LED (light-emitting diode) packaging adhesive and production method thereof

A technology of LED packaging and production methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve problems such as the refractive index cannot be raised, dead lights, and colloids turn yellow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] (1) Preparation method of component A base rubber

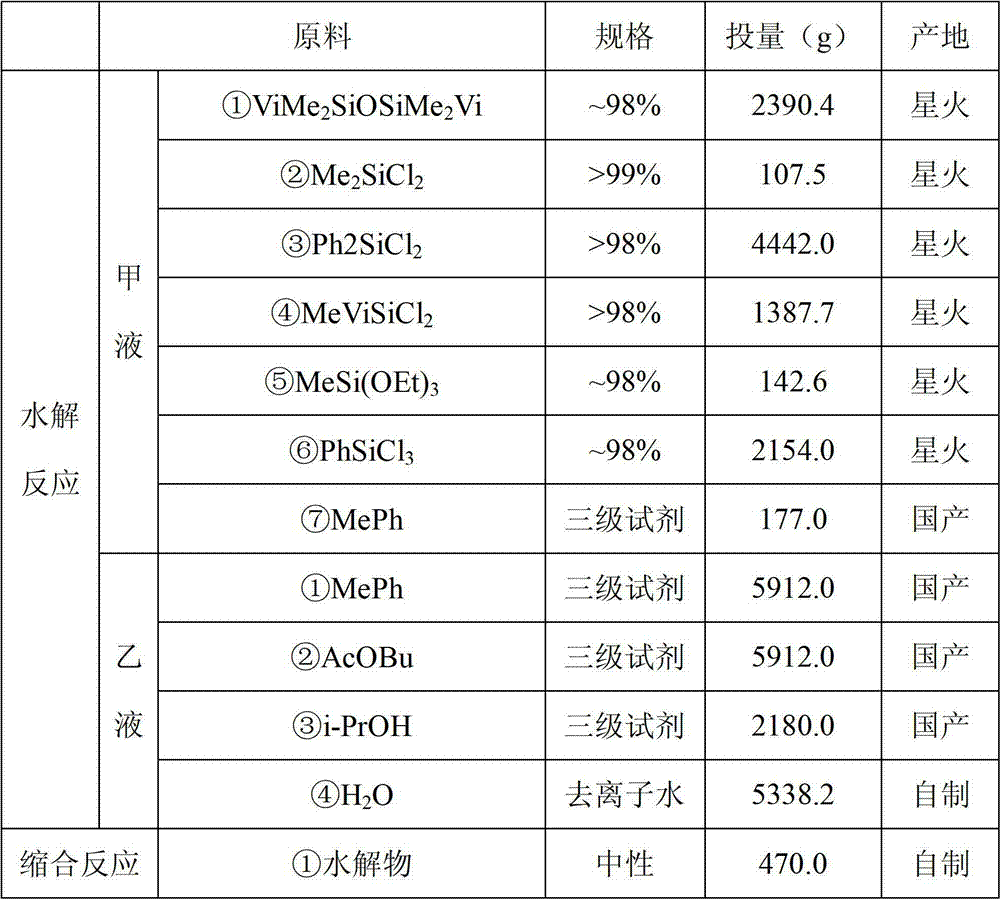

[0062] The raw materials and proportions are shown in Table 1.

[0063] Table 1

[0064]

[0065]

[0066] Steps

[0067] (i) Hydrolysis reaction: Add the specified amount of liquid A into the dropping bottle, add liquid B into the three-necked reaction bottle with a stirrer, thermometer, dropping bottle and reflux condenser, start stirring, and slowly dissolve the liquid A Drop into liquid B and carry out hydrolysis reaction at 25°C for 70 minutes. After the reaction is completed, transfer the reactant into a separatory funnel, separate the lower layer of acid water, and wash the hydrolyzate repeatedly with water until there is no Cl - (AgNO 3 inspection), filter, and reserve;

[0068] (ii) Condensation reaction: Add a specified amount of neutral hydrolyzate and NaOH catalyst into a three-necked reaction flask with a stirrer, thermometer, dropping funnel and reflux condenser, start stirring, and react at ref...

Embodiment 2

[0080] (1) Preparation method of component A base rubber

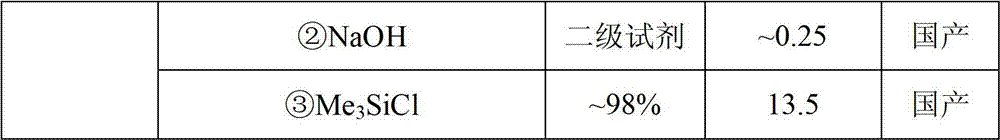

[0081] The raw materials and proportioning are shown in Table 3.

[0082] table 3

[0083]

[0084]

[0085] Steps

[0086] (i) Hydrolysis reaction: Add the specified amount of liquid A into the dropping bottle, add liquid B into the three-necked reaction bottle with a stirrer, thermometer, dropping bottle and reflux condenser, start stirring, and slowly dissolve the liquid A Drop into liquid B for 100 minutes at 10°C for hydrolysis reaction. After the reaction is over, transfer the reactant to a separatory funnel, remove the acidic water in the lower layer, and wash the hydrolyzate repeatedly with water until there is no Cl - (AgNO 3 inspection), filter, and reserve;

[0087](ii) Condensation reaction: Add a specified amount of neutral hydrolyzate and KOH catalyst into a three-necked reaction flask with a stirrer, thermometer, dropping funnel and reflux condenser, start stirring, and react at 115°C for 50 mi...

Embodiment 3

[0099] (1) Preparation method of component A base rubber

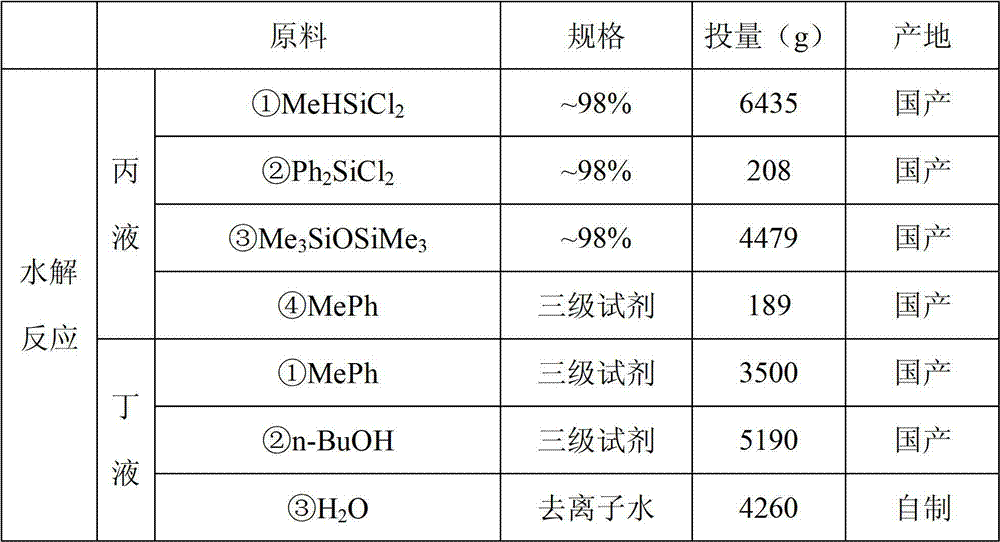

[0100] The raw materials and proportioning are shown in Table 5.

[0101] table 5

[0102]

[0103]

[0104] Steps

[0105] (i) Hydrolysis reaction: Add the specified amount of liquid A into the dropping bottle, add liquid B into the three-necked reaction bottle with a stirrer, thermometer, dropping bottle and reflux condenser, start stirring, and slowly dissolve the liquid A Drop into liquid B at 45°C for hydrolysis reaction for 50 minutes. After the reaction is over, transfer the reactant into a separatory funnel, separate the lower layer of acid water, and wash the hydrolyzate repeatedly with water until there is no Cl - (AgNO 3 inspection), filter, and reserve;

[0106] (ii) Condensation reaction: the specified amount of neutral hydrolyzate and KHCO 3 Add the catalyst into a three-necked reaction flask equipped with a stirrer, a thermometer, a dropping funnel and a reflux condenser, start stirring, and r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com