Cement admixture for repair, cement composition for repair using same, and cement mortar material for repair

A technology of cement composition and cement mortar, which is applied in the field of cement mortar materials for repair, can solve the problems of no display hardening delay, uneven processing surface, influence of resurfacing of paving materials, etc., and achieve the effect of excellent storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

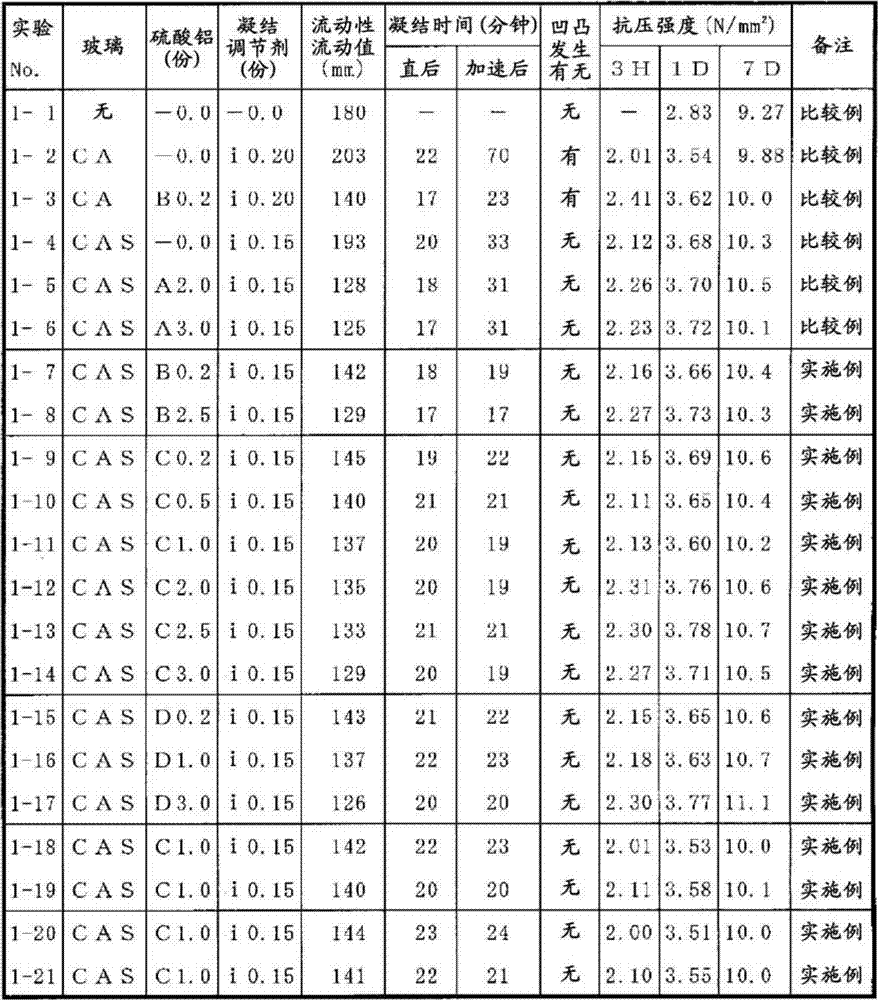

experiment example 1

[0074] Prepare 100 parts of gypsum with CAS glass and 100 parts of gypsum with respect to 100 parts of CAS glass. In 100 parts of cement and 100 parts of cement and gypsum, make 20 parts of gypsum. Mix table with 100 parts of binder The aluminum sulfate shown in 1, the coagulation regulator and 150 parts of fine aggregate are used to prepare the cement mortar material. Water was added to the prepared cement mortar material so that the water / binder ratio became 70%, and it was kneaded for 3 minutes using a mortar mixer to prepare cement mortar (hereinafter, simply referred to as mortar). Using the prepared mortar, measure its unevenness, setting time and compressive strength during hardening in a constant temperature and humidity chamber at 20°C and 80% RH.

[0075] In addition, 500 g of the prepared cement mortar material was weighed, sealed in a polyethylene bag, heat-sealed, and placed on the top plate of the sample stand. The sample stage consists of a top plate and legs m...

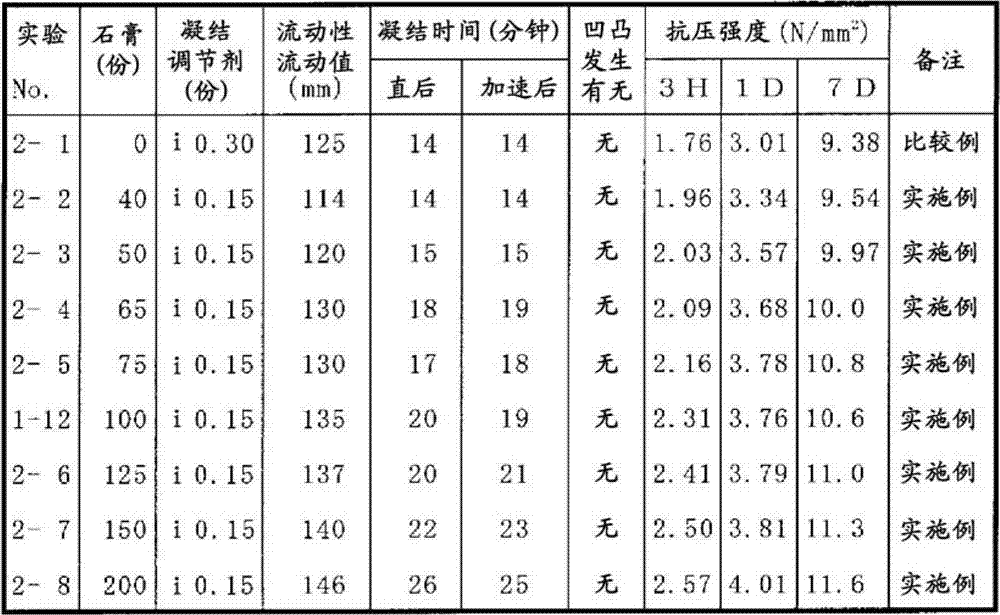

experiment example 2

[0107] Preparation contains CAS glass and 100 parts of CAS glass and gypsum as shown in Table 2. In 100 parts of the binder containing cement and the quick-hardening component, make the quick-hardening component 20 parts, relative to 100 parts of the binder. 2.0 parts of aluminum sulfate C, the coagulation regulator shown in Table 2, and 150 parts of fine aggregate were mixed one by one to prepare a cement mortar material, and it was carried out in the same manner as in Experimental Example 1. The results are also listed in Table 2.

[0108] [Table 2]

[0109]

[0110] Gypsum is 100 parts (parts) relative to CAS glass, aluminum sulfate and coagulation regulator are 100 parts (parts) relative to the binding material, the setting time is immediately after mixing, and after acceleration is 10 days after the accelerated test. 3H, 1D and 7D of strength are the compressive strength after 3 hours, 1 day and 7 days, respectively.

[0111] The following results can be seen from Ta...

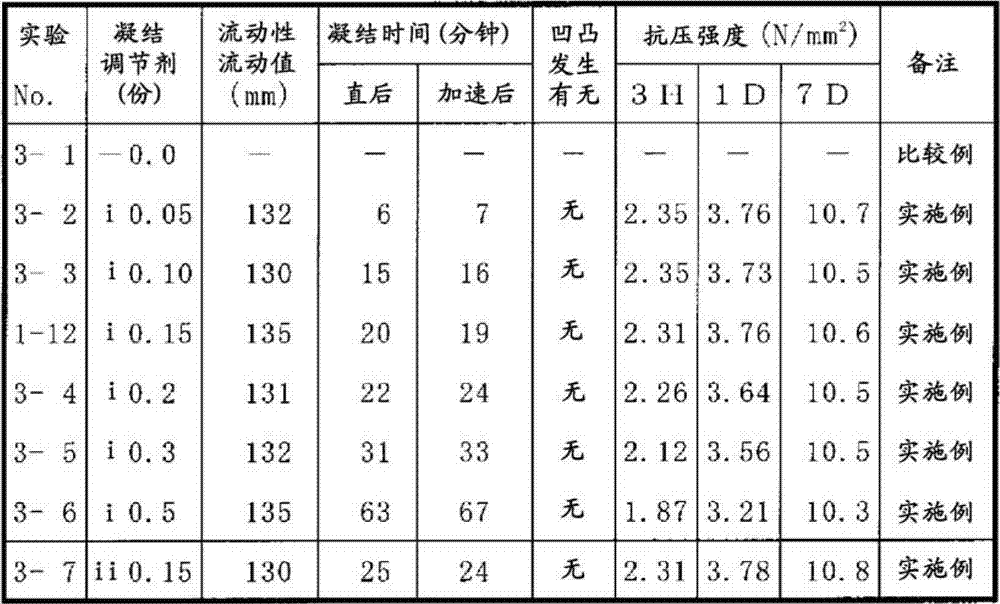

experiment example 3

[0115] Prepare a rapid-hardening component containing CAS glass and 100 parts of gypsum to 100 parts of CAS glass, and mix 20 parts of the rapid-setting component in 100 parts of the binder containing cement and the quick-hardening component to 100 parts of the binder 2.0 parts of aluminum sulfate C, the coagulation regulator shown in Table 3, and 150 parts of fine aggregate were used to prepare a cement mortar material, and it was carried out in the same manner as Experimental Example 1 except that. The results are also listed in Table 3.

[0116]

[0117] Coagulation regulator ii: citric acid, commercially available

[0118] [table 3]

[0119]

[0120] The coagulation regulator is 100 parts (parts) relative to the binding material. The straight time after the coagulation time is just after mixing, and the accelerated time is 10 days. After the accelerated test, the 3H, 1D and 7D of the compressive strength are respectively 3 hours, 1 day and The compressive strength a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com