Intelligent robot with stamping and carrying functions

A technology of intelligent robots and motion mechanisms, applied in the field of intelligent robots, can solve problems such as hidden safety hazards and industrial accidents, and achieve the effects of convenient operation, reduced labor intensity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

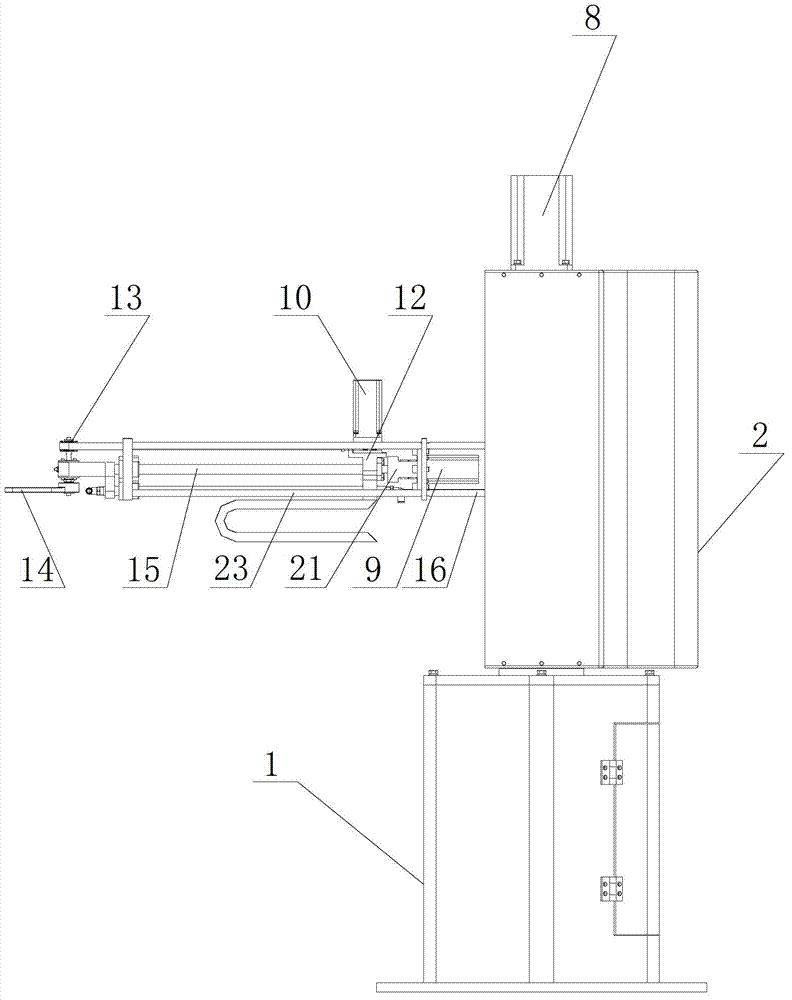

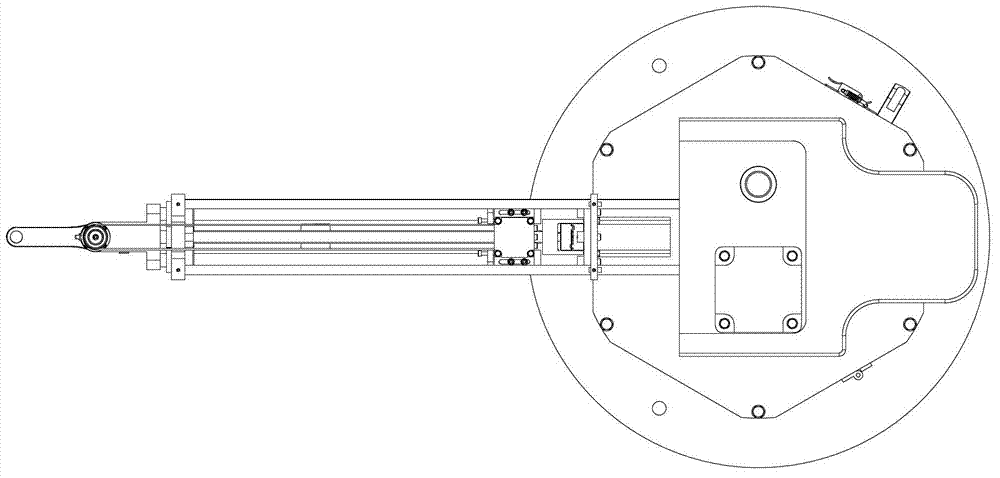

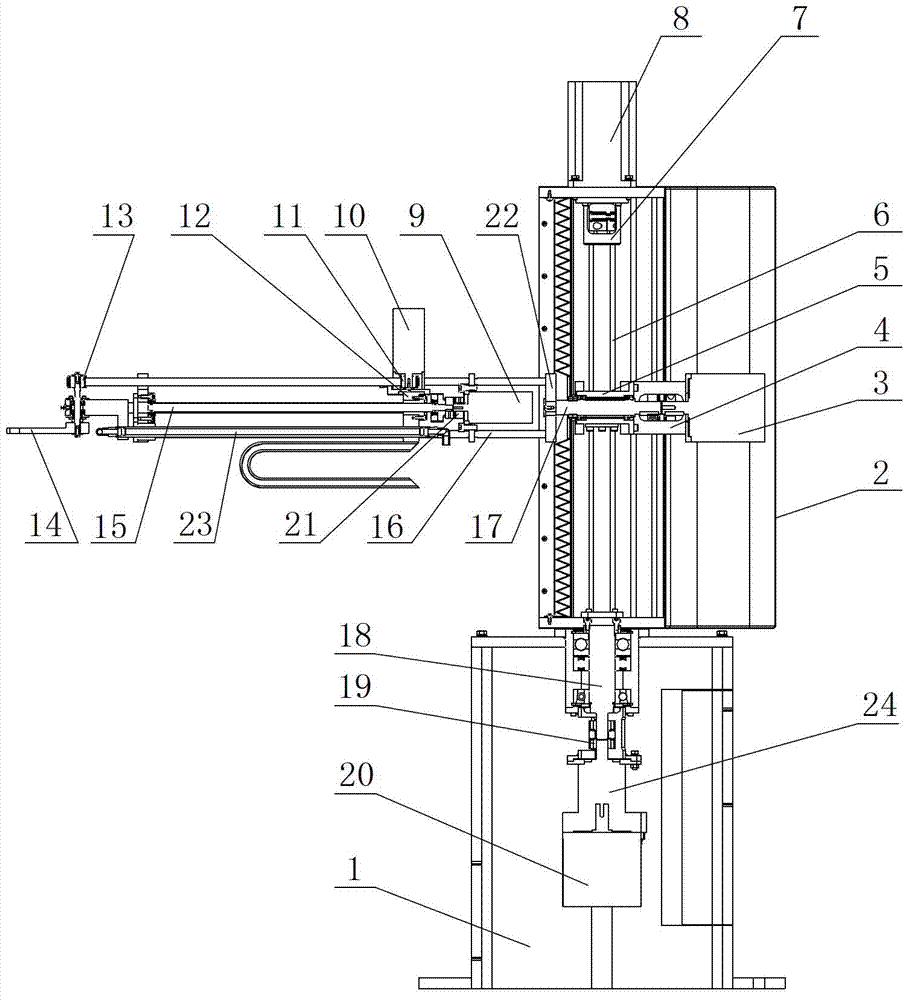

[0025] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0026] Please refer to Figures 1 to 7 As shown, in this embodiment, a stamping and conveying intelligent robot includes a base 1 and a rear cover 2 arranged above the base 1, a side of the rear cover 2 is horizontally provided with a mechanical arm 16, and the base 1 is provided with a swing arm movement mechanism that drives the mechanical arm 16 to rotate axially up and down. The swing arm movement mechanism includes a servo motor 20 and a main shaft 18. The servo motor 20 is electrically connected to a PLC programmable controller, and it is connected to The shaft device 19 is connected to the main shaft 18, and the main shaft 18 is fixedly connected to the rear cover 2; the rear cover 2 is provided with a turning mechanism for driving the left and right axial rotation of the mechanical arm 16 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com