Detoxification with reducing agents

一种还原剂、预处理的技术,应用在用添加化合物以刺激生长、生物燃料、发酵等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

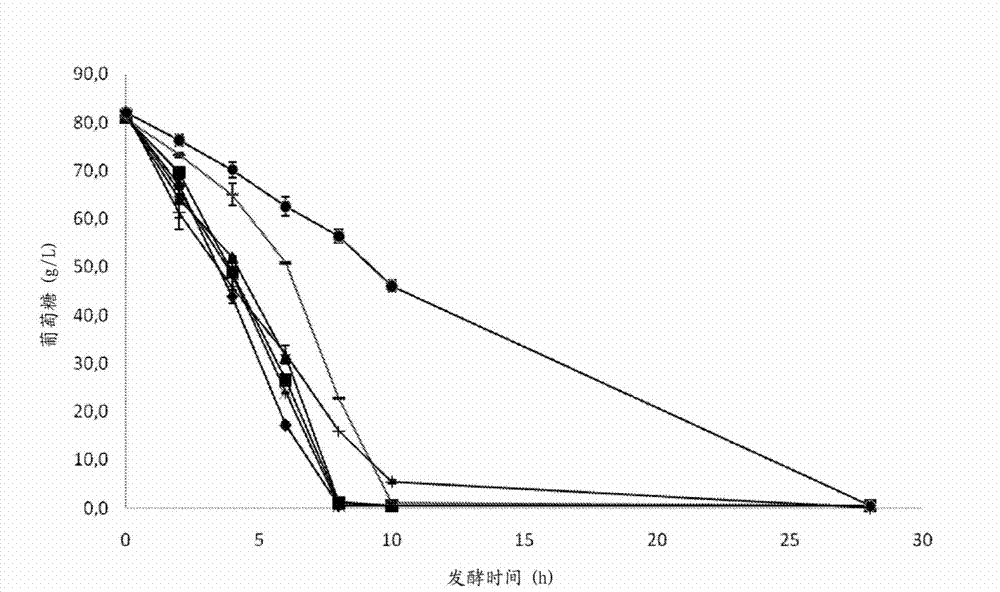

[0011] As a first aspect of the present invention there is provided a method for reducing fermentation inhibition in a process for the production of a chemical of interest from pretreated cellulosic material comprising enzymatic hydrolysis of the pretreated cellulosic material and fermentation of hydrolyzed material,

[0012] Therein, the fermentation inhibition of the material subjected to fermentation is reduced by adding at least one reducing agent to the pretreated material or the hydrolyzed material.

[0013] "Fermentation" is a process known to those skilled in the art, and is generally performed by microorganisms.

[0014] "Fermentation inhibition"refers to a negative effect on a fermentation reaction, for example, reducing the rate of a fermentation reaction or the total amount of target product produced in a fermentation reaction. Thus, "reducing fermentation inhibition" means reducing such negative effects. Thus, reducing fermentation inhibition may be detoxificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com