Self-elevating outer frame turning device for bridge high pier

A high-pier, self-elevating technology, used in bridges, bridge parts, bridge construction, etc., can solve problems such as waste, formwork is not a turnover material, and formwork cannot be used completely, achieving green construction, avoiding construction waste, and easier quality control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

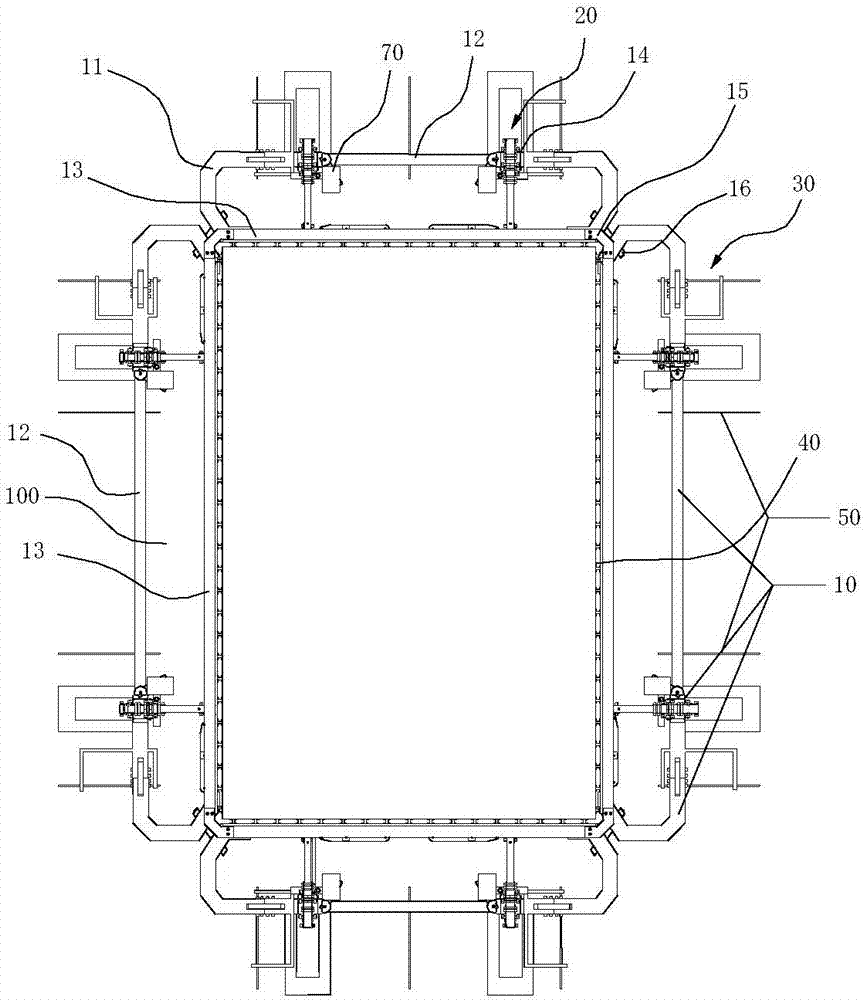

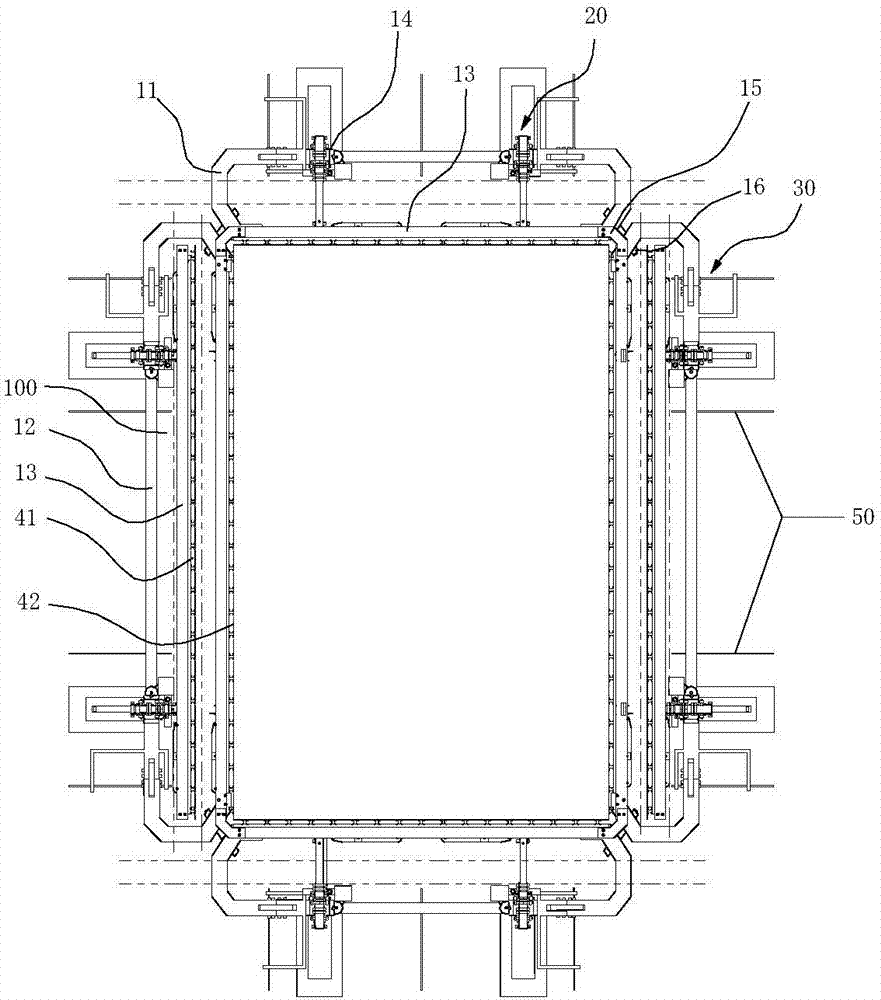

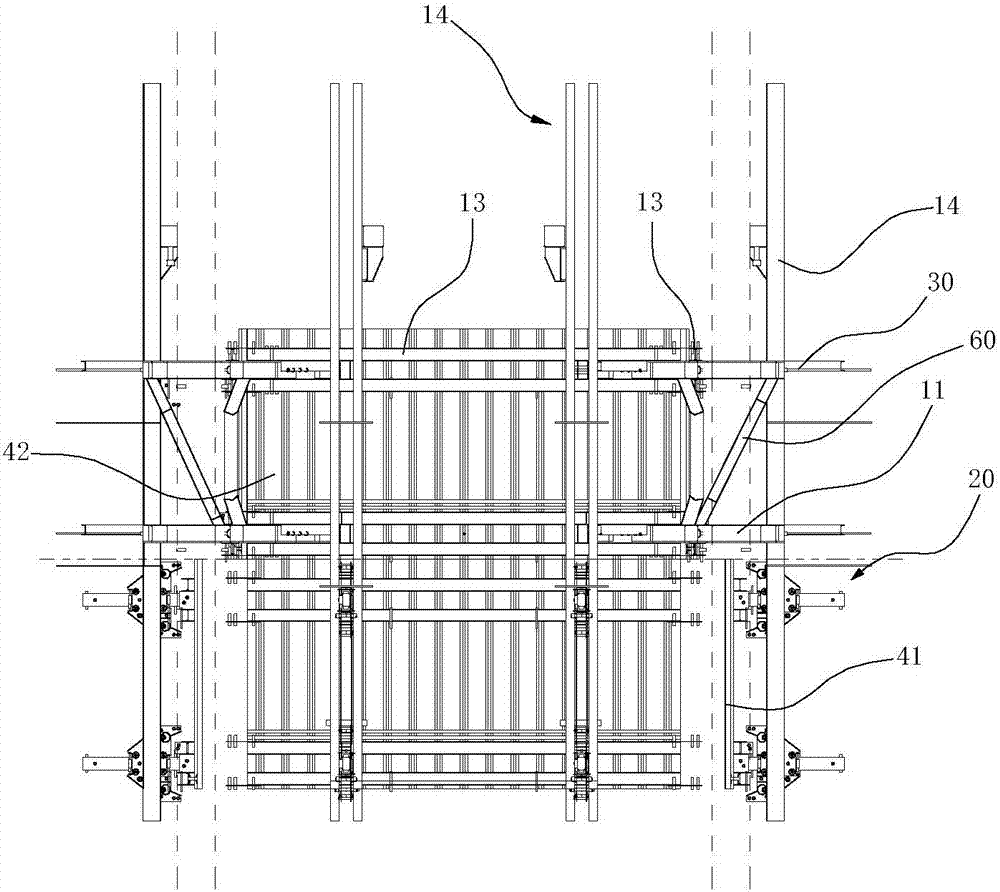

[0049] Such as Figure 1 to Figure 12 As shown, the high pier self-elevating outer frame turning device of the present invention includes an outer support system 10, a telescopic device 20, an upper formwork system 42 and a lower formwork system 41; the upper formwork system 42 is located in the lower formwork system 41 the top of

[0050] Both the upper formwork system 42 and the lower formwork system 41 include a formwork 40 that surrounds the pouring cavity of the high pier of the bridge; 13. The reinforced horizontal back flutes 13 on two adjacent formworks 40 are all connected by reinforced horizontal back flute connectors 15, so that the reinforced horizontal back flute 13 is tightly hugged on the outer surface of the template 40;

[0051] The upper and lower ends of each template 40 of the upper formwork system 42 are provided with an outer sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com