoring devices, applied in electrical program control, comprehensive factory control, etc., can solve problems such as difficulty in finding, affecting output and quality, and production confusion, and achieve easy management, high operational reliability, and reduced production stoppages. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

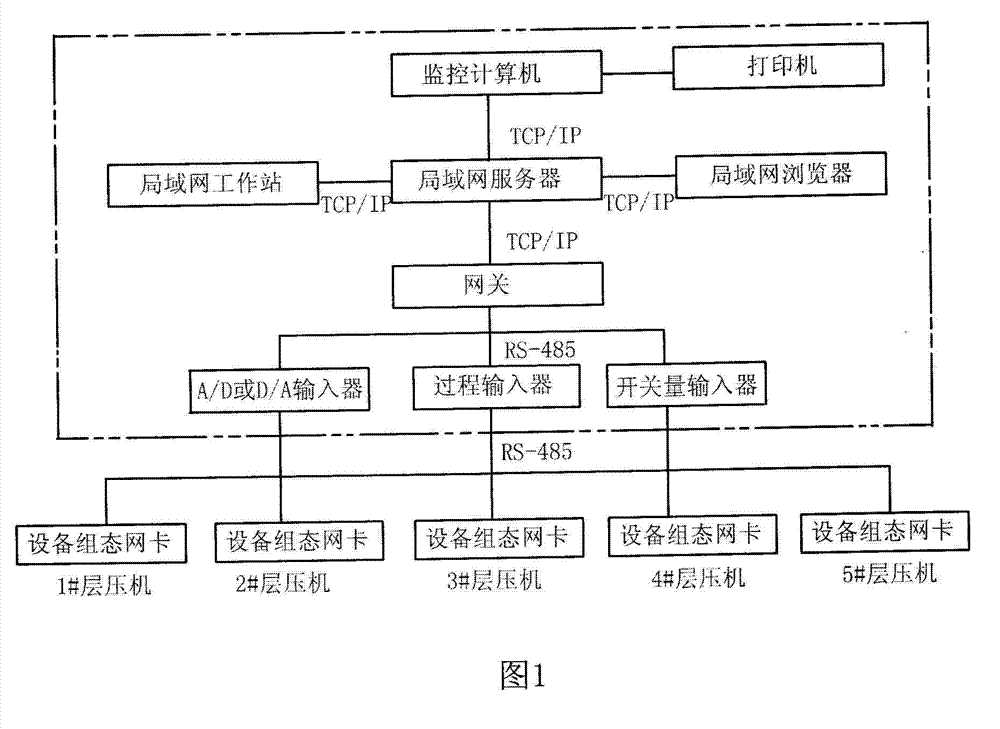

[0008] figure 1 Shown is the connection diagram of monitoring components of 5 laminators.

[0009] Take the monitoring of 5 lamination machines as an example:

[0010] Equipment configuration network cards are respectively installed on the 1st to 5th floor presses, and the connections between the network cards are respectively connected through the A / D or D / A input device, the process input device and the switch value input device, and then connected to the gateway and the local area network. The server and the monitoring computer are connected with circuits, the local area network server is connected with a local area network workstation and a local area network browser, and the monitoring computer is connected with a printer.

[0011] Working process of the present invention:

[0012] The device configuration network card sets the running state of the laminator, and the device configuration network card inputs the running state of the laminator to the gateway through the A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com