Preparation method of modified phenolic resin

A phenolic resin, modification technology, applied in the field of preparation of modified phenolic resin, can solve the problems of poor water solubility of modified phenolic resin, unfavorable on-site construction, complicated preparation process, etc., achieve high strength, improve brittleness, and good water solubility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

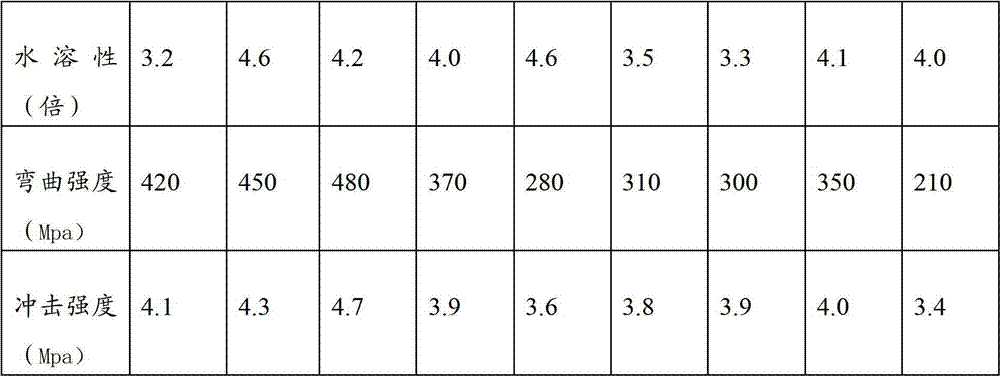

Embodiment 1

[0023] Take 100g of phenol, 5g of cardanol, 4g of 50% concentrated sulfuric acid and chlorosulfonic acid, put them in a reaction kettle, stir and mix, adjust the pH to 7.5 with sodium hydroxide, raise the temperature to 80°C, react for 3h, then cool down to 50°C ℃, add 38g formaldehyde, react for 1h, and obtain mixture A;

[0024] Take 100g of lignin and 150g of formaldehyde, put them in a reaction kettle, stir and mix them, adjust the pH to 7.5 with sodium hydroxide, raise the temperature to 50°C, and keep the temperature for 5 hours to obtain mixture B, which is hydroxymethylated lignin;

[0025] Mix mixture A and mixture B at a mass ratio of 1:7, raise the temperature to 70°C, and keep the temperature constant for 2 hours to obtain a modified phenolic resin.

Embodiment 2

[0027] Take 100g of phenol, 30g of cardanol, 20g of 50% concentrated sulfuric acid and sodium sulfite, put them in a reaction kettle, stir and mix, adjust the pH to 10 with sodium hydroxide, raise the temperature to 95°C, react for 1h, then cool down to 60°C, Add 137g formaldehyde, react for 3h, obtain mixture A;

[0028] Take 100g of lignin and 350g of formaldehyde, put them in a reaction kettle, stir and mix them, adjust the pH to 10 with sodium hydroxide, raise the temperature to 100°C, and keep the temperature for 3 hours to obtain mixture B, which is hydroxymethylated lignin;

[0029] Mix mixture A and mixture B at a mass ratio of 1:9, raise the temperature to 90°C, and keep the temperature constant for 1 hour to obtain a modified phenolic resin.

Embodiment 3

[0031] Take 100g of phenol, 17.5g of cardanol, and 12g of sodium sulfite, put them in a reaction kettle, stir and mix, adjust the pH to 8 with sodium hydroxide, raise the temperature to 90°C, react for 2h, then cool down to 55°C, add 87.5g of formaldehyde, and react 2h, obtain mixture A;

[0032] Take 100g of lignin and 250g of formaldehyde, put them in a reaction kettle, stir and mix them, adjust the pH to 8.5 with sodium hydroxide, raise the temperature to 75°C, and keep the temperature for 2 hours to obtain mixture B, which is hydroxymethylated lignin;

[0033] Mix mixture A and mixture B at a mass ratio of 1:8, raise the temperature to 80°C, and keep the temperature constant for 2 hours to obtain a modified phenolic resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com