Semi-prefabricating construction process for concrete thin-wall lower return eave

A kind of construction technology, semi-prefabrication technology, applied in the direction of construction, building structure, building material processing, etc., can solve the problems of high difficulty in gap treatment, affecting the appearance effect, cracking, etc., to save construction materials, save construction materials and labor The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

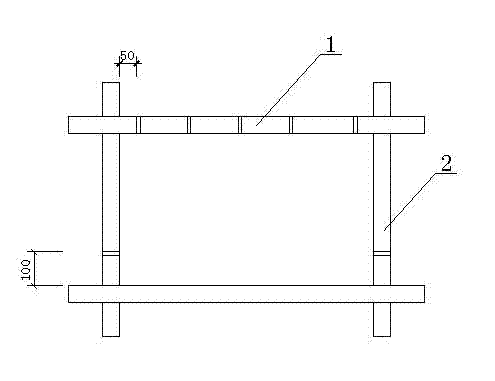

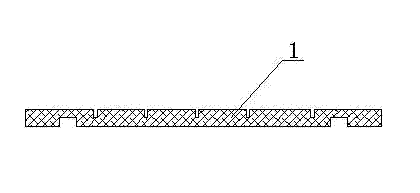

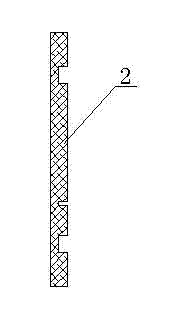

[0040] In the figure: 1. Upper horizontal frame, 2. Vertical frame, 3. Formwork, 4. Vertical reinforcement, 5. Horizontal distribution reinforcement, 6. Connecting reinforcement.

[0041] The semi-prefabricated construction process steps of the concrete thin-walled back eaves are as follows:

[0042] Decomposition Design of Semi-prefabricated Components for Lower Return Eaves

[0043] Before the construction of the semi-prefabricated components, the lower eaves should be comprehensively analyzed according to the design drawings, and the lower eaves should be reasonably decomposed into structural units with simple structures and convenient for construction. The height of the semi-prefabricated components is the designed height of the lower eaves, and the length is 800mm ;

[0044] template making

[0045] Formwork 3 four-frame connection adopts groove-and-groove form, leave the designed steel bar spacing on the upper horizontal frame 1 of the formwork, and cut out the designe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com