Driving device for oil pump

A driving device and oil pump technology, applied in the direction of machines/engines, pumps, pump components, etc., can solve the problems of complex transmission system, low work efficiency, difficult assembly, etc., and achieve simplified transmission system, high work efficiency and simple installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

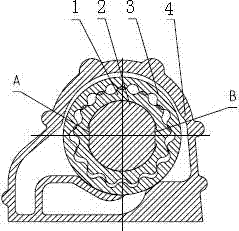

[0014] A driving device for an oil pump, including an inner rotor, a crankshaft, an outer rotor, and an oil pump volute. The inner rotor of the oil pump is set on the crankshaft through positioning surfaces A and B, the outer rotor is inlaid on the inner rotor, and the outermost is the machine The oil pump volute; the positioning surfaces A and B are used to prevent the relative rotation of the crankshaft and the inner rotor, and the crankshaft can directly drive the inner rotor of the oil pump to rotate to deliver high-pressure oil; the maximum fit clearance between the joint surfaces A and B of the crankshaft and the inner rotor 0.1mm, if possible, 0.03-0.1mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com