Cut steamed bun making machine

A steamed bun machine and steamed bun technology, which is applied in the directions of dough forming and cutting equipment, etc., can solve the problems of small production volume, difficulty in meeting demand for steamed buns, and large demand for steamed buns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

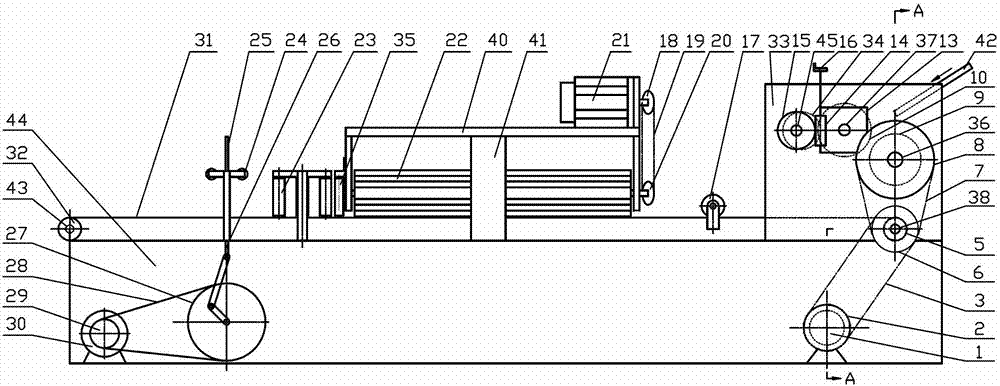

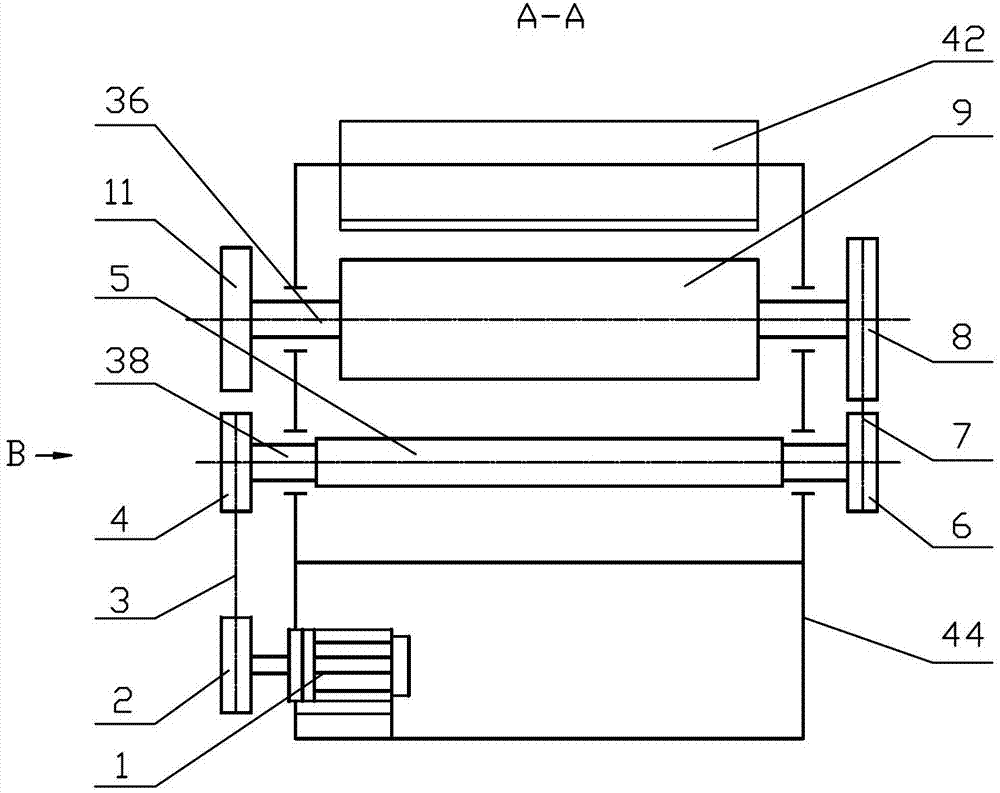

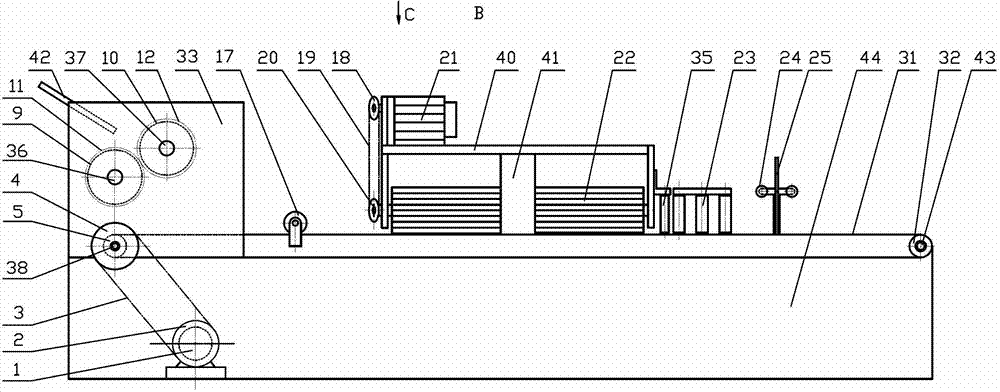

[0032] as attached figure 1 , 2 , Shown in 3 and 4, a kind of knife-cut steamed bun machine mainly comprises frame 44 and is arranged on frame 44 and enters the dough mechanism, pressing mechanism, conveying structure, rolling structure and steamed bread cutting mechanism.

[0033] Described face pressing mechanism comprises the first face pressing roller 9 and the second face pressing roller 10 that rotate around self axis respectively, and the rotation direction of first face pressing roller 9, the second face pressing roller 10 is opposite; Between the roller 9 and the second noodle-pressing roller 10 is a noodle-pressing work area; the upper end of the noodle-pressing work area is the noodle-in end, and the lower end is the noodle-out end.

[0034] The noodle feeding mechanism is located obliquely above the noodle feeding end of the noodle pressing working area. The dough feeding mechanism 42 is made up of a plurality of side by side feeding rollers. The conveying end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com