Novel self-aligning roller bearing allowing wide-angle deflection

A self-aligning roller bearing, a large-angle technology, applied in the field of bearings, can solve the problems that the self-aligning roller bearing cannot meet the requirements, the deflection angle is small, and the main engine cannot be satisfied, so as to increase the mutual deflection angle and reduce the contact. angle, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

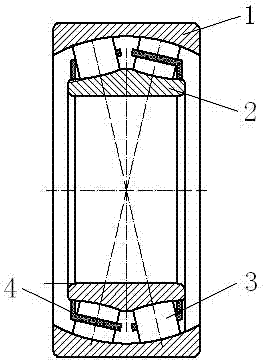

[0024] Take spherical roller bearing 23224CC as an example, such as figure 1 As shown, it includes: outer ring 1, inner ring 2, rolling elements 3 and cage 4, the width of the outer ring 1 is greater than the width of the inner ring 2, and the outer ring 1 is provided with a spherical raceway , the inner ring 2 is a double raceway inner ring with a first raceway and a second raceway, the cage 4 and rolling elements 3 have two sets, and one set is set on the spherical raceway of the outer ring 1 between the first raceway of the inner ring 2 and the other set between the spherical raceway of the outer ring 1 and the second raceway of the inner ring 2 .

[0025] Its external dimensions are: inner diameter 120mm×outer diameter 215mm×inner ring 2 width 76mm, outer ring 1 width 95mm, which is 125% of the inner ring 2 width; at the same time, the installation distance of the two sets of rolling elements 3 becomes smaller , so that the contact angle is reduced by 0.77°, from the orig...

Embodiment 2

[0027] Take spherical roller bearing 22322CC as an example, such as figure 1 As shown, it includes: outer ring 1, inner ring 2, rolling elements 3 and cage 4, the width of the outer ring 1 is greater than the width of the inner ring 2, and the outer ring 1 is provided with a spherical raceway , the inner ring 2 is a double raceway inner ring with a first raceway and a second raceway, the cage 4 and rolling elements 3 have two sets, and one set is set on the spherical raceway of the outer ring 1 between the first raceway of the inner ring 2 and the other set between the spherical raceway of the outer ring 1 and the second raceway of the inner ring 2 .

[0028] Its external dimensions are: inner diameter 110mm×outer diameter 240mm×inner ring 2 width 80mm, outer ring 1 width 105mm, which is 131.25% of the inner ring 2 width; at the same time, the installation distance of the two sets of rolling elements 3 becomes smaller , so that the contact angle is reduced by 0.6°, from the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com