Three-step two-stage method for producing marsh gas from municipal sludge by anaerobic fermentation

A technology of municipal sludge and anaerobic fermentation, which is applied in the field of solid waste recycling, can solve the problems of difficult biodegradation, removal, and inability to pass biochemical methods, and achieve the goals of increasing degradation rate, reducing sludge volume, and improving biodegradability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

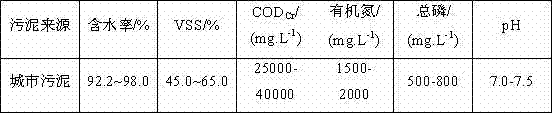

[0014] The properties of municipal sludge in a sewage treatment plant are shown in the table below.

[0015]

[0016] First put the sludge in an anaerobic digestion tank for mesophilic anaerobic digestion under the condition of 35±2°C, and the residence time is 30 days. After that, take the biogas residue from the anaerobic digestion tank and send it to a high-temperature and high-pressure reactor for wet oxidation. Cool to room temperature and send it to an anaerobic digestion tank for mesophilic anaerobic digestion at 35±2°C, with a residence time of 15 days. After three-step two-stage anaerobic fermentation, the sludge VSS removal rate (sludge digestibility) reaches 72.9%-81.3%, which is about 60%-110% higher than the traditional single-step mesophilic anaerobic digestion process, and the sludge volume Reduced by more than 85%, the formed filter cake can be directly landfilled. Example 2:

Embodiment 2

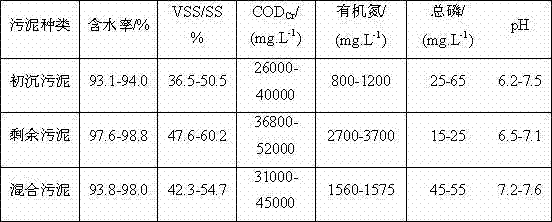

[0017] The properties of municipal sludge in a sewage treatment plant are shown in the table below.

[0018]

[0019] First put the sludge in an anaerobic digestion tank for mesophilic anaerobic digestion at 35±2°C, with a residence time of 20 days. Afterwards, take the biogas residue from the anaerobic digestion tank and send it to a high-temperature and high-pressure reactor for wet oxidation. The biogas residue is cooled to room temperature and sent to an anaerobic digestion tank for mesophilic anaerobic digestion at 35±2°C, with a residence time of 10 days. After three-step and two-stage anaerobic fermentation, the sludge COD removal rate reaches 87.6%-92.3%, and the VSS removal rate (sludge digestibility) reaches 67.4-71.5%. Afterwards, after centrifugal dehydration, the sludge volume is reduced by 95%. The formed filter cake can be directly landfilled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com