Moveable side striker plate for double-drum drier material pond

A material baffle and dryer technology, applied in evaporator accessories, chemical instruments and methods, evaporation, etc., can solve the problems of raw material liquid leakage, raw material liquid waste, poor production environment, etc., achieve dynamic sealing effect strengthening, prevent raw material Liquid leakage, easy inspection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

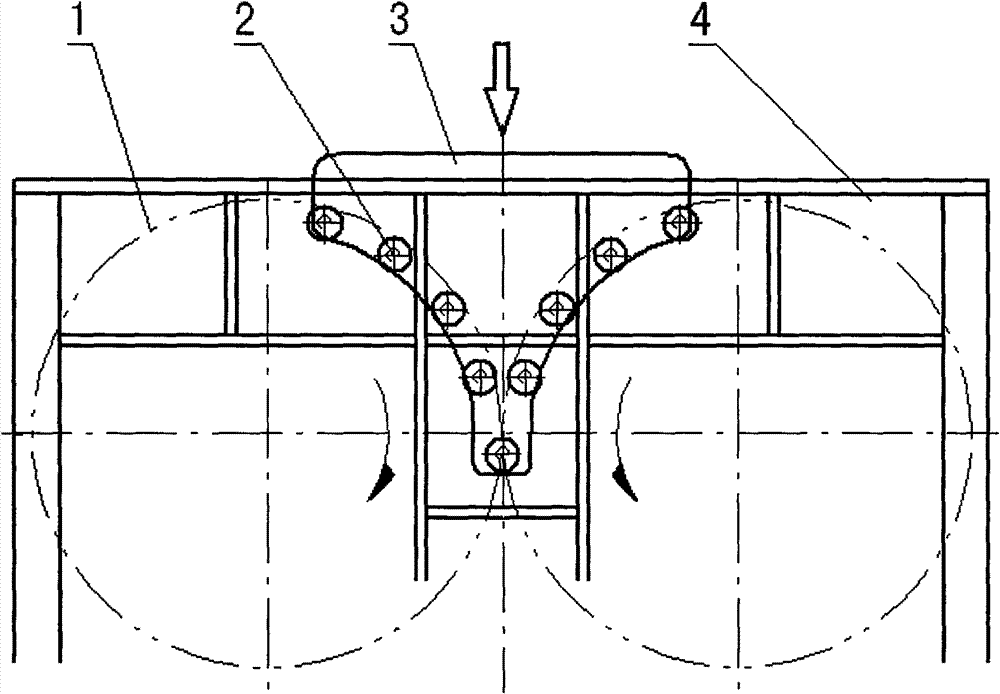

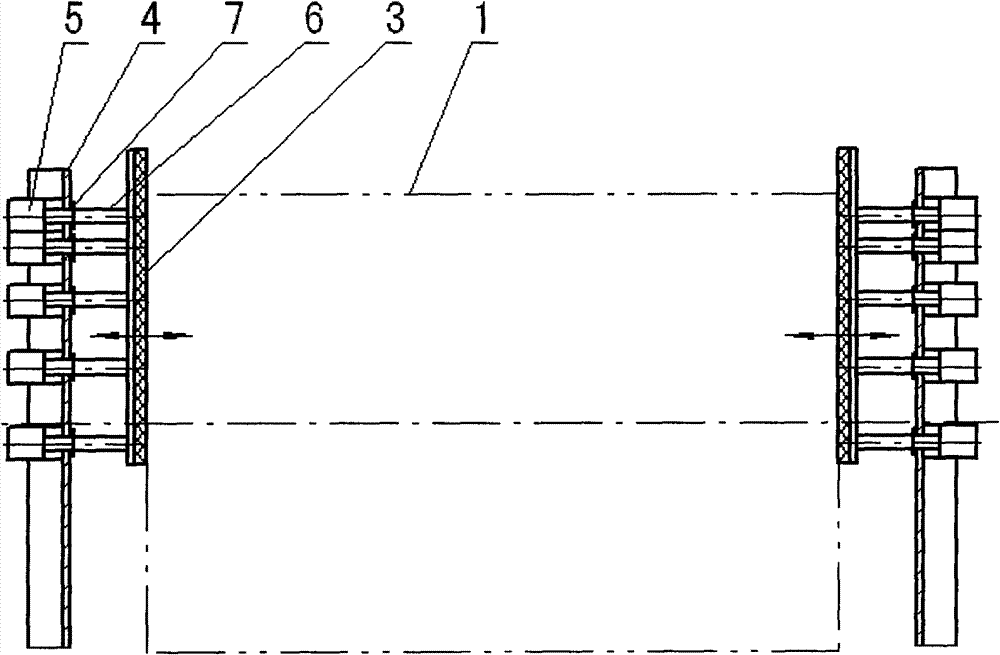

[0021] Example 1 is the use of the present invention on a double-drum dryer for processing modified starch. At the two adjacent parts of the two drums of the double-drum dryer, and at the two ends of the upper part, a complete set and a A movable side baffle plate for the feed pool of a double-drum dryer; the end wall plate (4) is fixedly arranged on the outside of the end faces of the two drums (1) of the double-drum dryer; 9 push rod assemblies (2) The push rod driving device (5) in the middle is fixedly arranged on the outer surface of the end wall board (4); one end of the nine push rods (6) is fixedly connected to the side baffle plate (3), and its The distribution of connection positions on the side baffle plate: the longitudinal centerline of the side baffle plate (3) is the symmetrical center, and the center line of the push rod (6) is arc-shaped and linearly arranged; the push rod After the other end of (6) passes through the through hole on the sealing device (7) and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com