Cotton sample sampling manipulator used in cotton bale inspection

A manipulator, cotton bale technology, applied in the sampling device and other directions, can solve the problems of non-randomness and manual operation, and achieve the effects of good repeatability, convenient adjustment and fast sampling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention are described in detail below, and the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following embodiments.

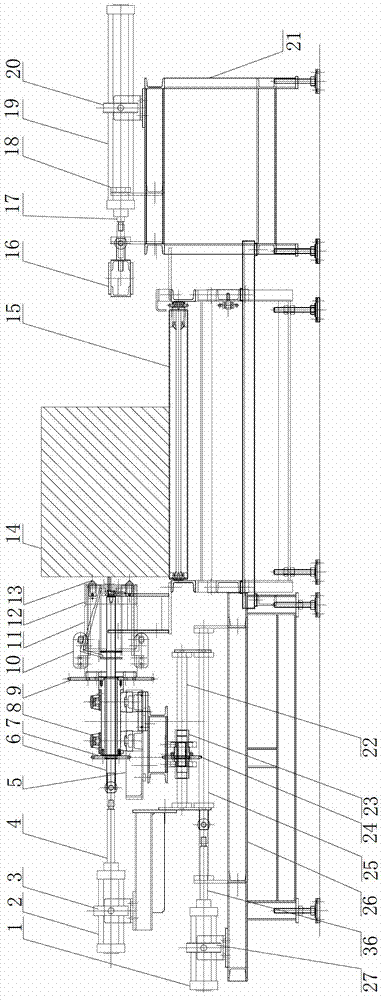

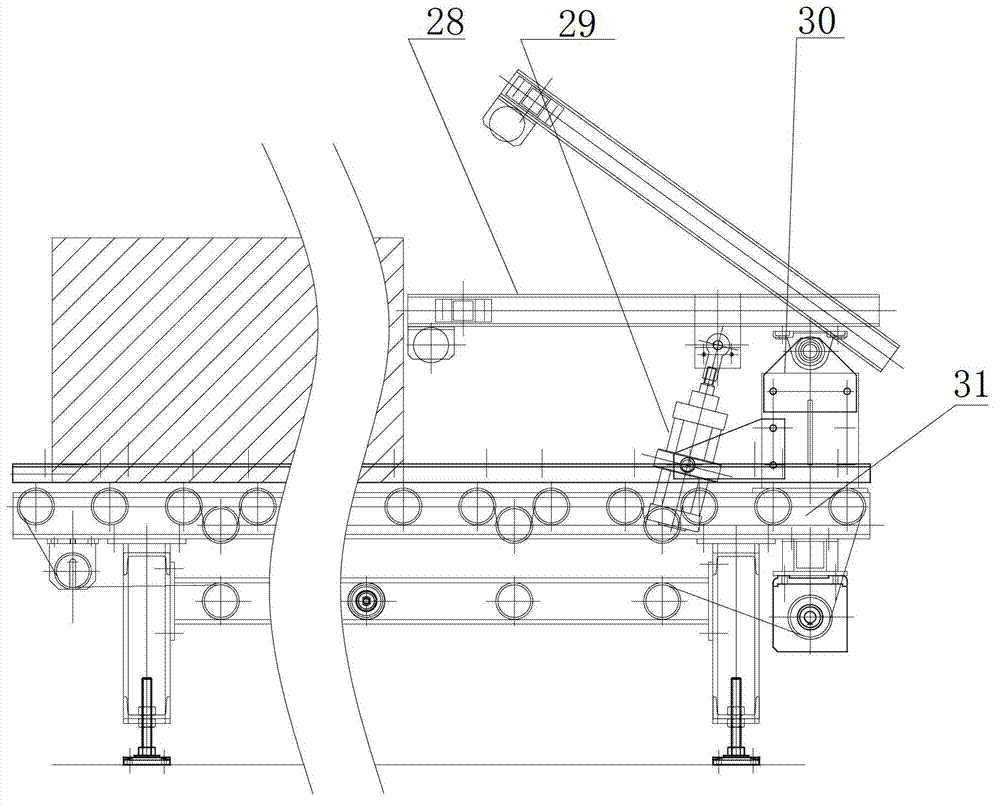

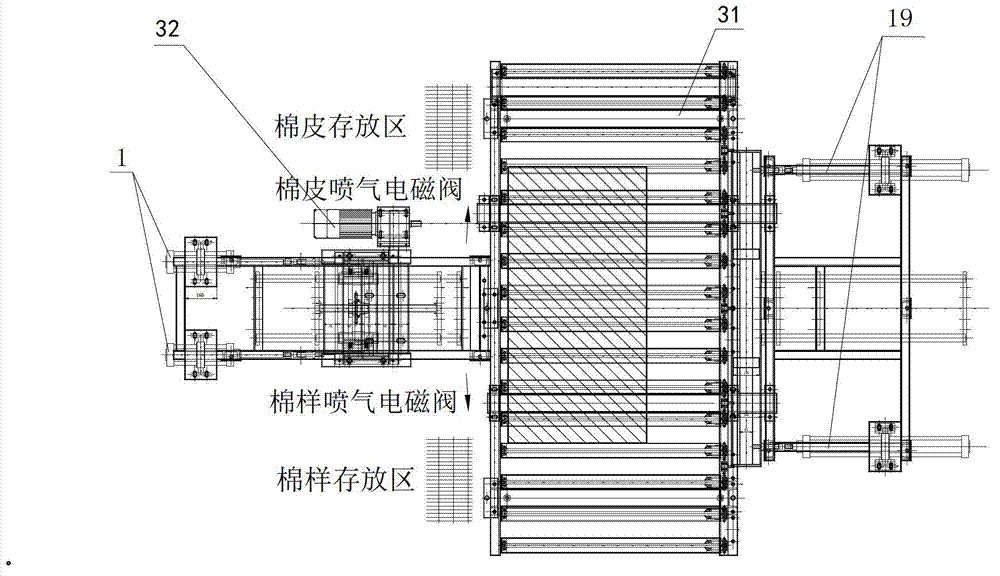

[0031] Such as figure 1 As shown, this embodiment includes: a cotton bale sampling manipulator, a cotton bale conveying raceway, and a cotton bale clamping device. The cotton bale sampling manipulator mainly includes a cotton sampling head, a sampling driving part, and a manipulator base driving part. The cotton sample sampling head completes the cutting and grabbing action of the cotton bale skin and the cotton fiber in the cotton bale; the sampling drive part completes the rotary feeding of the cotton sample sampling head, the grabbing and placing of the cotton sample grabbing claws and pushing the cotton sample out of the samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com