Method for preparing efficient far infrared nylon fibers

A nylon fiber and far-infrared technology is applied in the field of preparation of high-efficiency far-infrared nylon fibers, which can solve the problems of large particle size of far-infrared additives, cumbersome processing, rough fiber surface, etc., and achieves improved immunity, low cost, and preparation technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Weigh 51g MgCl at room temperature 2 ·6H 2 O and 45g AlCl 3 ·6H 2 O, add both to 265 ml H 2 O to make a mixed solution, add dropwise to NaOH / Na 2 CO 3 solution (pH=14), crystallized at 90°C for 4h, filtered, washed and dried to obtain Mg-Al-CO3 LDHs. The prepared Mg-Al-CO 3 LDHs were calcined at 500°C for 4h to obtain MMO, and 10kg polyamide 6 slices were weighed and dried in a vacuum oven at 120°C for 12h. Add MMO to the dried polyamide 6 chips according to 2wt% of the polymer chips and mix evenly, blend and granulate in a twin-screw extruder to obtain far-infrared functional masterbatches. The final chips were dried by vacuum blowing at 120°C, and melt-spun on a twin-screw composite spinning machine to obtain far-infrared nylon fibers at a spinning temperature of 275°C and a spinning speed of 3500m / min.

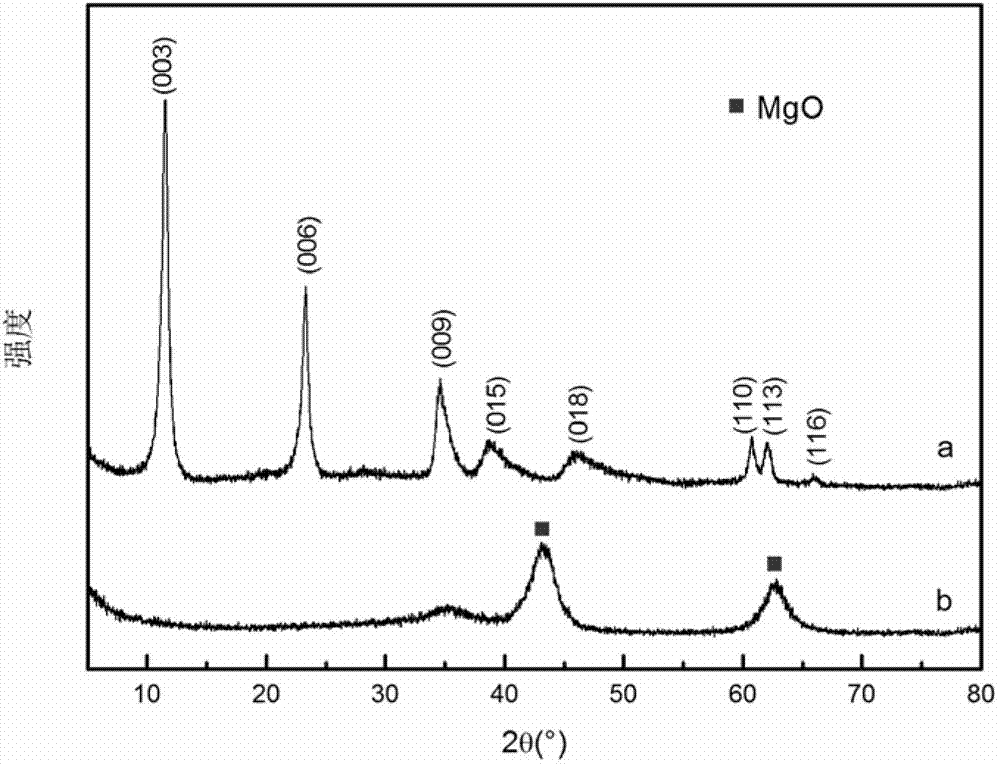

[0037] figure 1 Mg-Al-CO prepared for this example 3 X-ray diffraction patterns of LDHs and magnesium-aluminum composite oxide MMO. It can be seen from...

Embodiment 2

[0039] Weigh 51g MgCl at room temperature 2 ·6H 2 O and 45g AlCl 3 ·6H 2 O, add both to 265ml H 2 O to make a mixed solution, add dropwise to NaOH / Na 2 CO 3 The solution (pH=12) was crystallized at 80°C for 6h, filtered, washed and dried to obtain Mg-Al-CO 3 LDHs. Mg-Al-CO prepared by co-precipitation 3 LDHs were calcined at 500 °C for 4 h to obtain MMO, and 8 kg polyamide 6 slices were weighed and dried in a vacuum oven at 120 °C for 24 h. Add MMO to the dried polyamide 6 chips according to 3wt% of the polymer chips and mix evenly, and blend and granulate in a twin-screw extruder to obtain far-infrared functional masterbatches. The final chips were dried by vacuum blowing at 120°C, and melt-spun on a twin-screw composite spinning machine to obtain far-infrared nylon fibers. The spinning temperature was 265°C and the spinning speed was 4000m / min.

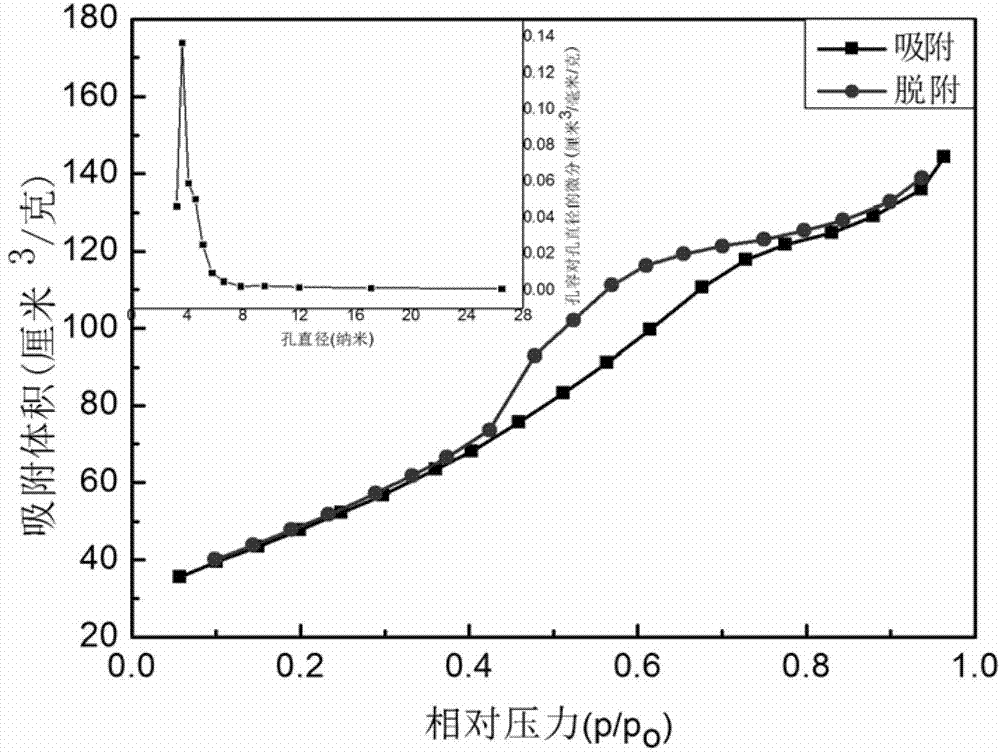

[0040] figure 2 Mg-Al-CO prepared for this example 3 N of MMO obtained by LDHs calcined at high temperature 2 Adso...

Embodiment 3

[0042] Weigh 51g MgCl at room temperature 2 ·6H 2 O and 45g AlCl 3 ·6H 2 O, add both to 265ml H 2 O to make a mixed solution, add dropwise to NaOH / Na 2 CO 3 solution (pH=14), crystallized at 80°C for 6h, filtered, washed and dried to obtain Mg-Al-CO 3 LDHs. The prepared Mg-Al-CO 3 LDHs were calcined at 400 °C for 5 h to obtain MMO, and 10 kg polyamide 6 slices were weighed and dried in a vacuum oven at 110 °C for 36 h. Add MMO to the dried polyamide 6 chips according to 3wt% of the polymer chips and mix evenly, and blend and granulate in a twin-screw extruder to obtain far-infrared functional masterbatches. The final slices were vacuum-dried at 120° C. and melt spun to obtain far-infrared nylon fibers. The spinning temperature was 280° C. and the spinning speed was 3500 m / min.

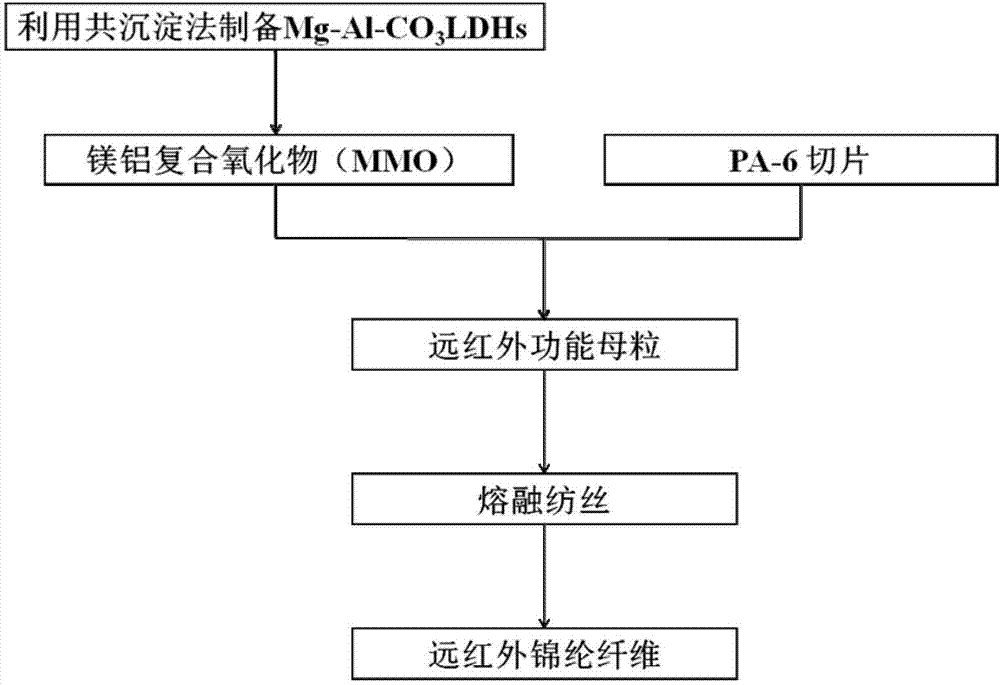

[0043] image 3 It is a flow chart of the preparation process of the new high-efficiency far-infrared nylon fiber in this example, and the far-infrared nylon fiber is prepared by the full g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com