Reflective solar concentrator without optical equalizing rod

A concentrator and concentrating light technology, which is applied in the field of solar concentrators, can solve the problems of increased current impedance, increased light consumption, and reduced power generation efficiency, and achieves the effects of uniform illumination, high power generation efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] specific implementation

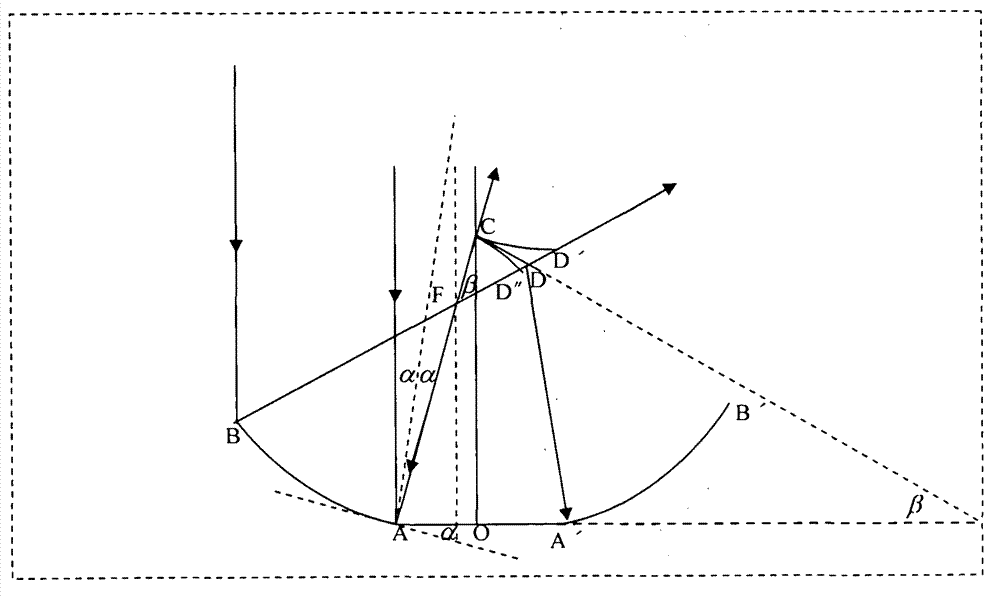

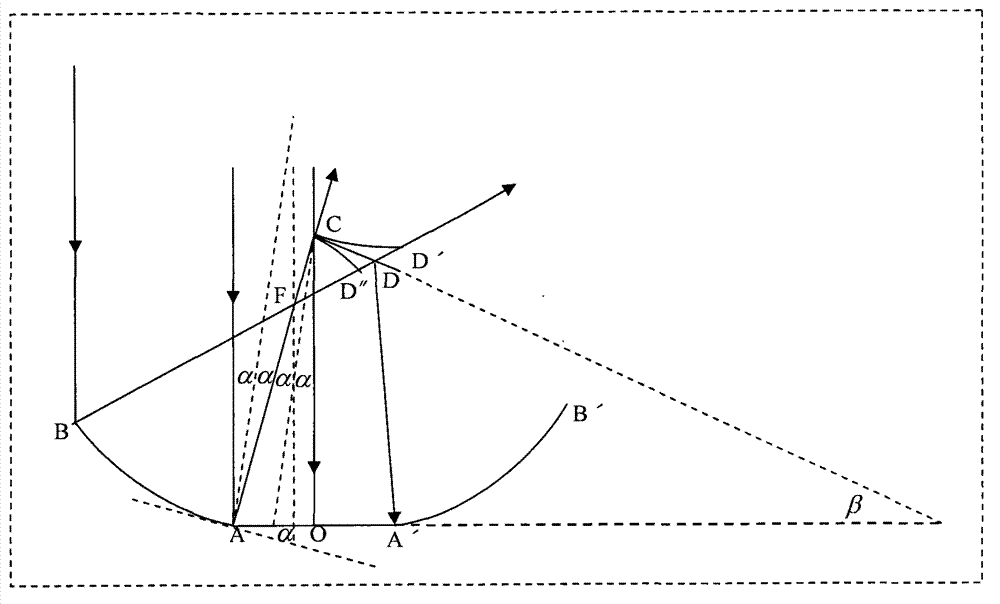

[0038] In the study of the reflective concentrator, since the reflective parabola can be a paraboloid of revolution formed by the parabola rotating around the central axis or a parabolic cylinder formed by the parabola extending along the axis perpendicular to the plane of the parabola, in order to simplify the problem, we can first In-dimensional research. like figure 1 In , both the primary reflector and the secondary reflector can be simplified as parabola segments. The primary reflector can be a paraboloid of revolution formed by rotating the parabola segment AB and its symmetric line segment relative to the central axis together around the central axis or a parabolic cylinder extending along an axis perpendicular to the plane. The secondary reflector can be formed by the parabola segment CD is a paraboloid of revolution formed by rotating around the central axis together with its symmetric line segment relative to the central axis, or a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com