Slow agitating magnetic suspension liquid storage box

A technology of magnetic suspension and slow stirring, which is applied to mixer accessories, mixers with rotating stirring devices, dissolution, etc. It can solve problems such as insufficient concentration, failure to reach, troublesome replacement of expired magnetic suspension, etc., and achieve uniform concentration Consistent, easy fluid change results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

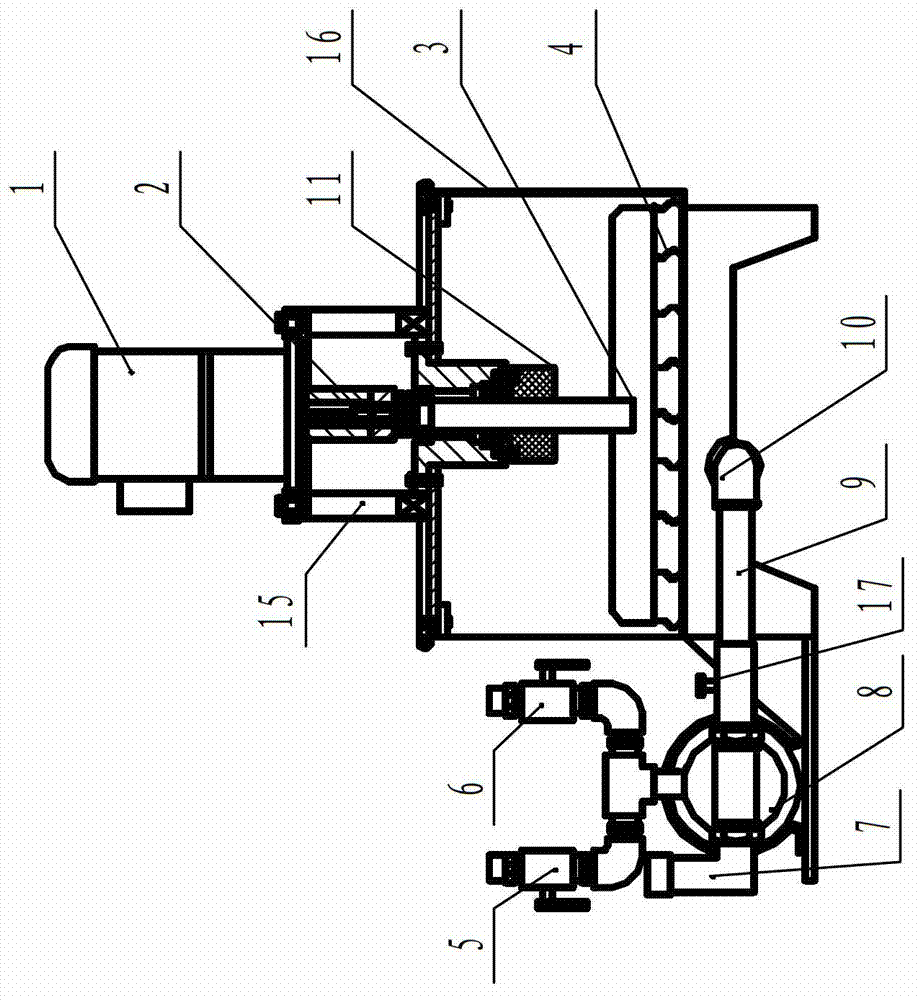

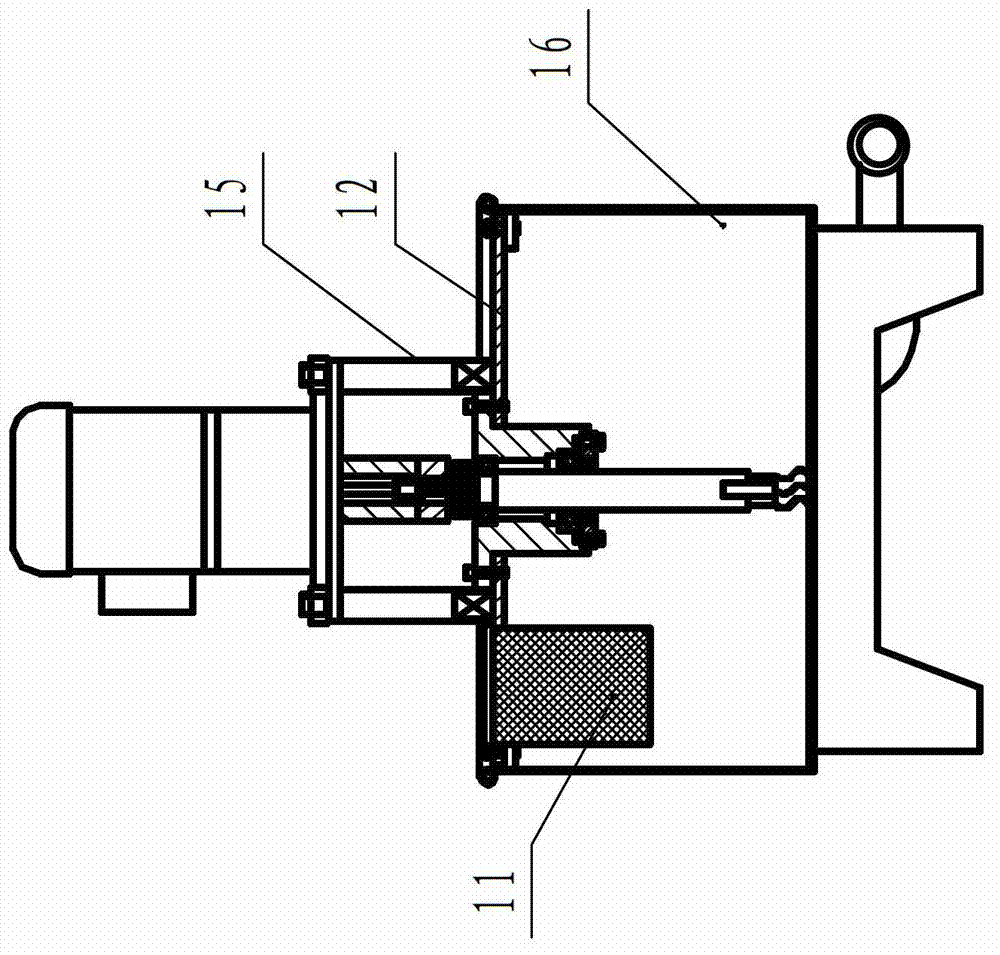

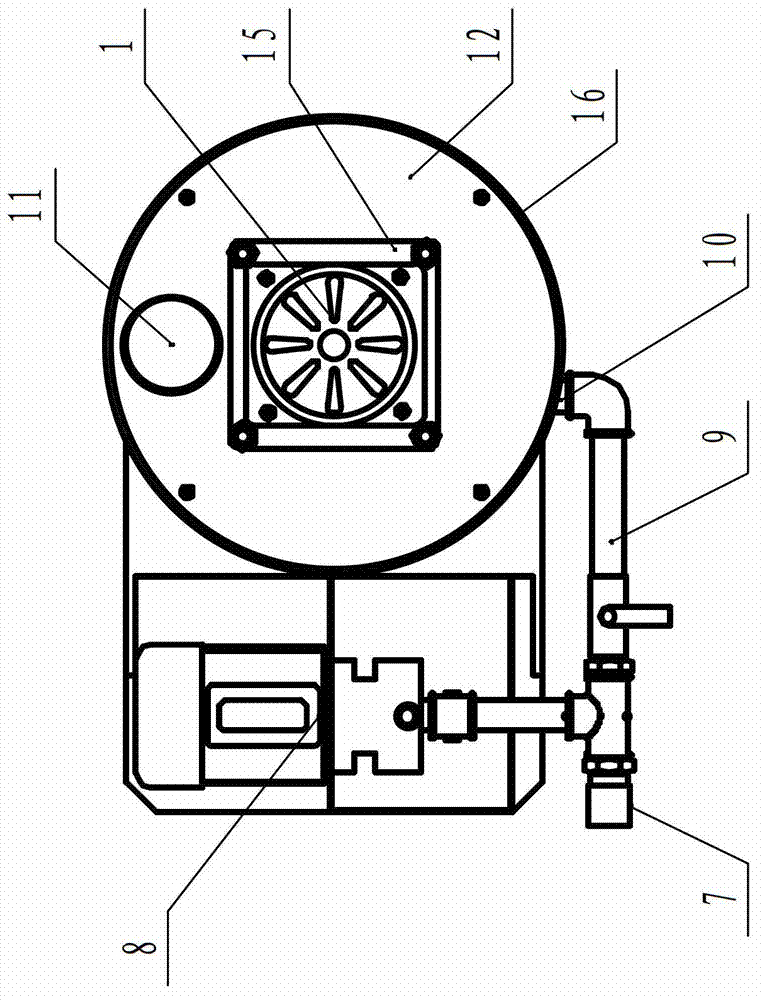

[0024] Describe the present invention in detail below in conjunction with accompanying drawing:

[0025] Such as Figure 1-3 As shown, the slow stirring magnetic suspension liquid storage tank includes a liquid storage tank 16 and a cover plate 12 on it, and the liquid storage tank 16 and the cover plate 12 on it are all circular; The mouth flange is arranged on the cover plate 12, and the stirring device is equipped on the liquid storage tank 16; the stirring device is powered by a reduction motor 1, and the speed of the reduction motor 1 is 20 rpm, and the reduction motor 1 uses four pillars 15 is supported on the cover plate 12; the agitator 3 is in the shape of an inverted "T", and the vertical shaft of the agitator 3 is connected with the power output shaft of the reduction motor 1 through the coupling 2; the lower part of the agitator 3 is equipped with a soft material Long brush 4, the bristles at the lower end of the long brush 4 are attached to the bottom of the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com