Orally-dispersible multilayer tablet

A tablet and mouth-melting technology, which is applied in the field of multi-layer mouth-melting tablets and its preparation, can solve the problems of unusable and unusable mouth-melting tablets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

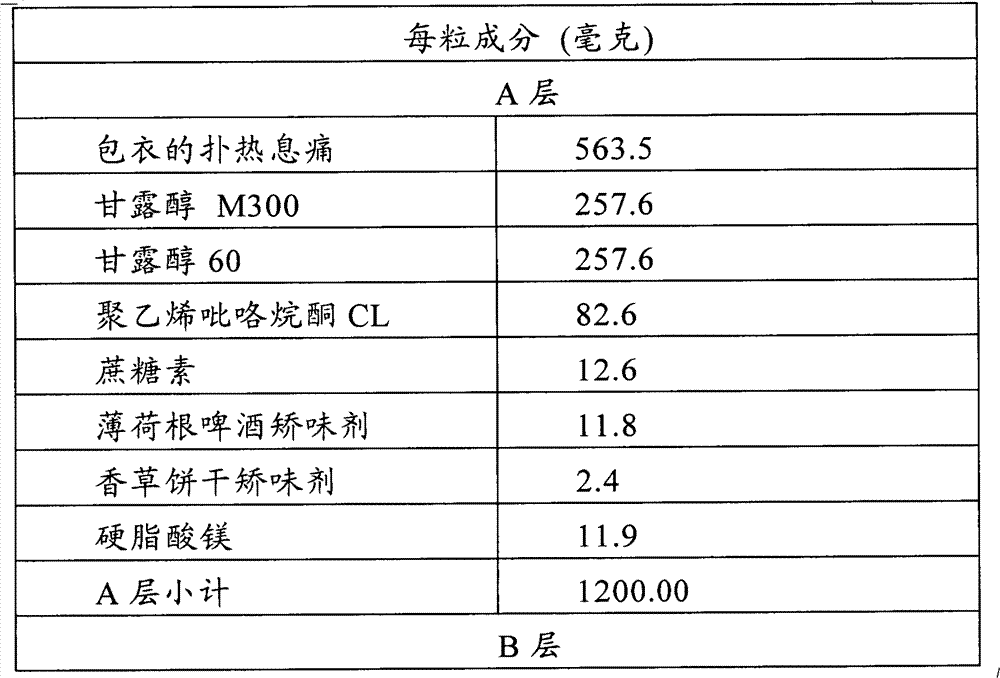

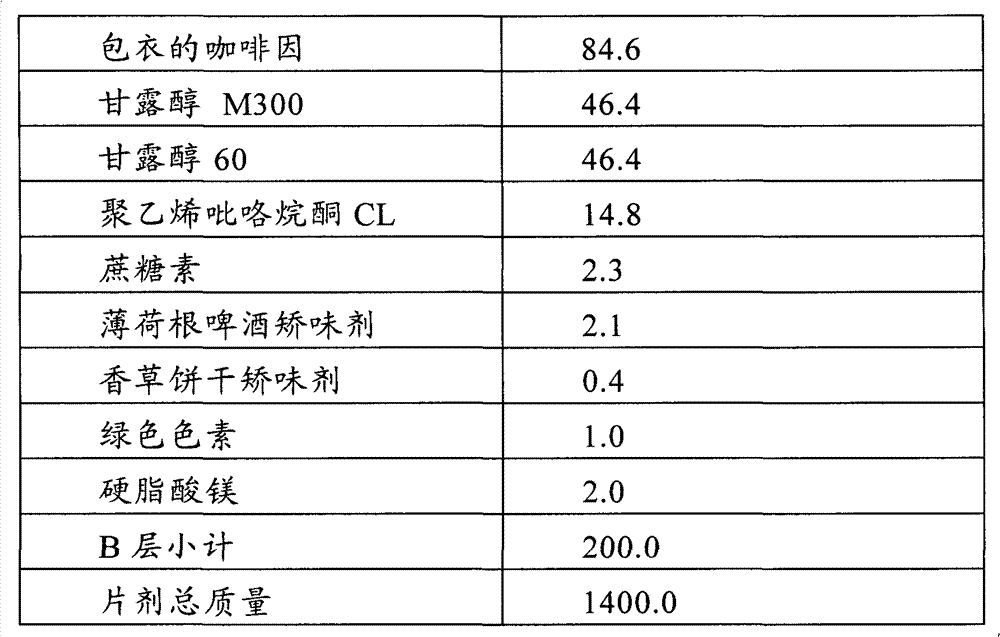

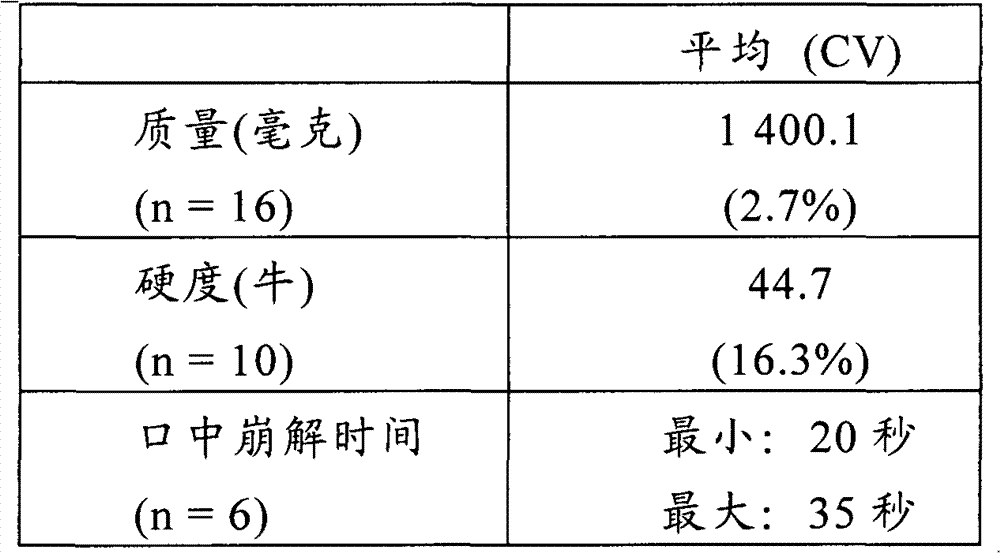

[0176] A bilayer, melt-in-the-mouth tablet containing 500 mg of paracetamol (acetaminophen) and 65 mg of caffeine was prepared.

[0177] 1 / mixture

[0178] The first layer of powder mix (Layer A) was prepared according to the recipe in Table 1.

[0179] Table 1

[0180]

Coated paracetamol

46.9%

Mannitol M300

21.5%

Mannitol 60

21.5%

6.9%

1.0%

Mint Root Beer Flavoring

1.0%

Vanilla Cookie Flavor

0.2%

1.0%

total

100%

[0181] Coated paracetamol granules are prepared by granulation and coating in a fluidized bed.

[0182] The particle size distribution of the particles is measured by laser diffraction: the size of the coated particles accounting for 98% of the total mass is between 150 microns and 500 microns.

[0183] The various components were stirred at a speed ...

Embodiment 2

[0207] A bilayer melt-in-mouth tablet containing 325 mg of paracetamol and 37.5 mg of tramadol hydrochloride (tramadol HCL) was prepared.

[0208] A batch of 14,000 bilayer tablets was prepared in the following manner.

[0209] 1 / mixture

[0210] All mixtures were prepared as in Example 1.

[0211] The first layer of mixture (A layer, quality 800 mg) at first includes the polymer mixture coated with 20% (coating polymer dry weight ratio coating particle weight) ( E100 / The ratio of NE30D is 67 / 33) paracetamol in the coating layer, and also includes tablet excipients, and the ratio is shown in Table 5.

[0212] table 5

[0213]

Composition (% mass / mass)

Coated paracetamol

46.0%

Mannitol M300

20.6%

Mannitol 60

20.6%

9.4%

1.9%

Mint Root Beer Flavoring

0.9%

0.6%

total

100%

[0214] The second layer ...

Embodiment 3

[0234] Two-layer, orally dissolving tablets containing 200 mg of ibuprofen and 37.5 mg of tramadol hydrochloride (tramadol HCL) were prepared.

[0235] A batch of 14,000 bilayer tablets was prepared in the following manner.

[0236] 1 / mixture

[0237] All mixtures were prepared as in Example 1.

[0238] Coated ibuprofen granules are prepared in a fluidized bed by granulation and coating.

[0239] The particle size distribution is measured by laser diffraction: D 50% 258 microns, 2% of the total mass of coated particles is less than 90 microns, and 1% of the total mass of coated particles is greater than 500 microns.

[0240] The first layer mixture (layer A) at first includes the ibuprofen of the coating layer coated with 13.7% (dry weight of the coating polymer to the weight of the coating granules) ethylcellulose N7, and also includes tableting excipients, the ratio See Table 9.

[0241] Table 9

[0242]

[0243] The second layer of mixture (layer B) at first includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com